The Remake Debate

Mention “remakes” in a room full of laboratory owners and you know you’re in for a spirited discussion. It’s no wonder: not only do these cases-gone-wrong cut into your profits, but they can wreak havoc with your production schedule and erode the relationships you’ve built with your clients.

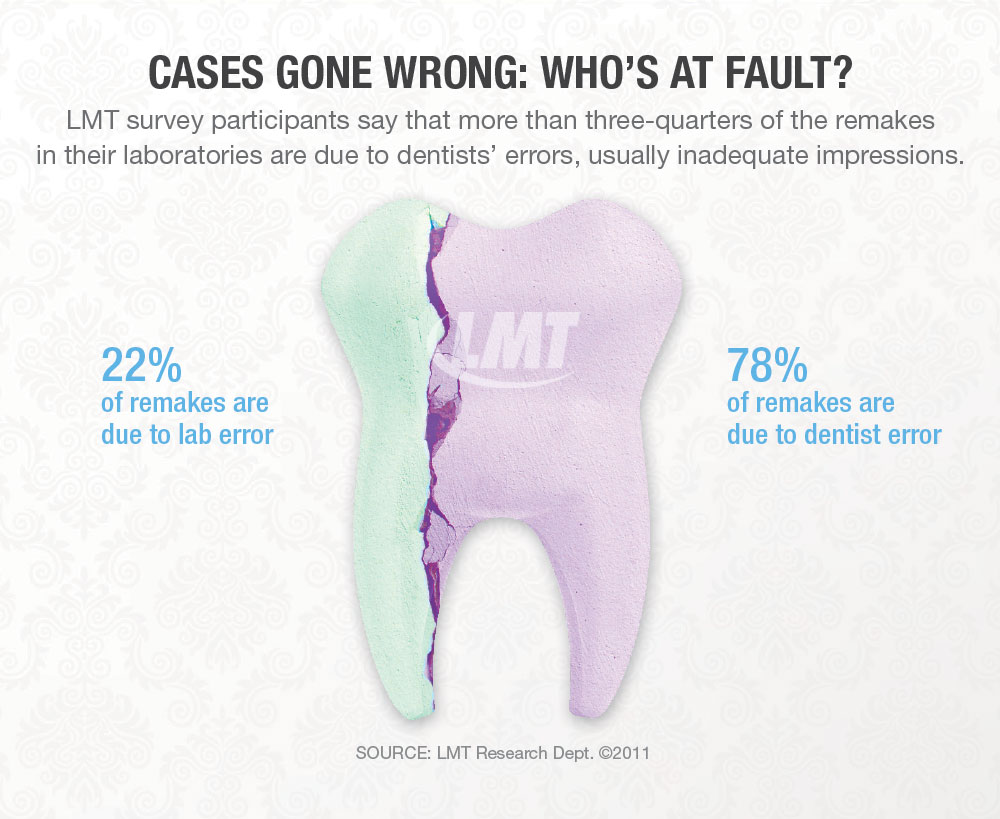

Add to that the frustration expressed by technicians who feel the bulk of remakes are beyond their control; in fact, Lab Management Today (LMT) survey participants say more than three-quarters of remakes in their laboratories are due to dentist error. These laboratory owners and managers repeatedly say that — across all departments — most remakes can be traced back to an inadequate impression.

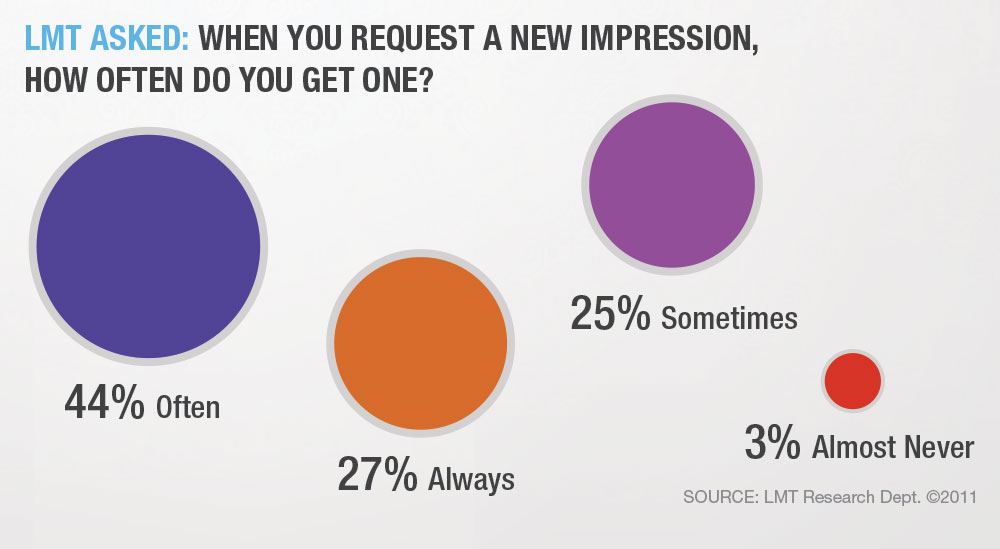

Of course, the quality of the final impression is dependent on a number of variables, but what’s equally important is how cooperative the doctor is when problems are brought to his attention. While most of LMT’s survey respondents say dentists appreciate a call about inadequate impressions, they are divided on the most common outcome: 41% say the dentist generally sends a new impression and another 41% are usually told to “do the best they can.”

