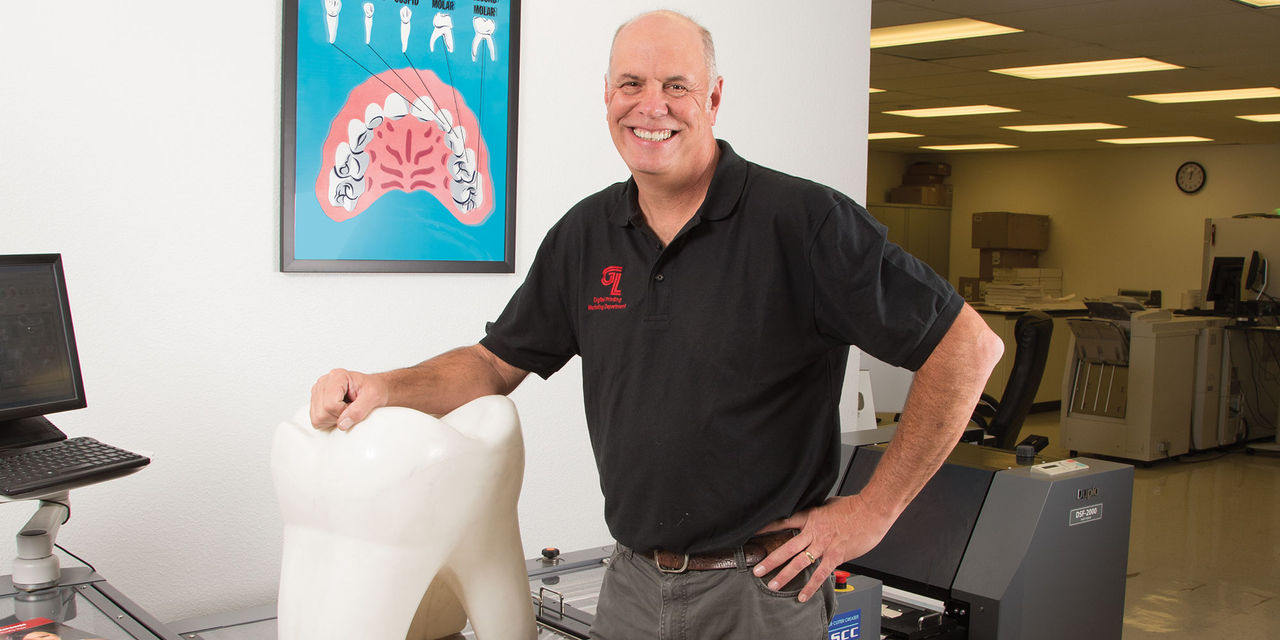

Employee Spotlight: Randall Jones

A commitment to vertical integration has been fundamental to Glidewell Dental from the very beginning. Today, Glidewell Dental employs professionals across many disciplines — from auto mechanics to research scientists — who work tirelessly at keeping the company running smoothly. This central value of vertical integration has contributed immensely to the success of Glidewell Dental, as each department offers unique professional abilities that combine to drive down the costs of high-quality products and services. One such department is the Glidewell Print Shop, a four-person team responsible for printing, cutting and binding an incredible amount of internal and external materials, including Rx books, postcards, business cards and flyers. Head of this department is Randall “Randy” Jones, a seasoned printing professional with an eye for design and all things vintage.

CHAIRSIDE MAGAZINE: Thanks for taking a break from the print shop to sit down with us, Randy.

RANDY JONES: My pleasure.

CM: Would you mind telling us a little bit about your role here at Glidewell Dental?

RJ: Sure. I am the supervisor of the Print department. When we started, I was the only employee. As we added more digital print press operators, I became more in charge of running things, but I still do the same work as the others — I’m more of a working manager in that sense.

