Alginate Substitutes: Rationale for Their Use

The irreversible hydrocolloid that we commonly refer to as alginate is extensively used for study casts, master casts and working models for the fabrication of intraoral appliances.1 Alginate is the most common impression material used for creating the opposing model for crown & bridge, but it has many shortcomings as an ideal impression material. The ideal impression material should reproduce oral detail accurately; have high tear strength; have reasonable working and setting time; be biocompatible; be dimensionally stable; allow multiple pours; and not be affected in its accuracy by disinfection.2

Background on Alginates

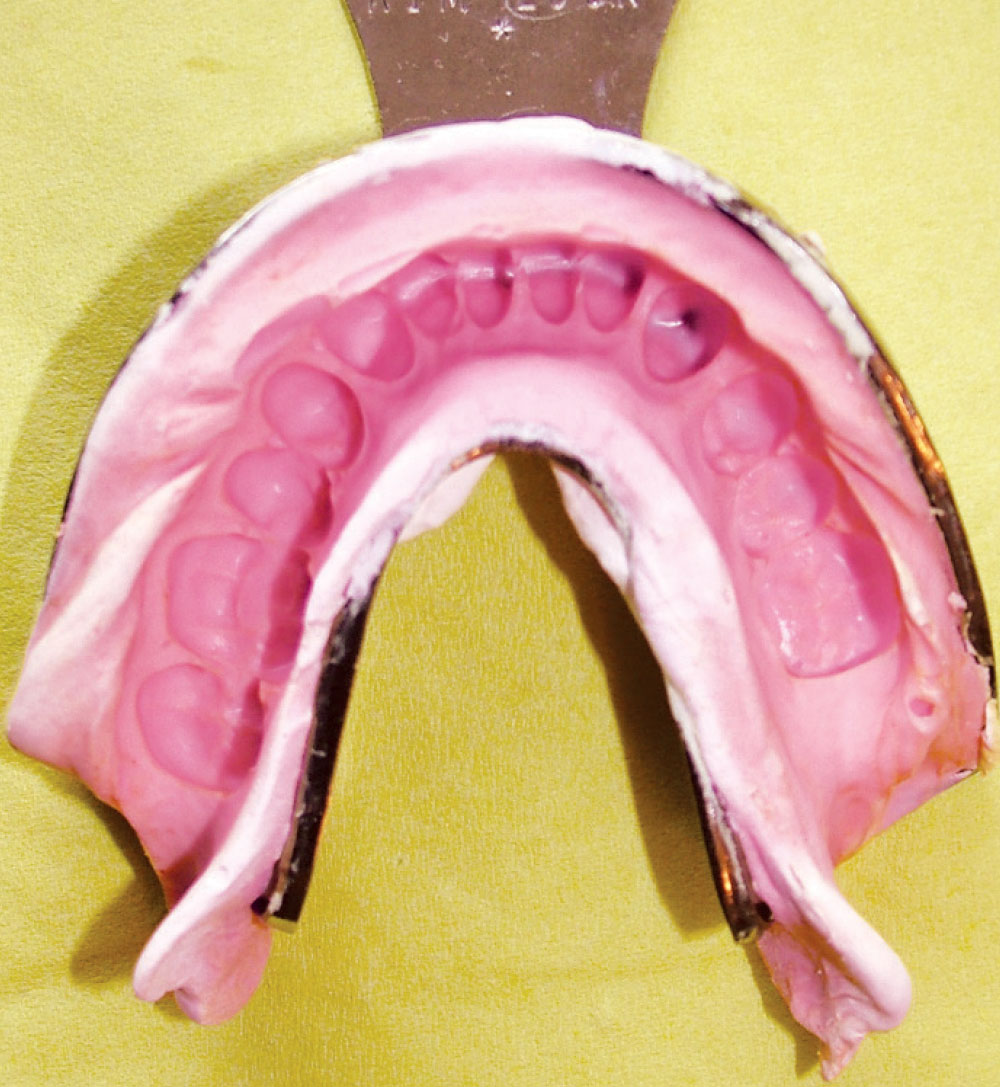

Due to its hydrophilic nature, alginate takes a good impression in a moist environment.3 However, this very feature — which is so important to clinicians — creates one of the most severe limitations for its use. This property creates an impression that is not dimensionally stable due to environmental humidity and temperature.4,5,6,7 This feature of hydrophilicity also affects the stability of polyethers, which can change dimensionally (larger by 30 to 240 µm, or smaller by 20 to 120 µm) depending on humidity.8 Polyether impressions and alginate impressions wrapped in moist towels should never be shipped to the laboratory in the same polybag because the polyether impression can absorb water from the alginate impression or its wet wrap. Alginate impressions should immediately be poured in dental stone for maximum accuracy because of the material’s ability to imbibe or lose moisture. After 10 minutes of storage time, alginate begins to distort. After one to three hours, it cannot be used for many clinical purposes, especially fixed prosthodontics (Fig. 1).9

