2201 Dupont Dr., Irvine, CA 92612

© 2020-2026 Glidewell. All rights reserved.

800-854-7256 USA

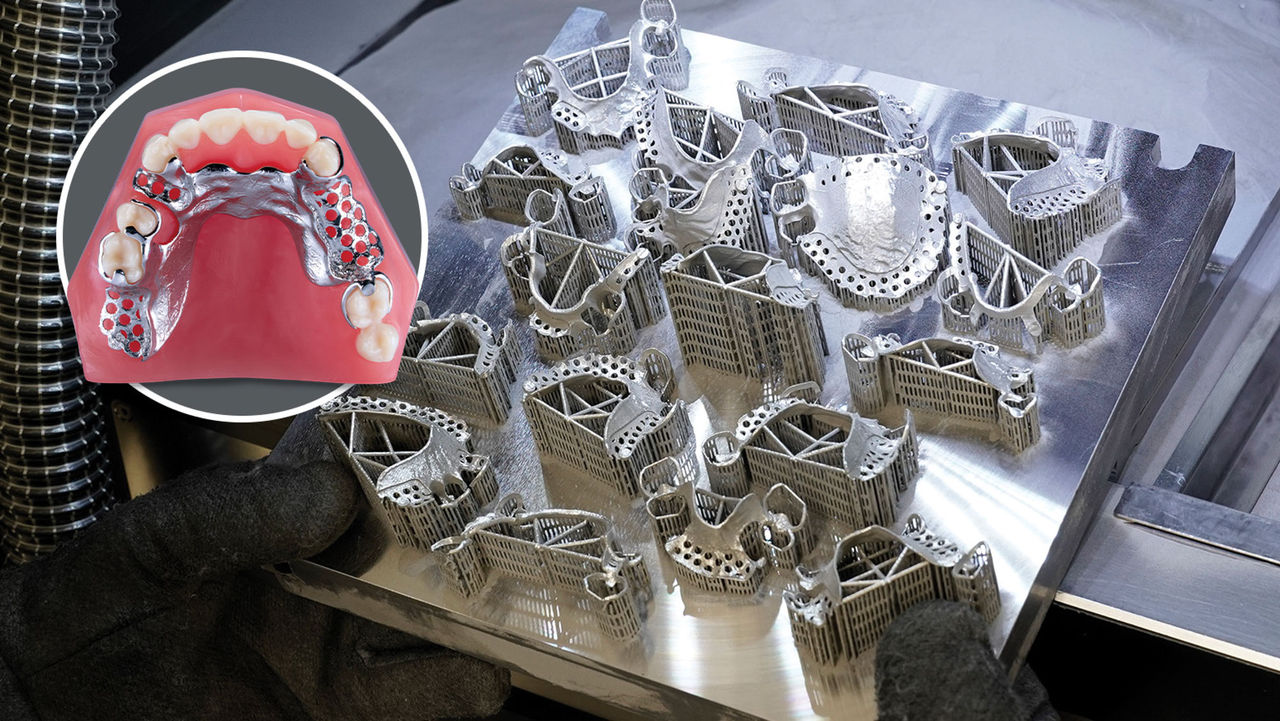

Discover how the selective laser melting process can enhance your metal partials.

SLM is an additive manufacturing technique that uses a high-powered laser to selectively fuse powdered metal layer by layer. In the dental world, this means cobalt-chrome frameworks for partial dentures can be created directly from a digital design file, bypassing the variability and labor intensity of wax-ups and investment casting.

The result? Frameworks that are not only incredibly precise but also stronger and more consistent than traditionally fabricated alternatives.

At Glidewell, SLM processes are seamlessly integrated into the digital workflow. From intraoral scanning or model digitization to CAD and SLM fabrication, every step is optimized for speed, accuracy, and repeatability. This ensures a better fit the first time, reducing chairside adjustments and remakes.

Glidewell pairs this advanced technology with a deep understanding of clinical expectations. Lab technicians collaborate closely with dentists to deliver frameworks that meet both esthetic and functional demands.

“By moving to SLM, we’ve drastically reduced variability in our metal partials and improved overall turnaround times,” said Steve Laguna, general manager of Glidewell’s Combo/Partials Department. “This process allows us to provide a stronger, better-fitting product with fewer adjustments needed at the chair. It’s a win for both the dentist and the patient.”

Each SLM-fabricated partial is carefully reviewed in the lab for fit, function, and esthetics before it ever reaches your operatory. Whether you’re treating a long-time denture wearer or a first-time partials patient, SLM-printed metal frameworks provide a level of confidence that both clinicians and patients can trust.

Visit glidewell.com/solutions/removable-prosthesis/partials to learn more or submit a case.

Related Dental Blog

Related Dental Article

Send blog-related questions and suggestions to hello@glidewell.com.