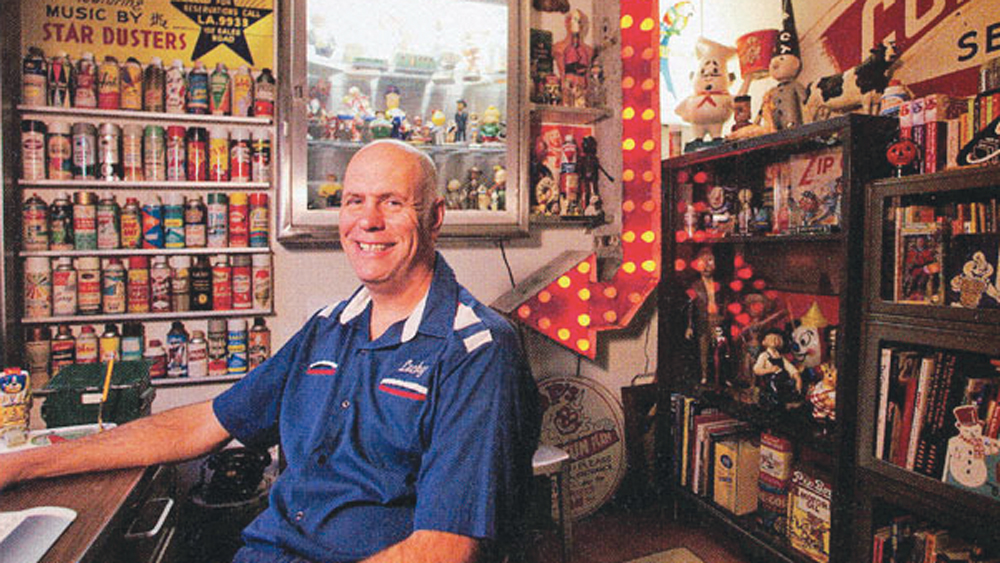

Randy Jones is head of the Glidewell Print Shop, a four-person team responsible for printing, cutting and binding internal and external materials, including Rx books, postcards, business cards and flyers. Here, he sits amongst his collectibles at home.

At the print shop, we print everything from employee business cards to internal promotional flyers and posters, Rx books, postcards and even print proofs for Chairside® magazine. We do an average of about 15,000 Rx books a week, among other things, and print the custom brochures that we send to new doctors. We produce just about anything that’s 12 inches by 18 inches or smaller; for projects with dimensions larger than that, we send to an outside printer.

We do an average of about 15,000 Rx books a week, among other things, and print the custom brochures that we send to new doctors.

CM: How did you get into the printing business?

RJ: I’ve always been into graphic design and art. In the early ’80s, a friend of my parents was working at a print shop and they had an opening, so I applied. I started at the bottom at that print shop, and at the time I was making print proofs. As I progressed, I did more composing, which is essentially building up the artwork color by color, layer by layer on a sheet of film. It was all done by hand back then, but now everything is created digitally.

Jones and the Glidewell Print Shop team oversee the production of millions of pieces of internal and external materials.

CM: You were a part of the digitization that swept through your industry. How was that?

RJ: Yes. I was interested in computers when they first started being used in printing, and my employer at the time said, “If you want to learn, I can’t pay you, but you can come in after hours.” I’d spend 3–4 hours a night teaching myself, and eventually the whole business shifted to where everything was being done on the computer.

CM: Being ahead of the curve must have paid off when it went digital. When did you join Glidewell?

RJ: I started in September 2010. It’s funny; when I saw the opening at Glidewell, I thought I’d be working in a digital press department, but in reality, they had not yet started one. I was the sole employee of the Print department, and my first few weeks were spent learning about the company and waiting for the equipment to arrive.

Though the print equipment at Glidewell Dental is largely digital today, the company benefits from having team members with decades of analog print production experience.

CM: Setting up the whole department — that’s a big task.

RJ: Certainly. It was a big step for me, from working with a team to running the show by myself, but I was given the tools and the space to build it up properly. As things progressed and we began printing higher and higher quantities, we brought on a second employee after about a year and a half. Now we’re at four employees, myself included: two during the day and two working nights. All these guys I’ve either worked with previously or known for years, so it was a no-brainer bringing them on. Everyone knows their stuff, so there’s no need for hand-holding. It’s a great team.

We all have backgrounds in the analog way of print production, so we know how to solve problems that the digital-only generation might not know of. It’s almost a lost art now, but it comes in handy more than one might think.

We all have backgrounds in the analog way of print production, so we know how to solve problems that the digital-only generation might not know of. It’s almost a lost art now, but it comes in handy more than one might think.

Jones, at home, with one of his prized collectibles, a Jolly Green Giant statue.

CM: Building upon a deep knowledge base is invaluable when starting a new department.

Glidewell Dental prides itself on vertical integration and completing all sorts of tasks — large and small — in-house. What kind of impact does that have on your job, and how do you like working at a company that does that?

RJ: I like the fact that if you need something done, it gets done by someone who works at the same company. You know they take pride in what they do — Glidewell employees seem to have a great sense of pride in their work.

