Product Spotlight: Obsidian® Fused to Metal

Porcelain fused to metal has been a popular restorative choice for over a half-century because of its combination of strength and esthetics. However, the fabrication methods typically employed in its construction — i.e., the casting of metal substructures and layering feldspathic porcelain — produce restorations that are prone to fracture. While today there are well-proven monolithic options available, several clinical situations are still indications for bilayer restorations, including bridge cases that lack the vertical height necessary for adequate all-ceramic connectors; cases where the restoration must match proximal PFMs; and areas with crown or root staining that would show through translucent restorations.

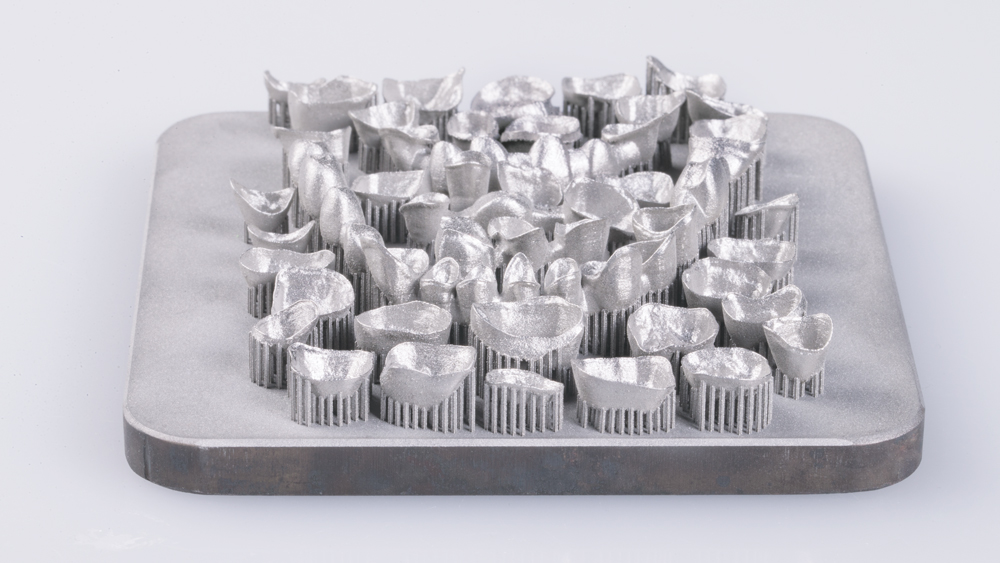

A batch of crown copings and bridge frameworks 3D printed onto a metal base plate

Obsidian® Fused to Metal crowns and bridges eliminate many of the issues experienced with conventional PFMs. In place of cast-metal substructures, Obsidian Fused to Metal restorations use copings created through selective laser sintering, a form of 3D printing. In this additive manufacturing technique, the understructure is designed digitally by a dental technician and then a computer-controlled laser replicates the desired shape layer by layer by fusing metal particles together. The resulting substructures achieve marginal accuracy of 20 microns, a significant reduction compared to the 50-micron margins found on cast-metal PFMs. Benefits of this process include minimizing the potential for marginal leakage and cement washout in the final restoration, and reducing the resultant gingival inflammation and discoloration.

Try-in of a 3-unit bridge framework that was made via laser sintering.

The advantages of Obsidian Fused to Metal restorations don’t stop at the enhanced understructure. The Obsidian lithium silicate ceramic utilized for these modern bilayer restorations is more than four times stronger and two times as chip resistant as the feldspathic porcelain employed in conventional PFMs.1 This upgraded durability reduces the chance of fractures and chips in the veneering layer, increasing the overall longevity of the restoration. The ceramic also exhibits a natural-looking appearance, with translucency that matches that of enamel and dentin.

Part 3D printed coping, part cutting-edge ceramic, Obsidian Fused to Metal restorations offer a solution for many clinical needs due to to their lifelike esthetics, improved strength and ability to block out discolored preparations. What’s more, they are delivered following conventional PFM cementation protocol, meaning that clinicians aren’t required to change existing workflows.

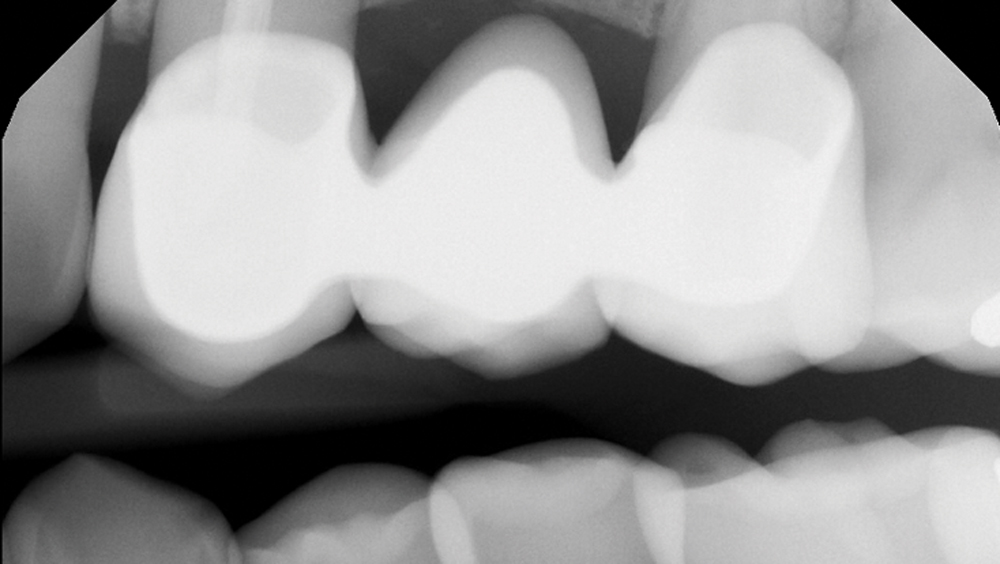

PREOPERATIVE CONDITION

DURING TREATMENT

FINAL OBSIDIAN PRESSED TO METAL BRIDGE

Dr. Anamaria Muresan’s patient had an existing PFM bridge on #11–13 with open margins and poor esthetics. Dr. Muresan removed the bridge, cleaned the preparations and adjusted the finish line apically, later delivering the Obsidian Fused to Metal bridge. The enhanced marginal integrity and ability to block out the underlying preparation resulted in a natural-looking appearance with reduced chance of marginal complications.

– Clinical dentistry by Anamaria Muresan, DMD, ME, CDT

References

- ^ Glidewell Laboratories Research & Development department, 18651 Von Karman Ave., Irvine, CA 92612