To drive the point home and document potential problems, many laboratory owners are taking advantage of digital communication, saying a picture is worth a thousand words. “Providing dentists with photos of inadequate impressions enhances communication and eliminates the blame game,” says Jessica Birrell, CDT, Owner, Capture Dental Arts, Saratoga Springs, Utah, who annotates digital photos with captions and arrows using Photoshop software and emails them to the dentist. “Sometimes, I’ll also pour a stone model and send photos of that to point out specific problems. If the doctor still wants me to go ahead and guess at margin placement, I let him know I cannot guarantee the success of the case.”

No One-Size-Fits-All Policy

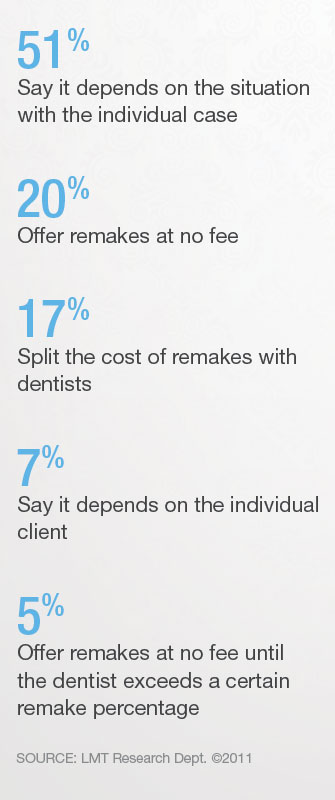

More than half of all laboratories don’t have a defined remake policy, saying that it depends on the specific case and sometimes on the specific dentist-client. “When a case is returned, we have to determine the reason and handle it accordingly,” says Ross Gaiteri, Owner, Benchmark Castings Inc., Columbus, Ohio. “If the lab is at fault, there’s no charge. If the fault clearly rests with the dentist, we charge 50%. However, if the dentist is repeatedly at fault for remakes — or we’re told to proceed when we call with concerns about his impression or model — we charge him full price.”

In an effort to eliminate the blame game altogether, 17% of participants routinely split the cost of remakes and one quarter of them don’t charge at all for remakes, at least until a certain remake percentage is exceeded.

To charge or not to charge is an issue that often divides laboratory owners. Some say laboratories shouldn’t routinely accept blame for cases that fail through no fault of their own. “If you don’t enforce a remake charge, it gives the dentist the impression that he can send you an inadequate impression or preparation at no risk to himself and, therefore, there’s no incentive to do a better prep or impression,” says Marc Posen, CDT, Owner, Posen Dental Laboratory, Birmingham, Michigan.

On the other side are laboratory owners who perceive free remakes as one of the value-added benefits they offer their customers. In most cases, they say, the cost of doing the remake is negligible given the value of a good account. “I have only a few clients and very low remakes, so my philosophy is that doing the remakes at no charge is part of the service I’m offering them,” says Paul Francoeur, Owner, Rogue Dental Solutions Inc., Ormond Beach, Florida. “When we do have that rare problem with a case, we communicate and work together to solve it, and they appreciate that I will take care of remaking it.” Of course, this approach requires laboratories to carefully monitor clients’ remake percentages and immediately address any issues.

The bottom line: whether you have a defined policy or not, keeping an eye on your clients’ individual remake factors and having honest conversations with them when things go awry is your best bet. “We know our mistakes cost dentists chairtime, just as their mistakes cost us labor, materials and transportation costs. But we’re making a custom product for sometimes challenging, difficult patients and the partnership requires both parties to be reasonable in their expectations,” says Jim Thacker, Vice President, Utah Valley Dental Lab, Provo, Utah. “A flexible, relationship-driven approach builds trust and value for both the laboratory and dentist.”

We’re making a custom product for sometimes challenging, difficult patients and the partnership requires both parties to be reasonable in their expectations. — Jim Thacker, Utah Valley Dental Lab, Provo, Utah

A Look at Laboratory Remake Policies

More than half of the laboratory owners and managers participating in LMT’s Remake Survey say they don’t have a defined remake policy. Here’s a closer look at how respondents handle those cases gone wrong:

The Impact of New Technology

Is the proliferation of digital technology having an impact on the industry’s remake factor? One effect is clear: two-thirds of laboratories that receive digital impressions say they result in fewer remakes than do conventional impressions. “The software for these systems tends to ‘force’ dentists to provide accurate reduction, enabling us to fabricate more ideal restorations,” says Jim Thacker, Vice President, Utah Valley Dental Lab, Provo, Utah. “Models created from digital impression technology are extremely accurate and allow us to create more consistent, predictable restorations for our dentists.” Milling, too, has had a positive effect, although to a lesser extent. While the majority of participants — 67% — say it hasn’t changed their overall remake percentage one way or another, one quarter of laboratories say milling has caused their overall C&B remake percentage to decrease due to more accurate fits.

Maribeth Marsico is the Senior Editor at LMT magazine, where she has been covering the dental laboratory industry for more than 20 years. For more information, visit lmtmag.com.

Reprinted with permission from LMT, March 2011. ©2011.