2201 Dupont Dr., Irvine, CA 92612

© 2020-2026 Glidewell. All rights reserved.

800-854-7256 USA

A look at the unique production challenges in dentistry and how Glidewell is using innovation to make the lab experience faster and more reliable.

In the world of manufacturing, mass production conjures images of assembly lines churning out identical widgets in a limited range of shapes and sizes, where uniformity is the goal and inventory is stockpiled in warehouses or storerooms until ordered by consumers at a later date.

Dentistry poses an altogether different challenge, with a far more complex set of requirements.

Every dental restoration, from crowns and bridges to dentures to occlusal appliances, is a one-of-a-kind creation, tailored to the unique geometry of a patient’s mouth. Nor can these products sit for months in a stockroom. Orders are taken and delivered on demand, as quickly as possible, driven by real-time patient needs.

At Glidewell, widely acknowledged as America’s leading dental laboratory, this ask is multiplied by tens of thousands of cases — more than 100,000 units — every week. That’s well over five million units per year. This degree of mass customization, unprecedented in virtually any other industry, requires a unique blend of precision, speed, and consistency — qualities that traditional, manual processes struggle to achieve at scale.

Since opening his doors in 1970, company founder Jim Glidewell, CDT, has worked to standardize processes and advance technologies in a way that would help satisfy these challenges, providing the efficiency and reliability that dentists demand. Today, he employs a small army of specialized engineers that is further addressing these issues with groundbreaking automation.

