2201 Dupont Dr., Irvine, CA 92612

© 2020-2026 Glidewell. All rights reserved.

800-854-7256 USA

A look at how the technology of Glidewell Intelligent Manufacturing benefits clinicians

Some dental laboratories set the rules for you. They mandate what type of impression you can send them. They restrict your choice of intraoral scanner. And they tell you that it’s for the benefit of uniformity and convenience. In reality, it’s convenient for the lab, not for you. Glidewell takes a different approach.

From impression to delivery, Glidewell Intelligent Manufacturing — a proprietary suite of advanced digital technologies — ensures that simplicity, quality, speed and predictability work in the favor of the dentist. With Glidewell, dentists are free to submit either physical or digital impressions, and they can use whatever intraoral scanner they want. Glidewell makes this possible through its investment in and implementation of state-of-the-art automated manufacturing systems that utilize revolutionary technology, artificial intelligence (AI) and software programs.

The Glidewell Intelligent Manufacturing workflow consists of three steps: digital or physical impression intake, AI design tools, and a hands-free operation.

Cases can come to Glidewell Intelligent Manufacturing digitally or physically. The majority of cases are submitted digitally from clinicians’ intraoral scanners and are directly routed through to step two. Although there are a smaller number of cases still being submitted physically, Glidewell believes in meeting dentists where they are by providing a path forward for conventional impressions. Some dental labs focus on one submission type due to limited workflows or facility limitations. Glidewell prioritizes the dentist, ensuring every case can be processed.

For physical cases, micro CT impression scanning digitizes the elastomeric impressions to eliminate errors introduced by traditional plaster models and provide for a faster, more accurate means of crown fabrication.