The stability of alginates is also affected by the reaction of syneresis, in which fibril cross-linking continues, creating a contraction with time and an exudation of water. This reaction, therefore, necessitates immediate pour-up of the alginate. Irreversible hydrocolloids such as alginate can be poured up only once because of hydrophilicity.

Hydrophilicity also creates a monumental problem with disinfection of irreversible hydrocolloid, with hundreds of research articles looking at types of disinfectants in various combinations with a multitude of alginates. These investigations show that disinfection can create severe effects on dimensional accuracy, with immersion creating the greatest inaccuracy, as well as an effect on the surface quality of the casts produced.10,11,12,13,14 Alginate has a low tear strength and snags easily, especially in deep undercuts and pontic areas. It has a tendency to stick to teeth, with possible alginate tears on removal of the alginate. Polishing or prophylaxis of the teeth exacerbates the problem, preventing the alginate material from wetting the teeth and reproducing detail.15 If the teeth are dried from taking one impression, retaking a good, detailed second impression of the same arch is impossible.2

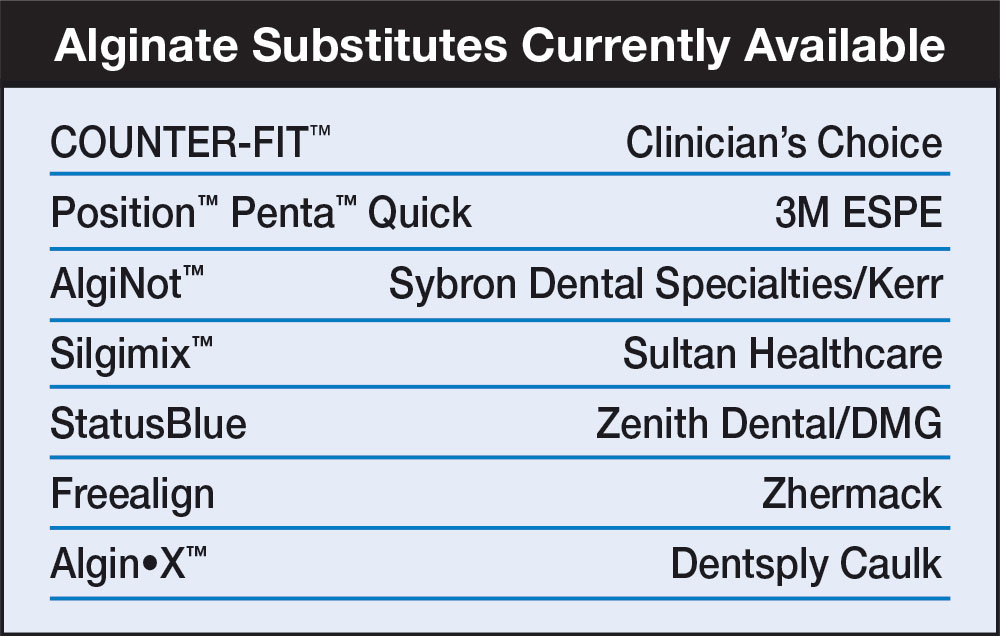

If one adds the clinical variability of the inaccuracy of the amount of powder used in the mix (Fig. 2), the amount and temperature of the water (both which affect thixotropy and working time) (Fig. 3), the effects of mixing methods on the mechanical properties of alginates,16 the effect of type and design of tray on clinical accuracy,17,18 the effects of using adhesives (Fig. 4),19,20 and the exposure to hazardous dust,1,21 it is not surprising that alginate substitutes are becoming more popular (Table 1, Fig. 5).

