Dental CE

- Free online CE course by Justin Chi, DDS, CDT: “Clinical Success with CAD/CAM Restorations”

- Free online CE course by Carrie Webber: “New Technology: Disruption or Increased Production?”

- Free online CE course by Brad McKeiver, CPA, MBA: “The Right Time to Buy Dental Equipment: Debunking Tax Myths”

Related Dental Articles

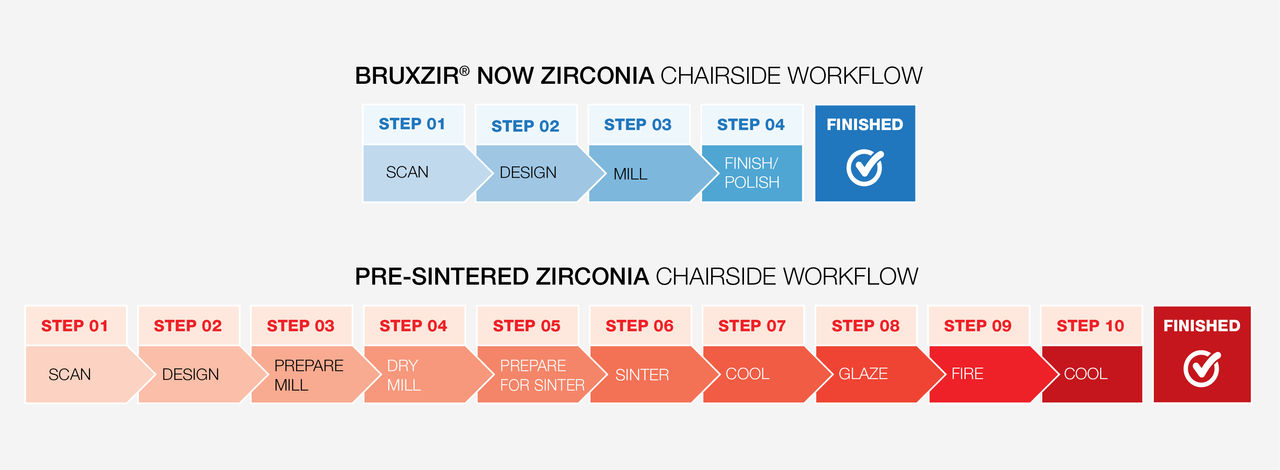

- Eric Relyea: “5 Common Questions About Chairside CAD/CAM Systems”

- “Fulfilling the Promise of Single-Visit Dentistry with the glidewell.io™ In-Office Solution”

- Michael D. Buck, DDS: “My First 60 Days: A glidewell.io™ Practice Report”

Dental Videos

- “Your Lab, Chairside: Single-Visit Dentistry with the glidewell.io™ In-Office Solution”

- “The glidewell.io™ Difference: Part 1 — BruxZir® NOW”

- “The glidewell.io™ Difference: Part 2 — CrownAI™”

- “The glidewell.io™ Difference: Part 3 — Vertical Integration”

In-Person Dental CE Course

- Justin Chi, DDS, CDT: “Hands-On Introduction to Single-Visit Dentistry with CAD/CAM Technology”