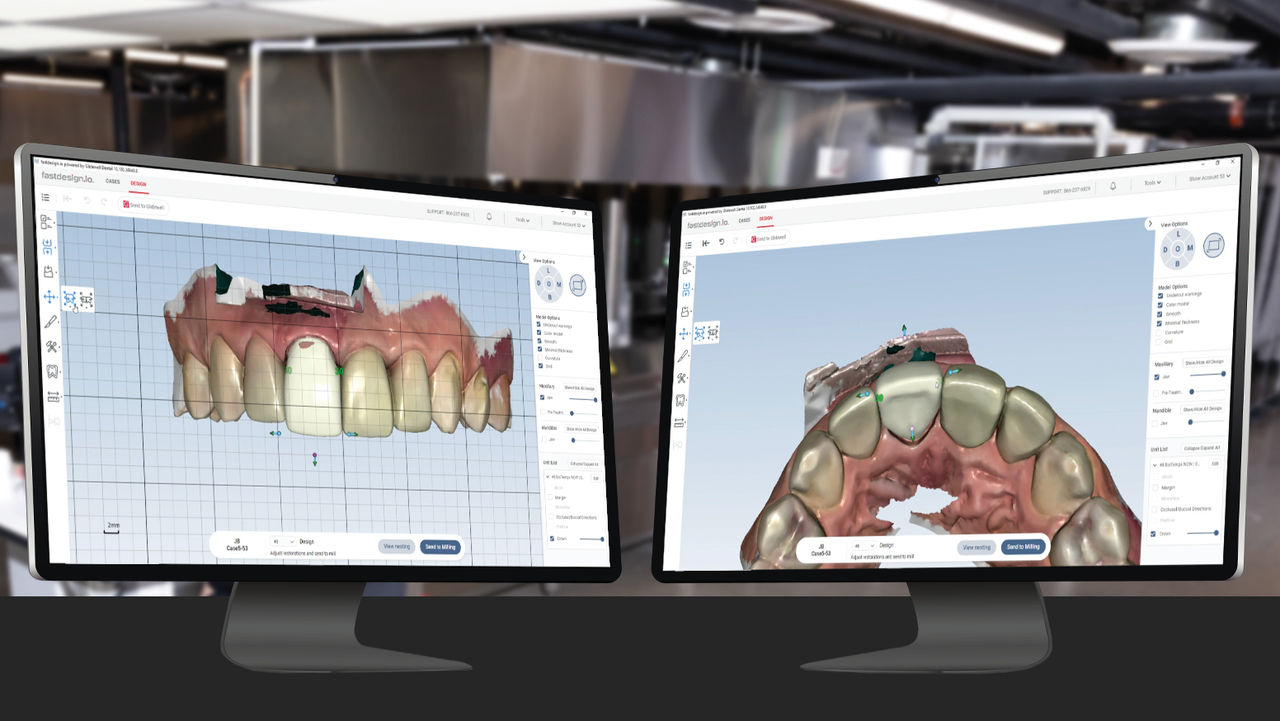

In a completely digital restorative process, digital impressions from the dentist bypass a proprietary workflow called the Virtual Plaster Experience (VPX) — a software for physical impressions that produces a three-dimensional image of a patient model based on the digitized impression file and enables die trim and margin marking operations to be performed digitally. Digital cases also bypass the technician who transfers those files from software to software. In this completely digital process, the software is integrated and seamless, removing the technician and allowing for the ultimate combination of precision and speed. This automated design service offers AI assistance with meshing, cleanup, articulation, margin marking, reductions and restorative proposals.

With Glidewell Intelligent Manufacturing, initial restoration designs are automatically proposed by proprietary software that makes use of machine-learning algorithms and takes into account the morphology of the patient’s surrounding dentition. From there, a technician can quickly accept or modify the design as needed, further “teaching” the software along the way.

In a conventional restorative process, incoming physical impressions are used to produce plaster models. Once they are converted to digital files, the plaster model process takes place in a virtual environment. Lab operators can then zoom in for a more precise view at any angle, and “undo” any errors without having to start over with the original impression and a new stone model. The design process for physical impressions also relies on the technician to craft the features required to make that restoration unique. The process is time-consuming and can be subject to significant variation from one case to the next.