Alginate Substitutes

Alginate substitutes are low-cost polyvinylsiloxanes (PVS) that have the same characteristics of higher priced PVS materials used for final impressions in fixed prosthodontics. Christensen describes these alginate substitutes as accurate, clean to use (no bowl to clean, no dust), flavorless (flavor increases salivation, which is not favorable), odorless and as having the ability to delay pouring or to make additional pours of the same impression (Fig. 6).22 Multiple studies have demonstrated that PVS is the most dimensionally stable impression material23,24 and has a higher tear strength than alginate. Unlike alginates, they are not affected by disinfection techniques.25

The ability to pour these alginate substitutes at any time provides a whole new window of opportunity4 and now allows the clinician to send these opposing impressions along with the final crown & bridge impression to the laboratory, eliminating the need to pour, separate and trim the model in the dental office. Not only does this save the office a tremendous amount of time and money, but now this process is a billable procedure as part of the laboratory fee for the crown & bridge case. Currently, most dentists absorb the cost of fabricating the opposing model and do not bill it as a separate procedure. Because the PVS has better surface replication of the opposing dentition, and because the variables around mixing the dental stone are more closely monitored in the laboratory, the opposing model will be much more detailed and accurate.

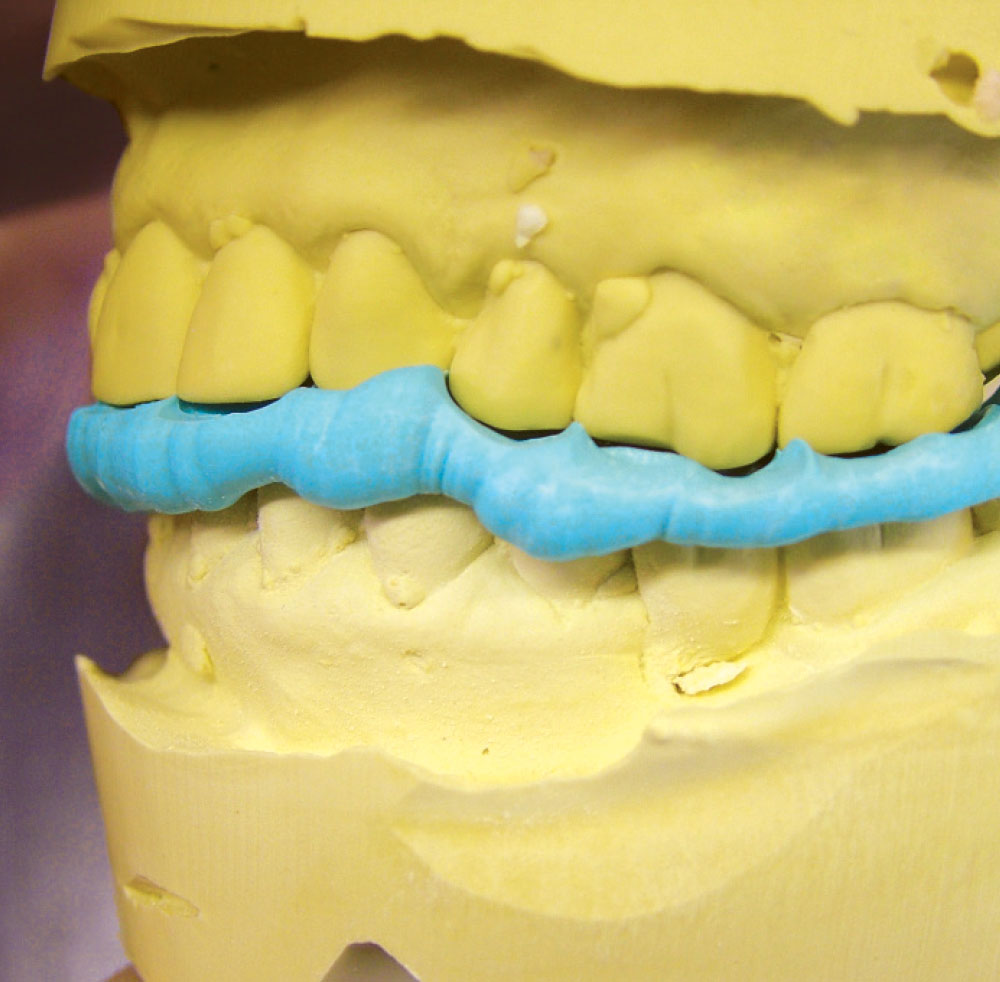

One of the main driving forces of a change in direction from opposing models produced from alginate to opposing models derived from alginate substitutes in fixed prosthodontics is the severe mismatch of accuracy between modern bite registration materials and alginate-driven stone models. Boksman26 looked at PVS bite registration materials and the need for extensive occlusal adjustments on crown & bridge prostheses, showing the severe open-bite mounting that can result when using a highly accurate PVS bite registration with a poorly detailed alginate-driven stone model (Fig. 7). Using PVS for the final impression, for the bite registration and for the opposing models eliminates the dimensional mismatch between materials, resulting in more accurate mounting of the case and less clinical necessity for occlusal adjustments (Figs. 8–11).