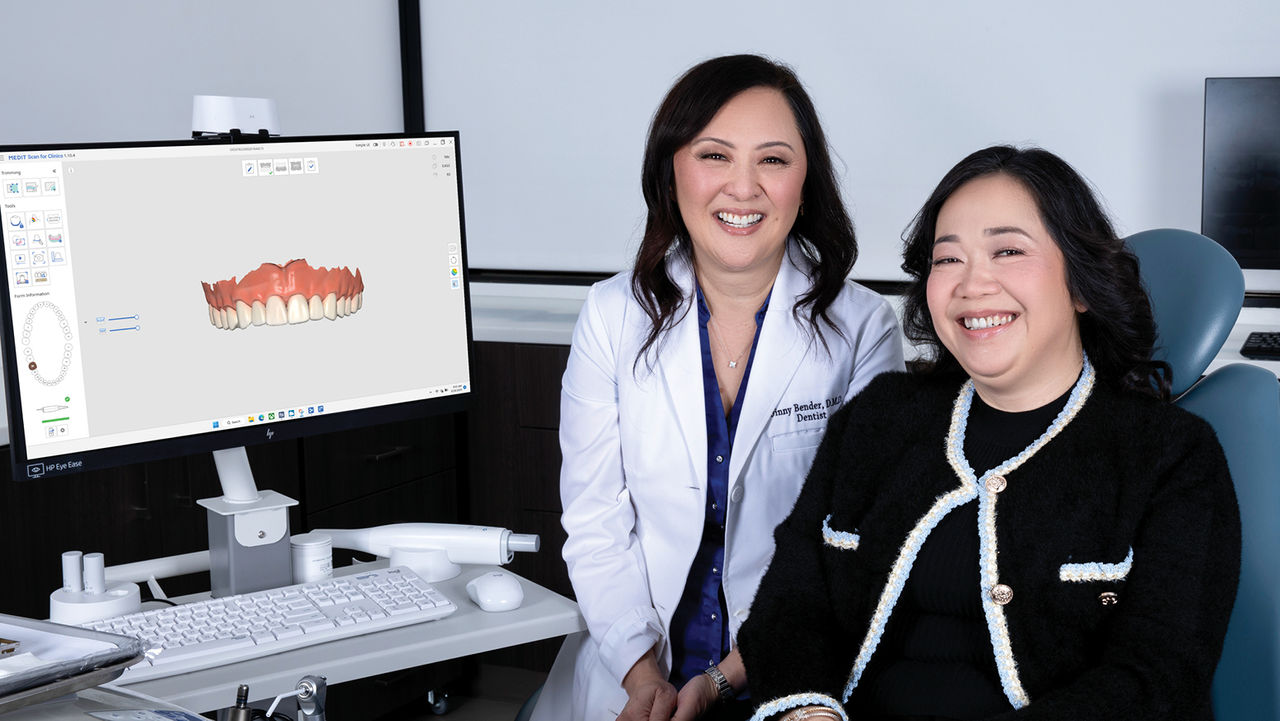

In a recent interview, James Zamora, vice president of engineering, and Alonso Delgado, senior manager of mechanical engineering, provided an in-depth look at how Glidewell is pioneering automation for mass customization. Their insights reveal not just the technical feats behind Glidewell’s operations, but also the profound benefits for dentists: faster turnaround times, predictable results, and significant cost savings.

As Zamora and Delgado illustrate, Glidewell’s commitment to vertical integration, digital technology, and relentless iteration is transforming how dental labs operate, ultimately empowering dentists to treat more patients and grow their practices.

Dentistry’s core challenge lies in its inherent variability. Unlike mass-produced consumer goods, dental restorations must fit the patient’s specific dentition or an “amorphous geometry” shaped by a dentist’s hand-prepped tooth. “Like snowflakes, no two are exactly alike,” Zamora explains.

Traditional labs rely on technicians of varying skill and experience to craft each piece, but human factors introduce inconsistencies. Different technicians might interpret the same crown differently, and even the same technician is liable to vary in his or her work, which is subject to variable factors such as lighting or fatigue.

This subjectivity extends throughout the production process — especially when looking at traditional analog workflows. Physical impressions can distort during shipping or handling, with the use of traditional stone models introducing even more opportunity for error. And final fits are often judged by feel in the dentist’s office. One dentist might deem a restoration perfect, while another finds it too tight or loose.

Either way, true fit isn’t ascertained until the restoration is tried in the patient’s mouth. If, at that point, it doesn’t fit just right, the dentist must spend valuable chair time adjusting it by hand, or send it back to the lab for a remake, rebooking the patient for a later appointment. Either outcome is generally deemed a failure, disappointing to all involved.

