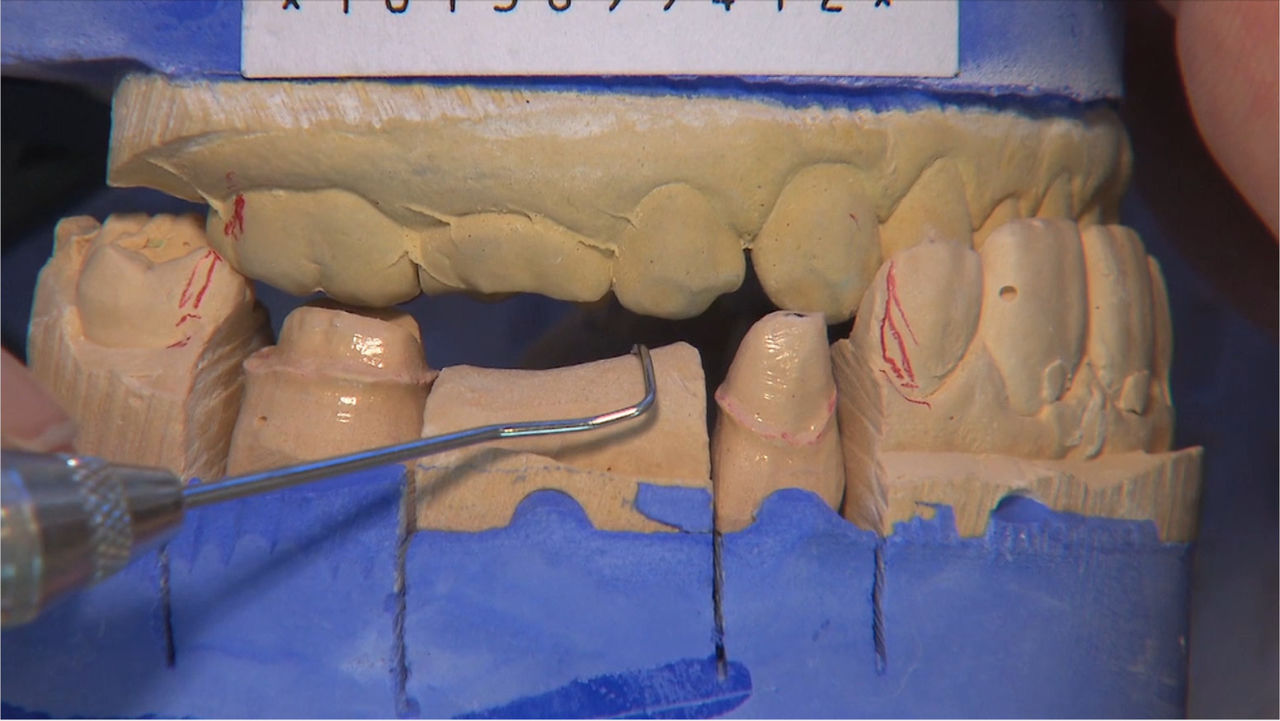

To summarize the above, the key differences between zirconia and PFM crowns are the number of layers and the composition of said layers. Zirconia crowns are made from a single high-strength material, while PFMs are made from two materials: metal and a layering ceramic. Ultimately, the material makeup significantly impacts the definitive performance of a restoration.

Take PFMs, for example. Historically, they have displayed high rates of chipping, fracturing and shearing off of the layering ceramic. There are two primary reasons behind these breakages. First, because the ceramic layer is so thin, the material is less durable. Second, there are a difference between the thermal expansion characteristics of the substructure metal and those of the layering ceramic, which means that the layers expand and contract at differing rates during manufacturing. This imparts imperfections and weaknesses into the finalized restorations, especially at the location where the ceramic and metal meet.

Zirconia crowns, on the other hand, are milled from a solid block of zirconia and sintered as fully shaped restorations. The monolithic nature of the material means that all areas of the restoration share the same material characteristics, eliminating the issues observed in PFMs. Moreover, zirconia imparts significant performance characteristics, having nearly 10 times the flexural strength of an average feldspathic layering ceramic.3,4

However, while zirconia is substantially stronger than the ceramics used for PFM crowns, the monolithic material does have a weakness: Zirconia bridges with long spans in an area with limited vertical space may fracture over time, an issue arising due to the bridge connectors having small volume. At Glidewell, for these bridges, we typically recommend that dentists use PFM restorations because their metal substructure ensures a longer-lasting solution in those compact areas.