The surface replication of the casts is also much smoother than models derived from alginate impressions. Even though the cost of the PVS alginate substitutes is higher than the irreversible hydrocolloid alginate materials, the impression is easier to take due to the thixotropic nature of these materials, the time and cost of pouring up the opposing model can be eliminated, the impression can be repoured if the model is broken or chipped, there is increased office efficiency, the opposing model is more accurate, the bite registration actually fits, and the time and frustration of adjusting the final prosthesis is minimized. These many benefits more than compensate for the extra cost. In addition, the clinician can now (in some cases) bill this as part of the laboratory procedure.

Dr. Len Boksman is adjunct clinical professor at the Schulich School of Medicine and Dentistry and maintains a private practice in London, Ontario, Canada. He is also a paid part-time consultant to Clinical Research Dental Inc. and Clinician’s Choice. Contact him at lboksman@clinicalresearchdental.com or 519-641-3066, ext. 292.

Gregg Tousignant, CDT, is technical support manager for Clinical Research Dental Inc. Email him at gtousignant@clinicalresearchdental.com

Reprinted by permission of Dentistry Today, ©2009 Dentistry Today. “DOCTOR-TECHNICIAN PERSPECTIVES: Alginate Substitutes: Rationale for Their Use,” by Leendert Boksman, DDS, and Gregg Tousignant, CDT: Dentistry Today, Vol. 28, No. 4, 04/09, pp 104-105.

References

- ^ Pace SL. Polyvinyl impression materials vs. alginate impression materials. Contemp Dental Assisting. 2006 Feb:20-3.

- ^Rubel BS. Impression materials: a comparative review of impression materials most commonly used in restorative dentistry. Dent Clin North Am. 2007 Jul;51(3):629-42.

- ^Cohen BI, Pagnillo M, Deutsch AS, Musikant BL. Dimensional accuracy of three different alginate impression materials. J Prosthodont. 1995 Sep;4(3):195-9.

- ^Perry R. Using polyvinyl impressions for study models: a case report. Dent Today. 2004 Oct;23(10):106-7.

- ^Chen SY, Liang WM, Chen FN. Factors affecting the accuracy of elastometric impression materials. J Dent. 2004 Nov;32(8):603-9.

- ^Straw J, Iuorno F, Lindauer S. Dimensional stability of Kromopan, an irreversible hydrocolloid impression material. Presented at 32nd Annual Meeting and Exhibition of the ADR; March 12-15, 2003; San Antonio, TX. Abstract 0290. Available at : http://iadr.confex.com/iadr/2003SanAnton/techprogram/abstract_26049.html Accessed Feb 3, 2009.

