BruxZir® NOW Case of the Week: Episode 151

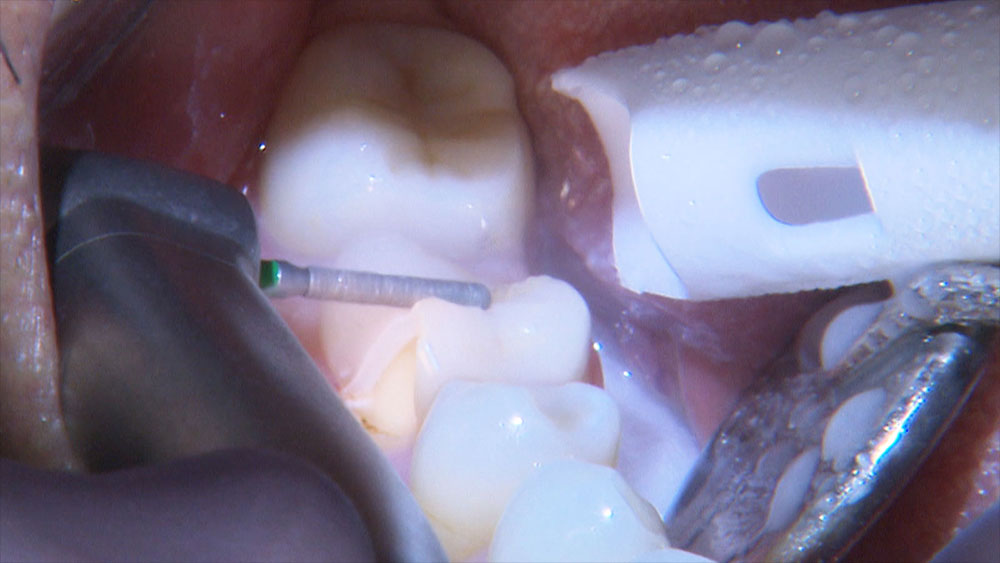

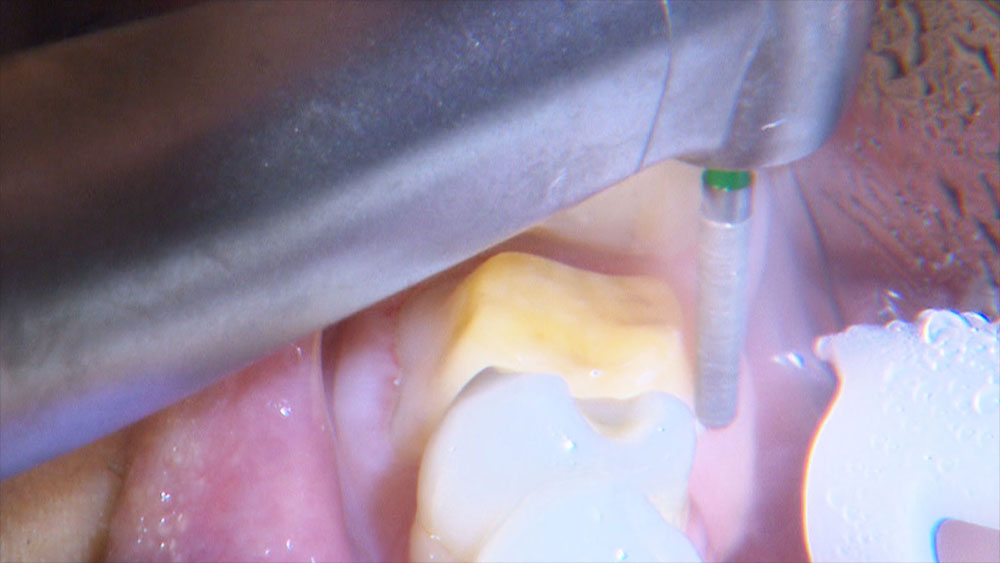

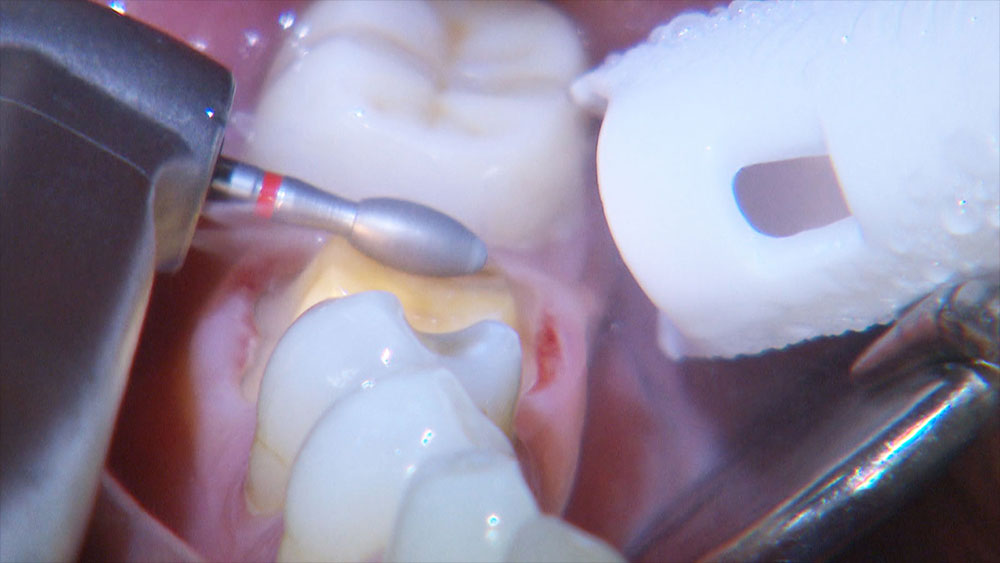

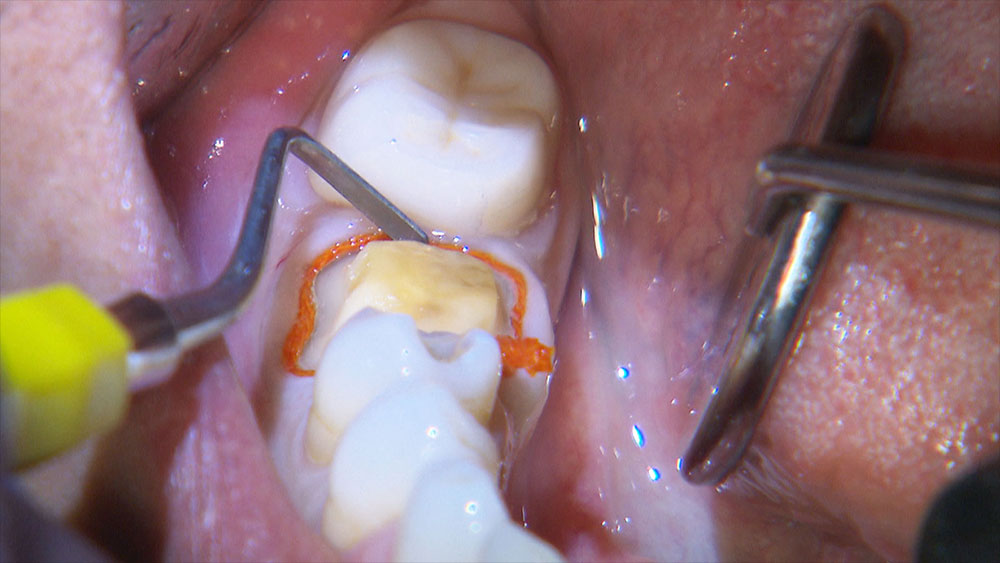

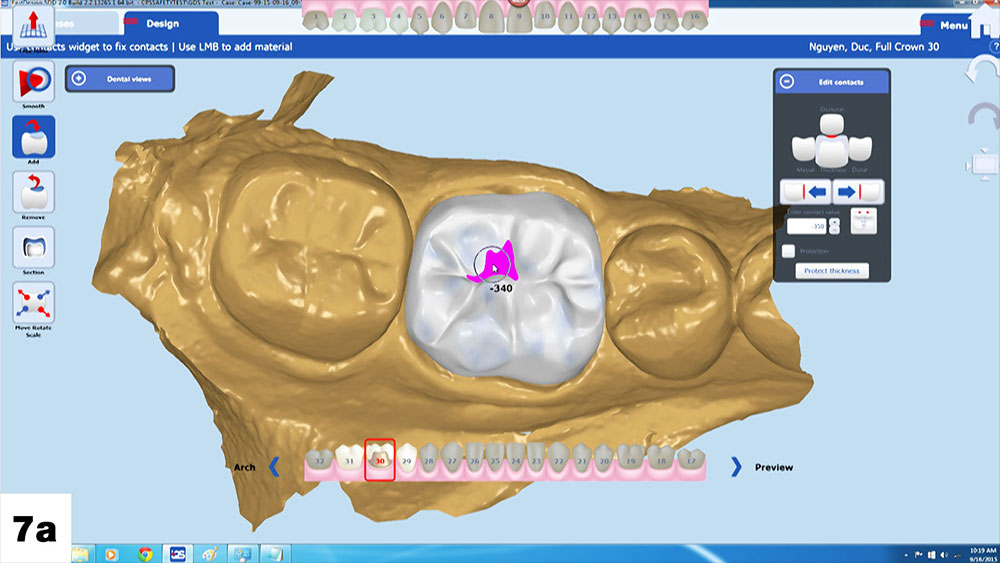

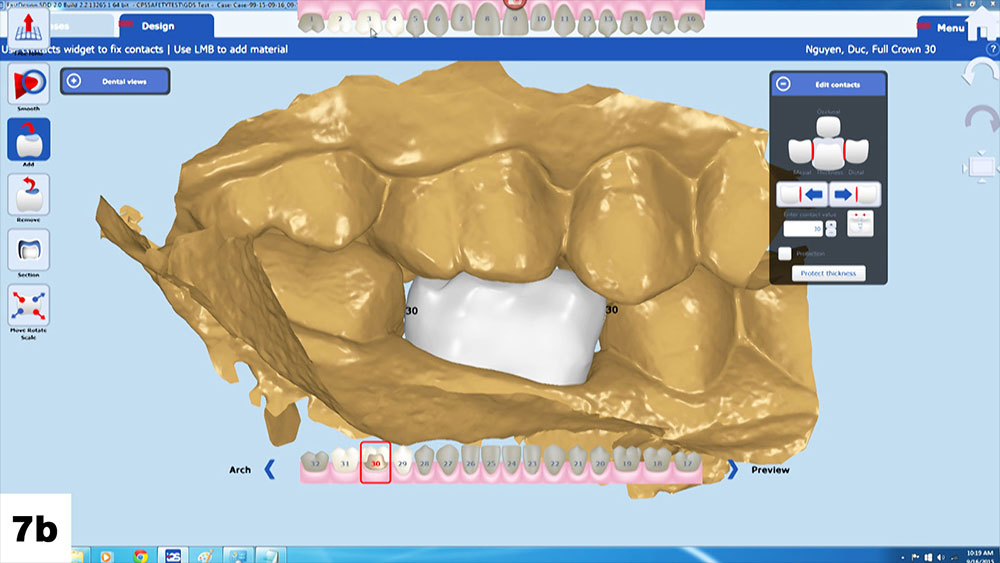

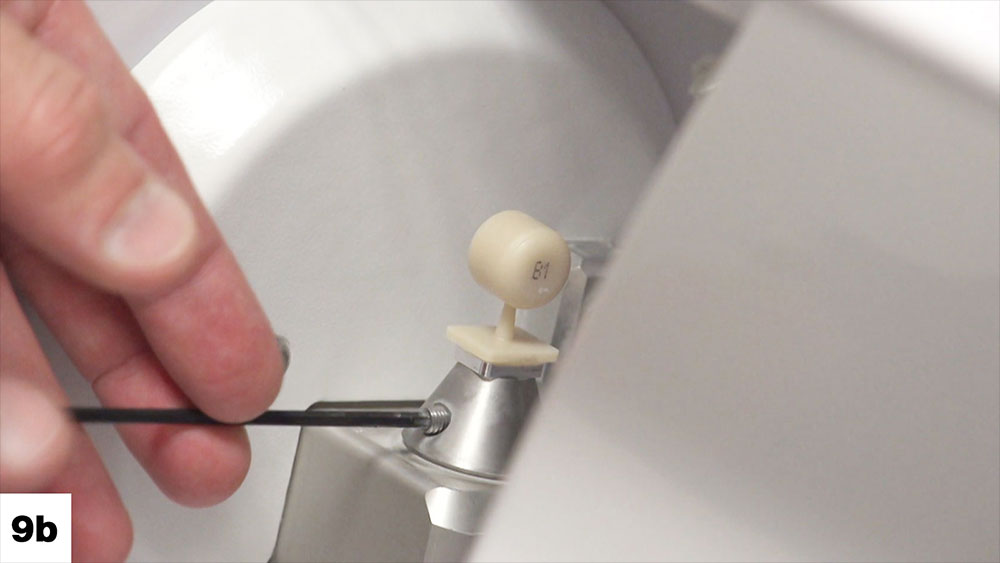

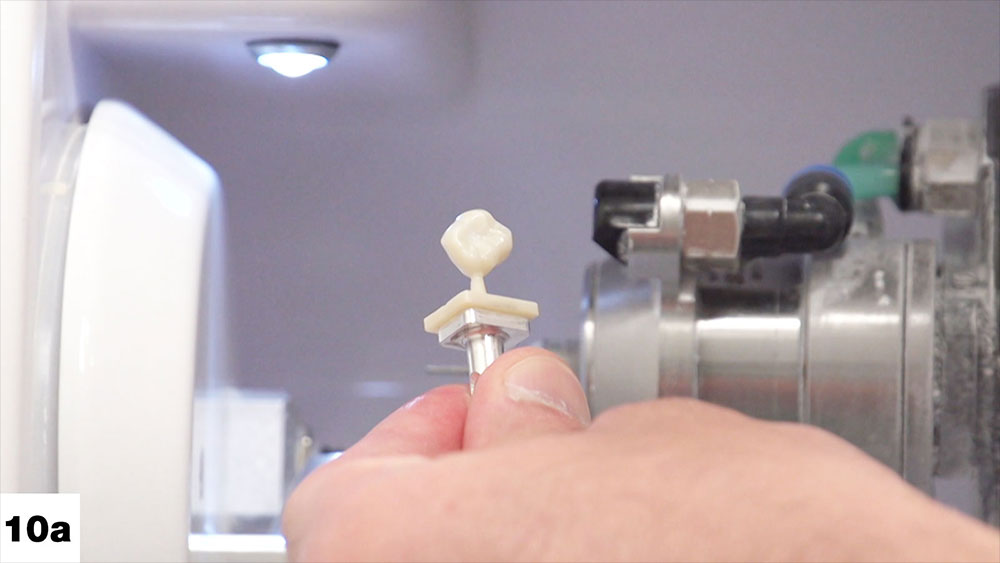

My clinical challenge in this Case of the Week was a patient’s request to have a crown