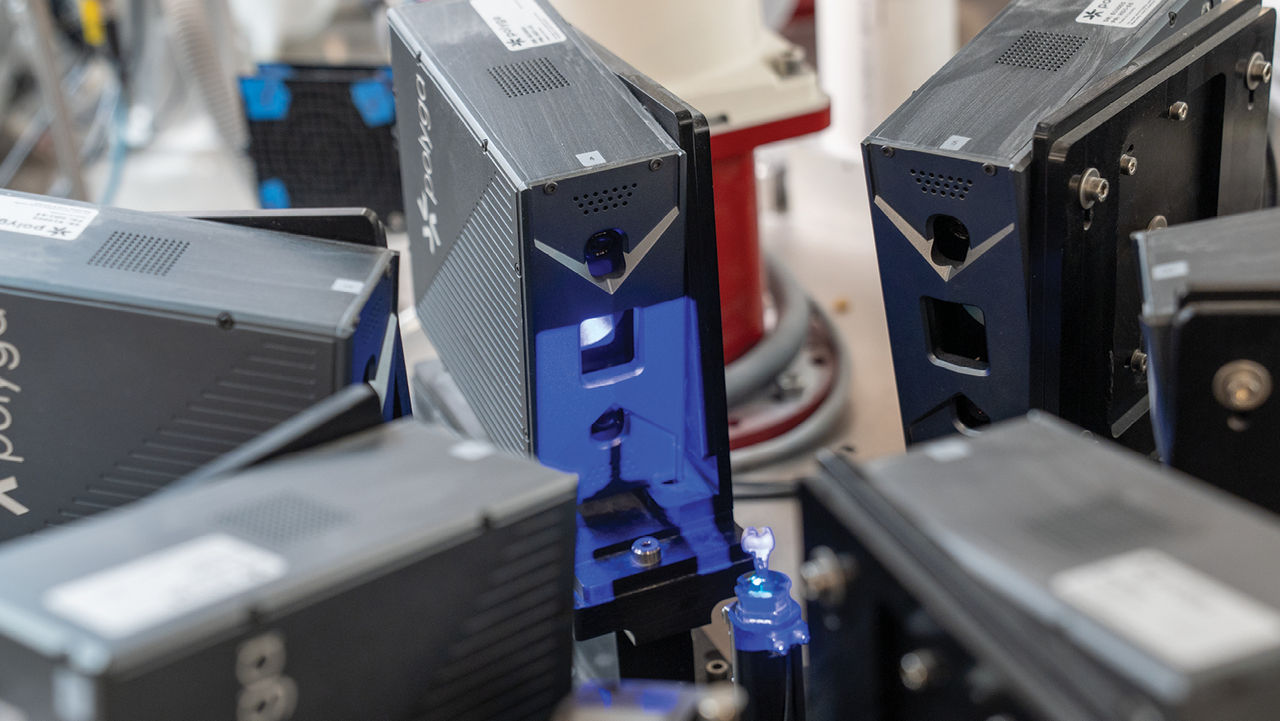

CT impression scanning by Glidewell helps to eliminate conventional plaster room errors. And intraoral scanners serve to bypass physical impressions altogether. But even scanners provide some degree of variability, depending on model, software algorithms, and scanning technique.

Add to this the need for traceability to avoid mix-ups when producing and handling thousands of units per day, and it becomes clear as to why automation can present significant advantages to manual processing.

Of course, most dental labs lack the volume to justify upfront automation investments. Equipment, materials, labor, and expertise come at a steep price. But with Glidewell’s massive scale, the math changes. Automation becomes a necessity to eliminate variability, ensure repeatability, and meet the just-in-time demands of modern dentistry.

Glidewell’s undeniable advantage is vertical integration: developing everything internally rather than outsourcing. This approach stems from the realization that dentistry’s processes are too specialized for generic solutions.

“To employ outside engineering firms at Glidewell would be extremely challenging due to the unique way in which our restorations are made,” Zamora says. Hiring and training external contractors would mean endless iterations and high costs, with slower development times and little guarantee of success.

Instead, Glidewell invests in an in-house engineering team, including mechanical engineers, programmers, construction crews, and service technicians. This allows for rapid prototyping, testing, and deployment, among specialists who have become intimately familiar with the unique challenges dentists face.

When Zamora was recruited by Glidewell fourteen years ago, he was initially skeptical. “What could I possibly do at a dental lab?” But a tour of the facility revealed the near limitless potential for groundbreaking engineering achievements, making more use than he might have expected of his high-tech background in building custom machinery for medical devices and pharmaceuticals.

Delgado, drawing from his experience in semiconductors and bottling sectors when joining Glidewell twelve years ago, similarly noted that automation often boils down to rearranging the same components — motors, bearings, electrical parts — in new and interesting ways. “As engineers, we’re more or less all playing with the same LEGO parts,” Delgado said. “So it’s more about understanding the unique application.”

This in-house model gives Glidewell the flexibility to adapt proven technologies to dentistry’s specific needs, creating and iterating systems that no off-the-shelf solution could match.

It also yields significant returns on investment (ROI), by which Glidewell maintains its reputation as an affordable provider of custom dental solutions, and invests in the next generation of technology. Automation projects often pay for themselves far faster than in other, more standardized industries. Zamora recalled his first Glidewell project — a machine for gluing zirconia material blocks to milling mandrels — that recouped its investment in mere weeks.

By calculating non-recurring engineering costs upfront and targeting 18-month paybacks, Glidewell justifies bold investments. The upfront spend buys “time compression,” as Jim Glidewell puts it: shorter development cycles, faster maintenance, and overall uptime that minimizes the wait for dentists and their patients.