- ^Bayindir F, Yanikoğlu N, Duymuş Z. Thermal and pH changes, and dimensional stability in irreversible hydrocolloid impression material during setting. Dent Mater J. 2002 Jun;21(2):200-9.

- ^Kanehira M, Finger WJ, Endo T. Volatilization of components from and water absorption of polyether impressions. J Dent. 2006 Feb;34(2):134-8.

- ^Nichols PV. An investigation of the dimensional stability of dental alginates. Sydney, Australia: Faculty of Dentistry, University of Sydney;2006. Available at: http://hdl.handlenet/2123/1270. Accessed Feb 23, 2009.

- ^Taylor RL, Wright PS, Maryan C. Disinfection procedures: their effect on the dimensional accuracy and surface quality of irreversible hydrocolloid impression materials and gypsum casts. Dental Mater. 2002 Mar;18(2):103-10.

- ^Jagger DC, Al Jabra O, Harrison A, et al. The effect of a range of disinfectants on the dimensional accuracy of some impression materials. Eur J Prosthodont Restor Dent. 2004 Dec;12(4):154-60.

- ^Machado C, Johnston W, Coste A, et al. Simulated clinical compatibility of disinfectant solutions with alginate impression materials. Presented at: IADR General Session & Exhibition; June 28-July 1, 2006; Brisbane, Australia. Abstract 2467. Available at: http://iadr.confex.com/iadr/2006Brisb/techprogram/abstract_82984.htm. Accessed Feb 23, 2009.

- ^Muller-Bolla M, Lupi-Pégurier L, Velly AM, Bolla M. A survey of disinfection of irreversible hydrocolloid and silicone impressions in European Union dental schools: epidemiologic study. Int J Prosthodont. 2004 Mar-Apr;17(2):165-71.

- ^Lu JX, Zhang FM, Chen YM, Qian M. The effect of disinfection on dimension stability of impressions [in Chinese]. Shanghai Kou Qiang Yi Xue. 2004 Aug;13(4):290-2.

- ^Phoenix RD, Cagna DR, DeFreest CE. Stewart’s clinical removable partial prosthodontics. 3rd ed. Chicago: Quintessence Publishing; 2003. p. 162-7.

- ^Frey G, Lu H, Powers J. Effect of mixing methods on mechanical properties of alginate impression materials. J Prosthodont. 2005 Dec;14(4):221-5.

- ^Mendez AJ. The influence of impression trays on the accuracy of stone casts poured from irreversible hydrocolloid impressions. J Prosthet Dent. 1985 Sep;54(3):383-8.

- ^Gordon GE, Johnson GH, Drennon DG. The effect of tray selection on the accuracy of elastomeric impression materials. J Prosthet Dent. 1990 Jan;63(1):12-5.

- ^Leung KC, Chow TW, Woo EC, Clark RK. Effect of adhesive drying time on the bond strength of irreversible hydrocolloid to stainless steel. J Prosthet Dent. 1999 May;81(5):586-90.

- ^Smith SJ, McCord JF, Macfarlane TV. Factors that affect the adhesion of two irreversible hydrocolloid materials to two custom tray materials. J Prosthet Dent. 2002 Oct;88(4):423-30.

- ^Craig RG. Review of dental impression materials. Adv Dent Res. 1988 Aug;2(1):51-64.

- ^Christensen GJ. Ask Dr. Christensen. Dent Econ. 2008 Mar;98:66.

- ^Karthikeyan K, Annapurni H. Comparative evaluation of dimensional stability of three types of interocclusal recording materials: an in vitro study. J Indian Prosthodont Soc. 2007;7(1):24-7.

- ^Boksman L. Eliminating variables in impression-taking. Ontario Dentist. 2005 Dec:22-5.

- ^Waranowicz MT, O’Keefe KL. Alginates and alginate substitutes. The Dental Advisor. 2007;24:1-7.

- ^Boksman L. Point of care: how do I minimize the amount of occlusal adjustment necessary for a crown? J Can Dent Assoc. 2005;71:494-5.