For example, when we moved the print shop from one building to another, the Glidewell Woodshop worked with us in designing the cabinetry around the printing presses. So instead of moving into a building with existing storage, we arranged the equipment in a way that made the workflow more efficient, and the Woodshop crew came in and made custom cabinets around that. If we need something, we can get it fast.

CM: Working at Glidewell Dental must have its perks. Have you received dental treatment since you started working here?

RJ: Absolutely. Let’s see. I’ve gotten three or four crowns, and I got veneers to close the gap between my front teeth. I didn’t tell my wife, and came home one day with veneers — she got a little mad at me for not telling her. And I have two implants that Dr. Siamak Abai placed. The implants were placed following what was supposed to be a simple crown appointment, but it turned out I needed a root canal. Then, it became a tooth extraction appointment. An implant was supposed to be placed there, but the adjacent tooth was in bad condition, too, so that one was removed. Long story short, Dr. Abai did a double implant placement on me. I’ve gotten a fair bit of work done here. It’s definitely a great perk.

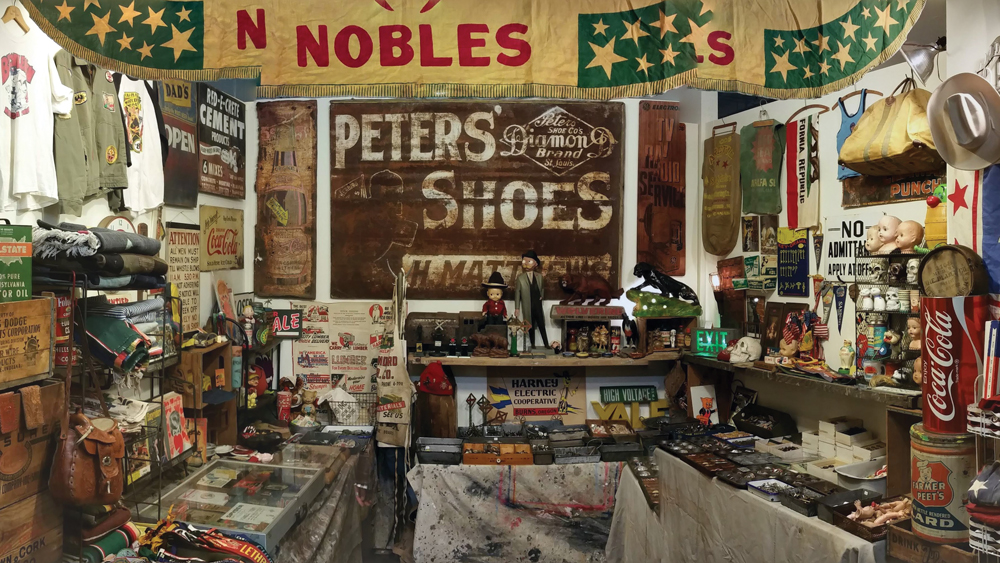

On weekends, Jones buys and sells collectibles at antique shows and swap meets.

CM: Wow. That’s quite the list.

RJ: It’s all been great work. Another great aspect of working here is the general feeling that you’re somebody and that the company cares about you. It’s clear Mr. Glidewell doesn’t take anybody for granted. You feel like you’re wanted and appreciated here. I’ve worked at places that were the complete opposite, and they just weren’t good work environments.

I’ve always felt like everyone here is willing to listen. And the fact that we get to run the presses how we see fit, because they appreciate our knowledge and experience in this area, is a plus. So, when someone from, say, the Marketing department calls and asks a question, it’s because they trust our expertise. They care what we think.

That’s a huge part of the company atmosphere in my opinion. There’s no one second-guessing your work — your experience in your field is accepted, and you’re entrusted to do what you do best.

There’s no one second-guessing your work — your experience in your field is accepted, and you’re entrusted to do what you do best.

CM: That’s good to hear. When you’re not printing, what do you do in your free time?

RJ: When I’m not at work, I’m usually running around at swap meets and antique shows on the weekends, buying and selling collectibles. That’s my second passion, I guess you could say. I’ve been married for 21 years. My wife runs a vintage toy store, and I’ve been into vintage antiques and collectibles for as long as I can remember. It’s like a big treasure hunt; my wife and I love it. And we collect, too. Our whole house is full of stuff — we have a 7-foot-tall Big Boy, a Jolly Green Giant and a Colonel Sanders.

CM: That’s fantastic. You’re a busy man, Randy. Thanks again for your time.