- Situates margins at or just below gingival surface to ease crown delivery and cement cleanup

- Creates a natural emergence profile and optimizes soft-tissue contours

- Available in titanium, gold-tone titanium, zirconia with titanium base, and gold alloy

- NEW milled grooves for improved crown retention

Custom Abutments

*Price is per unit and does not include shipping or applicable taxes.

Glidewell's custom abutments are precisely milled using CAD/CAM technology to facilitate a natural-looking emergence profile, optimize crown margins, and enable a smooth, efficient delivery appointment for cementable implant restorations.

Simplify Implant Crown Delivery and Get Predictable Results

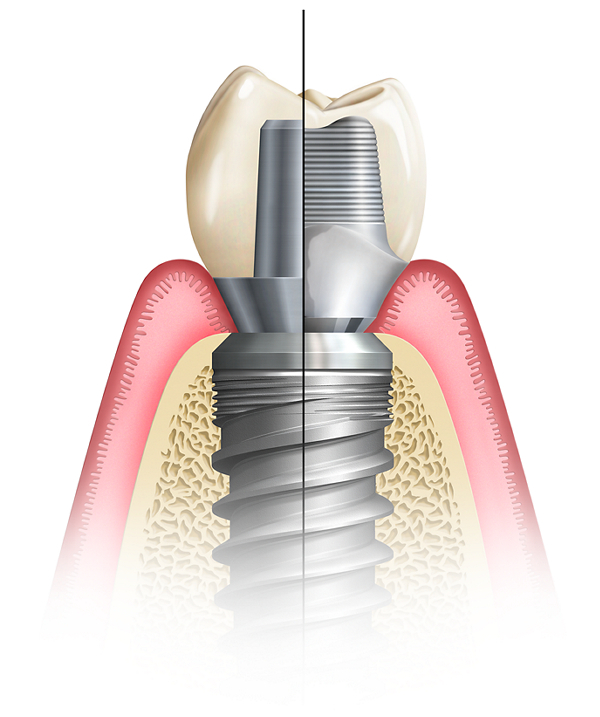

For dentists seeking a smooth, efficient final delivery appointment for cementable implant restorations, custom abutments offer a precise, predictable solution. Glidewell's custom abutments are precisely milled using CAD/CAM technology to facilitate a natural-looking emergence profile and optimize gingival contours and crown esthetics. Due to their strength, titanium custom abutments are commonly used in all regions of the mouth. Zirconia abutments with titanium bases are commonly used to optimize esthetics in the anterior.

Available for most major implant systems, custom abutments are designed to align with the gingival anatomy of the individual patient, ensuring a precise, comfortable fit. Dental CAD software is used to position the crown margins at or just below the gingival surface, easing restoration delivery and the cleanup of excess cement.

Custom Abutment vs. Stock Abutment

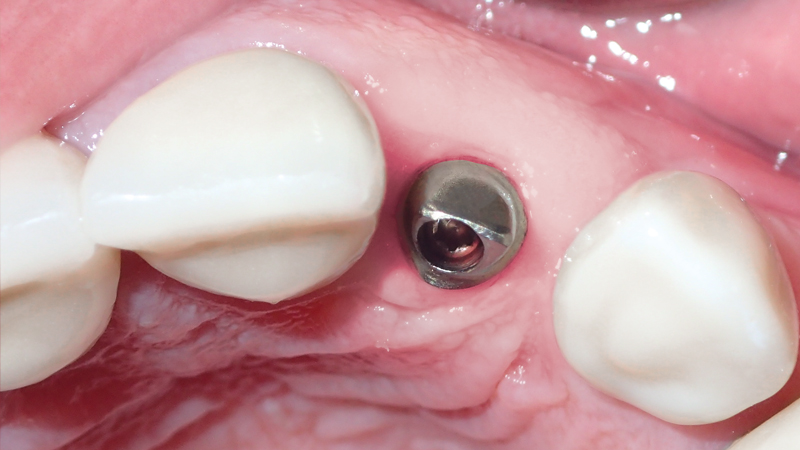

The tissue-level junction established by a custom abutment allows for easier cement removal than a stock abutment with shallow margins.

Clinical Studies

Indications

Custom abutments are prosthetic components that connect directly to endosseous dental implants and are intended for use as an aid in prosthetic rehabilitation of missing teeth.