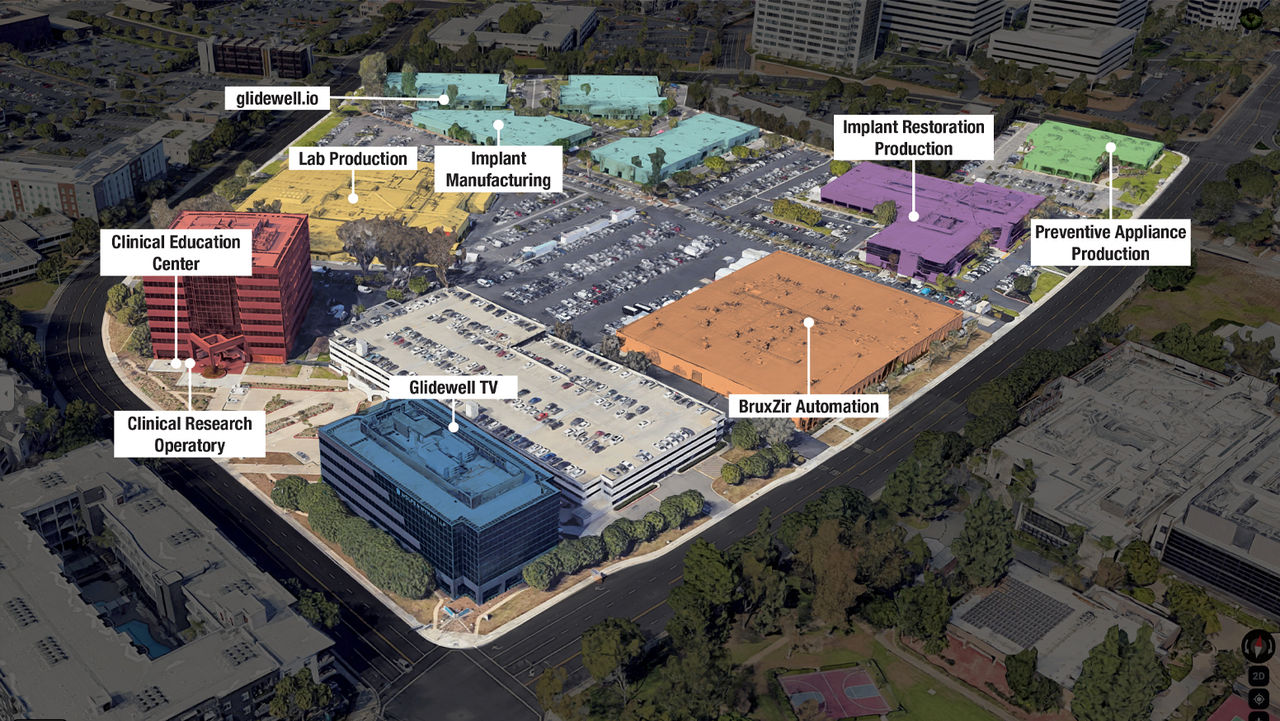

The sheer scale of Glidewell operations typically leave visitors to the sprawling campus in Irvine, California, speechless. Because the accumulation of custom-built technology, and the relentless pace of ongoing research and development, is unlike anything to be found elsewhere in dentistry.

Nowhere is Glidewell’s proprietary automation technology more evident than the company’s Intelligent Manufacturing center. Lovingly referred to as “BruxZir Factory,” these dual, parallel automation lines produce BruxZir® Zirconia restorations — the “bread and butter” of restorative dentistry — with minimal human intervention, boasting tighter tolerances and more predictable outcomes than ever before.

