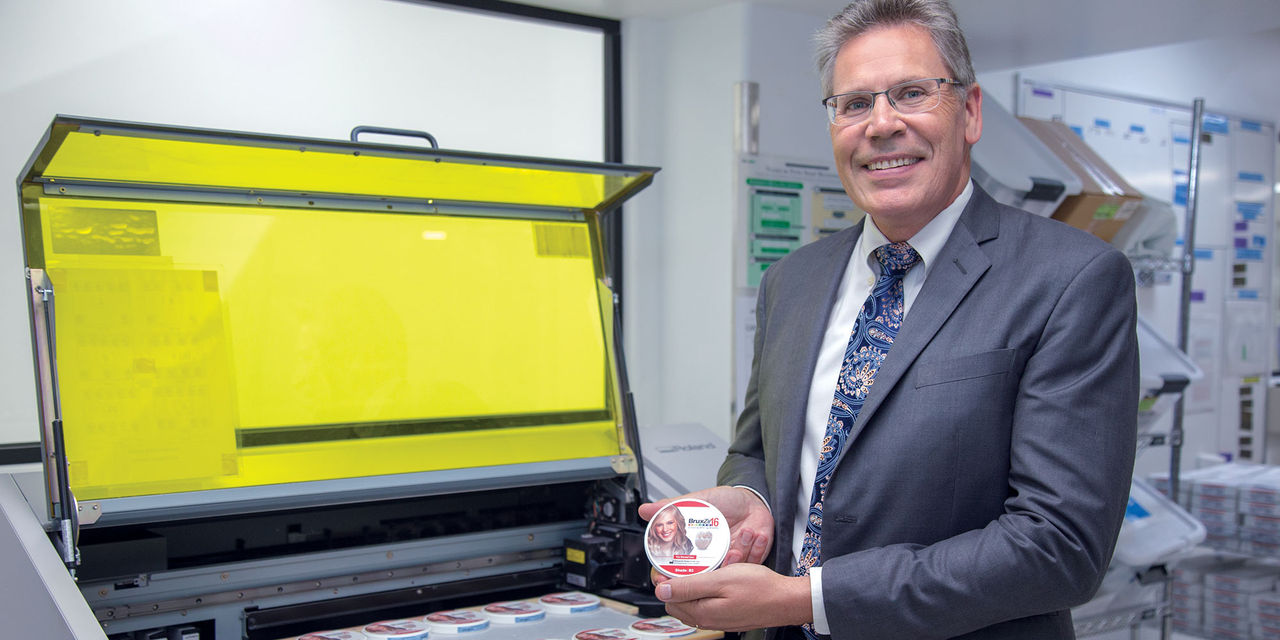

Employee Spotlight: Grant Bullis, Vice President and General Manager of Manufacturing

In 2007, Grant Bullis received a call from Greg Minzenmayer, his former coworker at Nobel Biocare and current chief operating officer at Glidewell Dental. After some catch-up conversation, Greg asked Grant if he was open to talking about a new job opportunity at Glidewell. The discussion piqued Grant’s interest. Greg wanted to bring the manufacturing of precision implant components to Glidewell, and Grant would be tasked with building the implant manufacturing division. It was both a challenge and an opportunity, and Grant decided he was up for it.

Since that day, Grant has spent the past 11 years working his way up in the business, from project manager and engineer, to director, and eventually to his current position: vice president and general manager of manufacturing. Since taking on his present role, he’s helped grow Glidewell into a respected and trusted manufacturing partner and industry leader.

Grant currently oversees manufacturing of a wide range of Glidewell Dental products, including Hahn™ Tapered Implants, Inclusive® Tapered Implants and prosthetic components, BruxZir® Solid Zirconia, Obsidian® lithium silicate ceramic, Camouflage® NanoHybrid Composite, injection molding equipment and materials, and the machinery involved in restoration and dental device fabrication. The leadership role Grant has taken with the company has been key in pushing Glidewell toward a bright future and furthering its mission to expand patient access to affordable, high-quality dental care.

CHAIRSIDE® MAGAZINE: Can you tell us a little about your background and how you got into the dental industry?

GRANT BULLIS: I’m originally from a farm in rural South Dakota, but for the past 34 years, I’ve called California home. In 1984, I was stationed here while I was in the Marine Corps. When I got out, I decided I was going to stay.