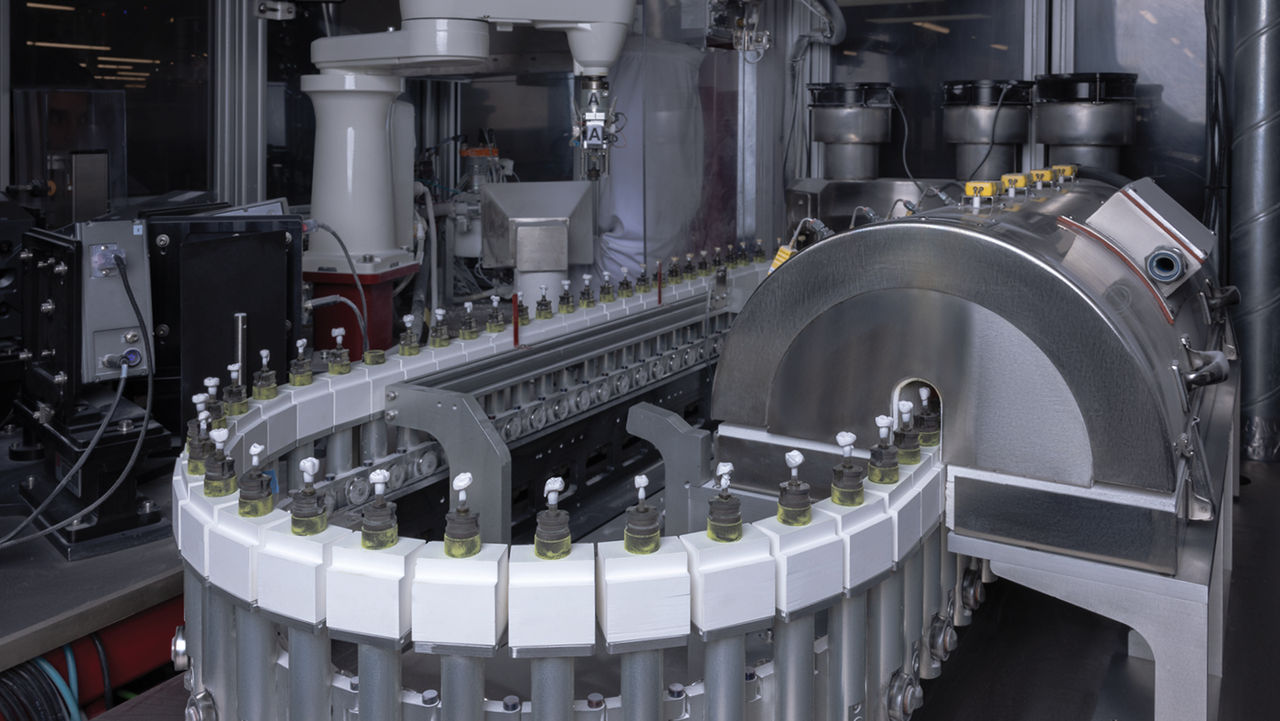

The Glidewell Intelligent Manufacturing production center is designed to fabricate patient-specific restorations at scale with unprecedented precision and consistency. This Industry 4.0 assembly is in essence a “smart factory” of the future that serves to minimize the inherent variability of human interaction with its nearly hands-free operation, while offering levels of efficiency and visibility never before seen in the dental industry. Enhanced technology like simulations and digital twins further pushes the boundaries of what was previously thought possible for augmented production lines. At Glidewell, it comes standard.

The complexity and thoroughness of the Glidewell Intelligent Manufacturing system brings simplicity to dental practices.

Doctors shouldn’t have to miss out on the benefits of a digital manufacturing process, even if they send physical impressions. That’s why the Glidewell Intelligent Manufacturing process begins by digitizing every case. Analog dentists are not required to invest in intraoral scanners, CT scanners, software or machinery — Glidewell Intelligent Manufacturing takes on that responsibility for them.

Simplicity is also apparent in the choices Glidewell Intelligent Manufacturing gives dentists who are submitting impressions digitally. Glidewell software enables clinicians to decide whether they want to design the restoration themselves, send their impression to the lab for a technician to design, or have AI design and mill the restoration. These options give the clinician the power to decide what’s right for that particular case, patient, or schedule.

AI also contributes to the quality of the final restoration. Whether it’s AI-guided designs, robotic milling, or vision tracking, cases that pass through Glidewell Intelligent Manufacturing undergo rigorous quality control.

While Glidewell has a long history of detailed quality control processes since its inception in 1970, the company began its development of a more modern, data-driven infrastructure in 2015. Machine-learning engineers, data scientists, software developers, CAD/CAM specialists, and even leading experts from the University of California Berkeley all contributed to making Glidewell Intelligent Manufacturing a technology-driven assembly line for high-quality restorative solutions.