replaced in a timely manner so that we could complete treatment in one visit. This desire presented an ideal situation to clinically test a new version of BruxZir® Solid Zirconia. The available formulations of BruxZir Solid Zirconia have already proven themselves to be extremely strong materials and are utilized by clinicians across the country. Recently, we have been developing a product called BruxZir NOW, and with this chairside, fully sintered zirconia restoration, I can provide the patient with an extremely strong crown in a very short amount of time.

Recently, we have been developing a product called BruxZir NOW, and with this chairside, fully sintered zirconia restoration, I can provide the patient with an extremely strong crown in a very short amount of time.

Conclusion

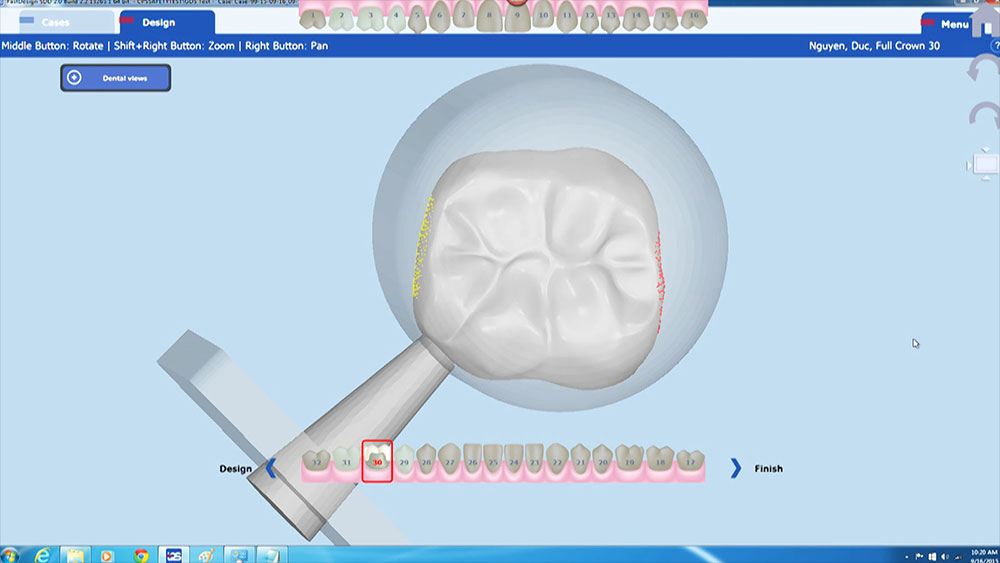

With BruxZir NOW, you can pare down your chair time to a single appointment for a restoration, while still providing the established brawn of BruxZir. This chairside, fully sintered zirconia restorative material joins an array of lab-verified innovations from our Research & Development department, where a team of 75 includes material scientists, technicians, clinicians and experts with Ph.D.s. The R&D team has been hard at work making certain the chairside-milled BruxZir NOW is clinically sound, and you can learn more about their advancements at bruxzir.com.