I got into the dental implant business in 1997 as an engineer and draftsman at a small dental implant startup called Steri-Oss. At the time, I knew nothing about implants but was interested in trying something new.

I was put under the direction of more senior engineers, who taught me everything about dental implants and prosthetics. Once I learned the ropes, I began by working on new implant designs, using what I had learned from previous implant systems for reference. It was a great place to gain experience, since it was a small, very innovative company.

CM: What brought you to Glidewell Dental?

GB: About a year after I began working at Steri-Oss, Nobel Biocare bought the company. I continued working there several more years with a lot of great people, one of whom was Greg Minzenmayer.

Although my background is in mechanical CAD/CAM technology, in 2007 I received my Master of Business Administration from the Keller Graduate School of Management. By that time, I had also left Nobel Biocare. Shortly thereafter, I received a call from Greg. He asked me if I was interested in joining the team. I was curious because the company was known for being a dental laboratory. From what I had heard, they weren’t even restoring implant cases. I didn’t know what Greg’s intentions were, but I decided to meet with him. After our discussion, I thought it over and decided to accept a position as a project manager and design engineer.

Grant Bullis inspects a new addition to the Inclusive line of prosthetic components with engineers at Prismatik Dentalcraft, Inc., the manufacturing arm of Glidewell Dental.

CM: What was the implant department like when you started, and how did you get the ball rolling?

GB:The implant department certainly did not exist as we know it today, because we didn’t have the same capabilities that we now have with CAD/CAM, direct 3D printing of metal structures, and automation. While implant manufacturing is a major part of our business at Glidewell today, back then we only had about three rows of benches in our production facility. I remember having a computer that had a difficult time running SOLIDWORKS® (Dassault Systèmes SolidWorks Corporation; Waltham, Mass.), a 3D CAD design software program, and having to borrow a pair of calipers from David Leeson, our current vice president of engineering. It was very much a startup type of situation.

I began designing compatible parts for the major implant systems and adapting them to our specific needs on the restorative side, as Glidewell Dental President and CEO Jim Glidewell, CDT, ultimately foresaw that implant therapy was going to become an essential part of dentistry. We would machine prosthetic components, evaluate the fit and function, and keep iterating until we were satisfied. I also met with some of my sources in the precision-machining industry and told them we were putting the band back together. They manufactured parts to our drawings, which helped us get started with both prosthetic components and producing implants of our own.

CM: How were you able to work with what was relatively limited technology at that time to build up the department?

GB: In 2007, dental laboratories were not milling titanium custom abutments, which we have always considered essential in simplifying the delivery of implant restorations. Because options were so limited, we decided to start looking at the process of making our own. The implant department joined with our digital manufacturing team, and we created an open system that would allow us to make custom abutments on our own terms. We integrated a scanner, a mill, and a CAM program into an open system. Although these machines were not specifically designed to work together, we figured it out and developed a solution.

Grant’s Educational and Professional Background

- Degree in mechanical CAD/CAM from Irvine Valley College

- Master of Business Administration from Keller Graduate School of Management

- Engineer and designer of dental implants and prosthetics for Steri-Oss and Nobel Biocare (1997–2005)

- Director of implant R&D and digital manufacturing at Glidewell Dental (2007–2014)

- Vice president and general manager of manufacturing at Glidewell Dental (2014–present)

CM: How has that situation changed over the past few years?

GB: Now, our information technology (IT) department has taken over the role of digital manufacturing. We write our own software, manufacture our own milling systems for use in the laboratory and in-office, and build our own machinery. Today, we have people in positions across R&D, engineering, manufacturing and restoration fabrication, which makes us integrated in almost everything that we do. Eleven years ago, that was not the case. From then to now, we’ve progressed to more automation and technology to do jobs that used to be done manually, resulting in superior precision and consistency. That means the parts — and the restoration — will fit better in the patient’s mouth.

CM: Were there any specific events that helped contribute to the growth of manufacturing capabilities at Glidewell Dental?

GB: In 2009, the economic recession hit and there was a glut of machinery available at attractive prices at the same time that we were growing rapidly. From 2009 to 2011, we were able to add high-precision lathes and mills, expand our capacity and extend the implant manufacturing facility.