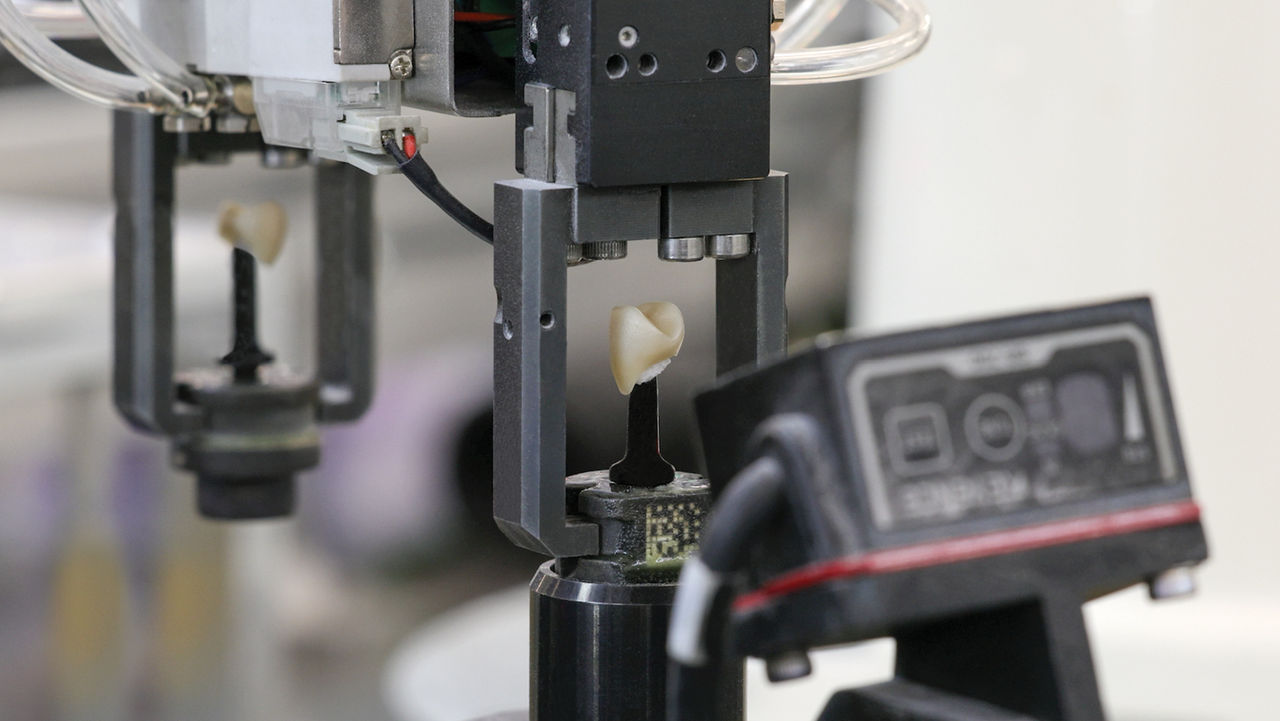

Today, quality is further verified by robotic milling machines and barcode and vision tracking on milling towers orchestrated by CloudPoint® on the Amazon Web Services (AWS) cloud. Optical inspections then compare the milled units to the design files, only accepting cases that meet a ≤50 µm tolerance (most cases achieve a 20 µm tolerance). This accuracy drives high-quality results, leading to fewer remakes and reduced chair time for dentists.

With Glidewell Intelligent Manufacturing, dentists can also receive these restorations in record time, allowing for emergency restorative work and schedule changes in the operatory. A three-day in-lab turnaround time is standard for 90% of crown & bridge cases in the Glidewell Intelligent Manufacturing workflow. With a 24-hour production cycle of both lab technicians and robots, Glidewell has made speed a standard service for dentists.

Rush turnaround times are also available, including Next-Day BruxZir®, which has the case back to the dentist in less than 21 hours. Dentists merely submit their digital case before 2 p.m. and the final BruxZir Zirconia restoration will be delivered the next morning by 10:30 a.m. This type of speed can dramatically improve dentists’ scheduling, enabling them to see more patients and boost revenue. It’s also a motivating marketing tool, attracting patients looking for a new practice.

The speed, quality and simplicity of restorative outcomes from Glidewell Intelligent Manufacturing offer predictability to dentists. The combination of advanced technology and large-scale infrastructure makes Glidewell a reliable lab with consistent results. Predictability promotes ease of mind — one less thing dentists have to think about during their busy schedules. With lower remakes and fewer chairside adjustments, dentists can focus on seeing more patients, growing their practice, and boosting revenue.

The predictability Glidewell Intelligent Manufacturing offers isn’t just a benefit to the day-to-day activities of a dental practice: It also can be used to plot the course of future growth in that practice. From a business standpoint, a lab with consistently reliable simplicity, speed, and quality — in addition to affordable pricing — frees up practice owners to think about expansion or other areas of growth they may have otherwise neglected.

Glidewell Intelligent Manufacturing redefines what dentists should expect from their dental lab. By combining cutting-edge AI, robotics, and open workflows, Glidewell Intelligent Manufacturing delivers restorations that are not only fast and precise but are also tailored to the realities of the modern dental practice. Dentists gain more control, with fewer limitations and greater confidence in every case — whether their workflow is digital or analog. In a landscape where labs often impose constraints, Glidewell empowers clinicians with simplicity, quality, speed, and predictability from impression to delivery.

To get started on a case with Glidewell or learn more, visit glidewell.com.

Blog Posts

Send blog-related questions and suggestions to hello@glidewell.com.