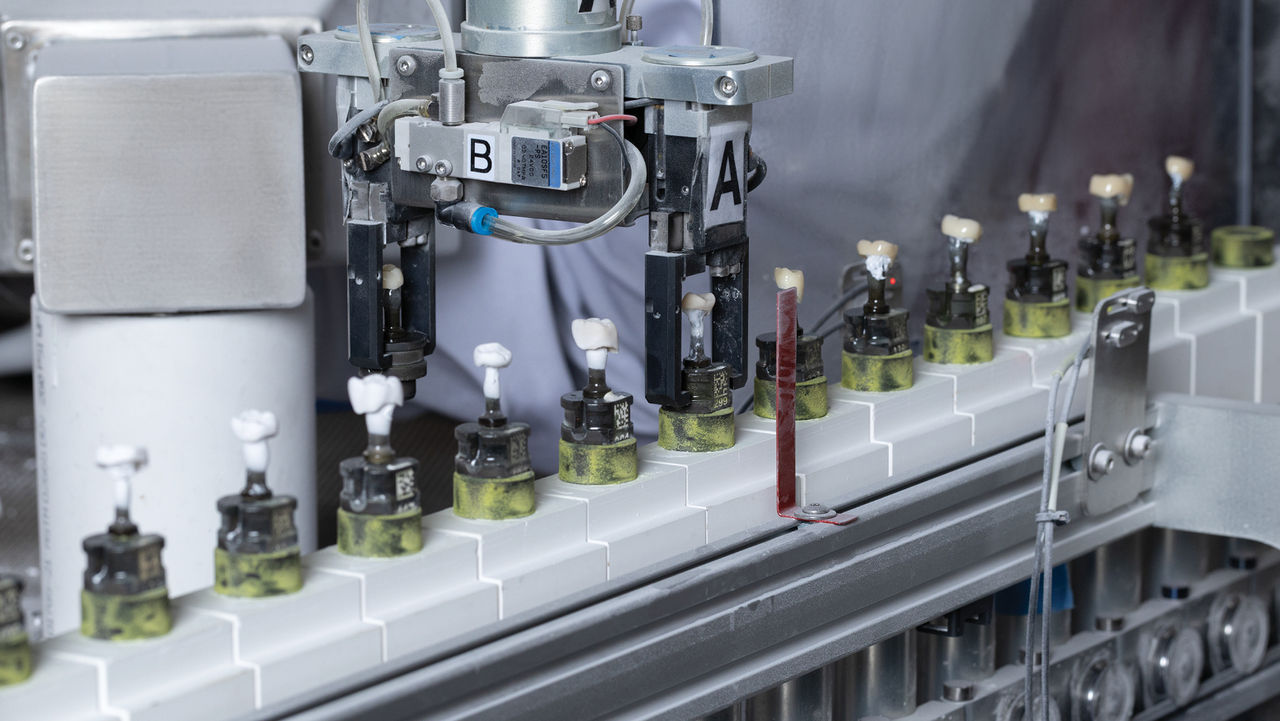

The BruxZir Factory workflow begins with a block dispenser, in which operators load drawers with foam trays of zirconia blocks (BruxZir Full-Strength and BruxZir Esthetic formulations) in various base shades. Robots select a block based on case requirements, scanning a block-specific barcode not only for verification of material and shade, but to determine the specific enlargement factor (EF) derived from each block’s density. This ensures the system can mill to the correct size to account for precise material shrinkage during the downstream sintering process.

Once the appropriate material block has been selected, a robot loads it into one of the available milling machines. Each mill is equipped with three spindles with varying tool diameters for roughing, finishing, and detailing the crown. An innovative retention process mills one side of the crown before rotating 90 degrees and filling the void with liquid wax. It then rotates another 90 degrees, and mills the other side of the crown while the wax holds it in place. This wax fixture process serves to eliminating the need for mechanical sprues, which would historically require removal and post-polish by hand.

After milling, robots transfer the units to perforated, multi-slot trays with unique QR codes for continued traceability. A conveyor transports these trays through a de-wax station that uses hot water showers to melt the wax from the restorations. Mechanical fingers remove the remains of the original holders, and deposits them into an underlying recycle bin once the tray has moved on. A continuous oven serves to burn off any remaining wax residue, before an array of cooling fans prepares crowns for handling at a human quality control checkpoint.

At this stage, trained operators are today inspecting the restorations for any milling errors, then applying specific shading recipes to each crown in a process known as pre-coloring. Even here, however, technology is employed by way of machine vision systems that track the transfer of a crown from the de-wax tray to a sintering tray. These cameras serve to maintain chain of custody while monitoring each restoration’s movement.

Pre-colored crowns are transferred manually to an array of sintering ovens, where the zirconia material undergoes a specific thermal cycle for final crystallization. From there, operators deliver the sintered restorations to an Auto Finisher.

The Auto Finisher first performs a dimensional QC analysis by scanning the physical crown and comparing it to the original design file and patient scan. An extensive 3D mapping process determines whether the restoration lies within a 50-micron tolerance of the design and scan. Anything outside that 50-micron tolerance — roughly half the width of a human hair — is rejected.