And then we brought BruxZir Solid Zirconia to market. It couldn’t have happened at a better time. Adding our own full-contour zirconia line as CAD/CAM systems were opening up and high-tech machinery was readily available created the perfect storm. The strength and esthetics of monolithic BruxZir restorations gave our customers new treatment options like the BruxZir Full-Arch Implant Prosthesis — a vast improvement over the acrylic hybrid dentures that preceded it.

From there, it felt like things grew overnight. We developed the comprehensive line of Inclusive® Prosthetic Components (Glidewell Direct; Irvine, Calif.), which are compatible with most of the major implant platforms and allow for more predictable restorative costs through uniform pricing across systems. Along the way, we’ve introduced three implant systems of our own. Most recently, we worked with Dr. Jack Hahn, whom I’ve known since my days at Steri-Oss and Nobel Biocare, to develop the Hahn™ Tapered Implant (Glidewell Direct), which has been very well-received by dentists and is now the official implant system of the Misch International Implant Institute.

Dental Materials, Implants and Prosthetics Manufactured Under Grant’s Supervision

Since Grant took on his first leadership role at Glidewell Dental in 2007, he has helmed the development and manufacturing of a wide array of dental materials, implants and prosthetic components. The intent behind each is the same — to further the mission at Glidewell Dental to provide dentists with restorative products that help expand patient access to affordable, high-quality care.

Restorative Materials

BruxZir Solid Zirconia

Obsidian lithium silicate ceramic

Camouflage NanoHybrid Composite

Dental Implants

Inclusive Tapered Implant System

Inclusive Mini Implant System

Hahn Tapered Implant System

Restorative Solutions

Inclusive Custom Implant Abutments

Screw-Retained Implant Crowns

BruxZir Full-Arch Implant Prosthesis

Obsidian Fused to Metal

Inclusive Prosthetic Components

Healing AbutmentsImplant Analogs

Impression Copings

Multi-Unit Abutments

Scanning Abutments

Temporary Abutments

Titanium Abutments and Esthetic Abutments

UCLA Gold and Plastic Abutments

CM: Can you describe the product development process at Glidewell Dental?

GB: “Product development” is a good term for it. We’re looking for unmet needs and developing innovations that will make our restorations better. We are always striving to make things simpler, more convenient and more affordable through the design and manufacturing of materials and components that streamline dental technology. We have a very progressive environment, and we’re always looking to make something better than what is already out there.

The Hahn Tapered Implant is a great example of our product development in action. Working with Dr. Hahn, who is a true pioneer in dental implantology, to create an advanced solution was such a rewarding experience. Dr. Hahn has placed and restored tens of thousands of implants, and we were able to translate his experience into every aspect of the Hahn system.

CM: After working here for over a decade, what’s your favorite part of your job?

Grant on the production floor with Dr. Jack Hahn, whom he collaborated with in the development of the Hahn Tapered Implant System.

GB: We get to develop new products from beginning to end. I enjoy the creative process, and we have so many capabilities under one roof. The most rewarding thing about manufacturing at Glidewell is that we produce solutions that make a real difference in people’s lives. A block of zirconia might not look very impressive by itself, but from that we mill a crown or bridge for someone that’s going to last a very long time. The BruxZir Full-Arch Implant Prosthesis can make an enormous difference in the quality of a person’s life.

I still remember when we were just a small entity in manufacturing. Today, we’re continuing to progress and grow as a leader in dental technology. It’s a lot of fun to be involved in a thriving enterprise.

CM: What do the next 11 years look like for you?

GB: I know that whatever we do, we won’t stagnate. We will continue tightening our vertical integration with the customer and patient in mind, while growing and refreshing the industry with new materials, tools and techniques. There’s so many different developments coming out with AI, automation and continued advancements in materials, so I know the future is going to be very dynamic.

Since joining Glidewell Dental in 2007, Grant has overseen the development of and obtained FDA 510(k) clearances for a comprehensive array of dental implants and prosthetic components.

CM: What do you like to do when you’re outside of work?

GB: When I’m not at work, I like to spend time outdoors. I have a small cabin in the mountains and a boat, and I like to do long-distance running. I’ve always felt like it’s a good way to recharge and then get back to work. When I’m not in it all, I like to get away from it all.

CM: Thanks for speaking with us today — it seems like you’ve had a very exciting journey with the company!

GB: Thank you for having me. It’s definitely been great to be a part of all of it. I’m looking forward to continued growth and innovation!