Material Composition

Titanium, gold alloy, or zirconia with titanium base

Number of Implant Restorations Produced

2 million

In-Lab Working Times

- Standard: 8 days

Pricing

|

Titanium custom abutment1

|

$318.00 |

|

from digital file1

|

$298.00 |

|

Gold-Tone Titanium abutment1

|

$318.00 |

|

from digital file1

|

$298.00 |

|

Hybrid Zirconia abutment with Ti-Base1

|

$318.00 |

|

from digital file1

|

$298.00 |

|

BIOMET 3i™ Encode® Titanium abutment

|

$381.00 |

|

BIOMET 3i™ Encode® Gold-Colored Nitride-Coated Titanium abutment

|

$381.00 |

|

BIOMET 3i™ Encode® Hybrid Zirconia Abutment with Ti-Base

|

$381.00 |

|

Gold alloy implant abutment2

|

$632.003 |

|

Prepare existing implant abutment

|

$80.00 |

Flat-rate price available for BioHorizons® Tapered Internal; BIOMET 3i Certain®; CAMLOG® SCREW-LINE; DENTSPLY Implants ANKYLOS® C/X, ASTRA TECH Implant System® and ASTRA TECH Implant System® EV; Glidewell HT™ Implant System; Hahn™ Tapered Implant System; HIOSSEN® HG System; Inclusive® Tapered Implant System; MegaGen AnyRidge® Implant System; MIS® C1 Implant System; Nobel Biocare Brånemark System® RP, NobelActive® and NobelReplace®; Straumann® Bone Level, Bone Level SC and Tissue Level; and Zimmer Dental Screw-Vent®. For digitally submitted cases, Inclusive Titanium Scan Bodies must be used to receive flat-rate pricing. Prices may vary for other implant systems due to the need for original equipment manufacturer (OEM) components.

Available for most major implant systems. Waxing sleeve and final screw not included.

Pennyweight pricing applies when precious metal implant abutment is over 2 pennyweights.

Pricing is subject to change and does not include shipping or applicable taxes.

Implant System Compatibility

Flat-rate price available for BioHorizons® Tapered Internal; BIOMET 3i™ Certain®; CAMLOG® SCREW-LINE; DENTSPLY Implants ANKYLOS® C/X, ASTRA TECH Implant System® and ASTRA TECH Implant System® EV; Glidewell HT™ Implant System; Hahn™ Tapered Implant System; HIOSSEN® HG System; Inclusive® Tapered Implant System; MegaGen AnyRidge® Implant System; MIS® C1 Implant System; Nobel Biocare Brånemark System® RP, NobelActive® and NobelReplace®; Straumann® Bone Level, Bone Level SC and Tissue Level; and Zimmer Dental Screw-Vent®. Prices may vary for other implant systems due to the need for original equipment manufacturer (OEM) components.

Inclusive is a registered trademark of Prismatik Dentalcraft, Inc. Glidewell HT and Hahn are trademarks of Prismatik Dentalcraft, Inc. All other trademarks are property of their respective owners.

Policies & Warranty

NO-FAULT REMAKE POLICY: Glidewell is pleased to process all remakes or adjustments at no additional charge if requested within the warranty period and accompanied by the return of the original appliance.

LIMITED WARRANTY/LIMITATION OF LIABILITY. Glidewell (“the lab”) warrants that all dental devices (a “device”) are made according to your specification and approval in the belief that the device will be useful and MAKES NO OTHER WARRANTIES INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Subject to the return of a device that is placed and then fails, the lab will repair or replace the device without charge for the cost of materials and workmanship or refund the original price paid, at the lab’s option, for the life of the patient originally receiving the restoration from the date of placement (including replacement of a device that was made by the lab that was attached to said abutments and including a Hahn™ Tapered titanium dental implant upon request at no extra charge).

Clinical Tips

At the discretion of the clinician, utilize a temporary or permanent cement of choice and take care in removing all excess cement from around the margins of the custom abutment and implant crown.

Take an implant-level impression utilizing the preferred technique (direct, indirect, or intraoral scan).

- Remove the healing abutment from each implant and immediately replace it with an open- or closed-tray impression coping. NOTE: It’s important to seat the impression coping quickly to avoid soft-tissue collapse.

- Connect the impression coping to the implant and take a radiograph to verify that the impression coping is seated correctly.

- Inject light-body syringe material around each impression coping. Fill the tray with medium or heavy body and record the impression.

- Submit the impression to the laboratory.

For detailed instructions for open- and closed-tray impressions, see our Impression-Taking Techniques guide.