Those that pass are conveyed by robot to an automated glaze station in the Auto Finisher, which sprays a computer-prescribed layer of glaze over the crown, based on its geometry. The glaze is baked via passage through a continuous oven prior to moving downstream.

All of this is meticulously traced and tracked through software and analytics to monitor and optimize machine data to predict maintenance, shut down faulty components automatically, and optimize scheduling — preventing small issues from escalating. For example, if multiple units from the same mill are rejected one after another, the system will automatically remove that mill from the production queue for calibration or troubleshooting.

Manual processes like sandblasting the intaglio of the crown and visual QC persist, but automation is encroaching. Even in the shipping area, staging cubbies and an LED light system have been devised that allow for bundling multiple restorations per patient, and multiple patients per doctor, before packaging — reducing outbound shipping costs for the dentist. LED indicators signal complete jobs, and conveyors route the ready items to packaging.

Glidewell’s automation delivers transformative advantages. Production speed is unprecedented, with 87% of cases processed within 24 hours. In turn, with this new speed standard, Glidewell offers next-day delivery for BruxZir crowns and bridges upon request. This can drastically reduce the amount of time patients spend in temporaries and minimize the risk of extra appointments wasted on interim re-seatings.

For any dentist who has ever experienced the frustration of receiving the wrong case, Glidewell automation ensures traceability throughout its manufacturing process. Should a restoration become separated from its identified carrier, the unit is simply re-milled.

Predictable results stem from objectivity. When properly calibrated, machines don’t tire or vary, ensuring every BruxZir crown fits within extremely tight tolerances. And automation replaces the natural “bell-curve” range of technician quality with machine consistency. Remakes drop thanks to machine-driven QC technology, minimizing any need for chairside adjustment. Dentists no longer have to request “your best technician” as they might have once upon a time, because automation guarantees maximum consistency.

Financial savings are equally compelling. Automation slashes labor costs, enabling Glidewell to resist inflationary forces and maintain competitive pricing without sacrificing quality. Bundled shipments save dentists money on multi-unit or multi-patient orders.

Ultimately, these efficiencies help dentists ensure a smooth-running practice. With reliable, affordable restorations, practices can handle higher volumes, expand services, and focus on patient care rather than laboratory logistics.

For all of the company’s achievements, Glidewell refuses to rest on its laurels. The team pursues constant iteration, targeting bottlenecks like downstream staging and outbound processes in 2026. Meanwhile, active development continues behind the scenes on a host of new and emerging technologies that will continue to revolutionize restorative dental workflows in the lab and in the clinic.

By building custom software, hardware, and materials in-house, Glidewell maintains quality, agility, and service. “We’ve had to build all this stuff ourselves,” Zamora reiterated. This closed-loop approach — from input to output — promises a future where automation spans the entire workflow. Unlike companies focused on one or two products, Glidewell handles diverse applications: conveyors for shipping one month, zirconia pressure-casting machines the next, or newer mills and robotics for lab work. “As soon as we introduce one solution, the enterprise will come to us and say, ‘Now we need something else,’” Delgado shared. Because dentistry demands constant improvement.

As dentistry evolves, Glidewell’s engineers are ensuring the future is automated, efficient, and patient-centered. Because Glidewell’s use of automation for mass customization isn’t ultimately about the machines; it’s about redefining what’s possible in dentistry. By addressing variability, ensuring traceability, and delivering consistent quality at scale, Glidewell equips dentists with tools to succeed in a demanding field. The company’s longstanding iterative journey — from low-hanging fruit to high-impact innovations — drives ongoing value.

In an industry where precision meets personalization, Glidewell stands apart through vertical integration and a commitment to relentless improvement. Dentists benefit from faster, more reliable restorations, lower costs, and the freedom to practice as they choose. Patients get better outcomes, more quickly and conveniently. In the end, more patients receive care, and dental practices find it easier thrive, which is what truly drives Glidewell’s endless cycle of innovation.

Send blog-related questions and suggestions to hello@glidewell.com.