Screw- or Cement-Retained Implant Restoration — or Both?

When placing and restoring implants, one of the most important decisions is whether to provide a screw- or cement-retained restoration. While dentists increasingly prefer screw retention as a means of simplifying crown delivery and avoiding problems related to residual cement at implant sites, both solutions offer distinct advantages and warrant consideration based on the clinical circumstances of each case.1,2,3

CEMENT-RETAINED RESTORATIONS

The primary benefit of cementable implant crowns is that they can be delivered over a custom abutment to correct for implant angulation. In situations that call for a cementable restoration, custom abutments are also beneficial because the margin of the abutment can be carefully positioned by the lab so that it resides at or just slightly below the gingival surface, easing the removal of excess cement. Further, custom abutments are designed to create the ideal “prep” needed for passive seating, a natural emergence profile, optimal crown retention and improved direction of loading forces. Another potential benefit of cementable crowns is the ideal occlusal anatomy resulting from the lack of a screw access hole in the middle of the occlusal table.

The primary disadvantage of cementable restorations is the potential for complications resulting from residual cement at the implant site, which, as mentioned above, can be minimized through the use of custom abutments. Another drawback is the difficulty of removing a cementable crown if access to the implant site is needed for prosthetic maintenance, especially if a permanent cement has been used. One other key consideration is that more interocclusal space is required to achieve the retentive abutment form and height needed for a cementable restoration.

Advantages of Cementable Crowns with Custom Abutments

- Angle correction allows for more flexibility in implant positioning

- Easier to create a passive fit

- Ideal occlusal anatomy due to no screw-access hole

Disadvantages

- Potential for complications from retained cement

- More interocclusal space is required

SCREW-RETAINED RESTORATIONS

If the implant is placed in an ideal position, screw-retained restorations are optimal because they avoid the risk of residual cement impacting the patient’s hard- or soft-tissue health, and they can be removed with relative ease if needed. In the anterior, positioning is ideal when the access channel of the implant restoration exits through the cingulum. In the posterior, screw retention is appropriate when the access hole emerges through the central groove of the crown. One esthetic advantage offered by screw-retained crowns is that the margin of the titanium base of the restoration is situated well beneath the gingival surface, minimizing metal show-through in cases of thin gingival biotype. Screw-retained restorations are also ideal in cases of limited interocclusal space because less restorative space is required.

One possible downside is that the screw access hole causes esthetic concerns for certain patients, which leads some clinicians to opt for cementable restorations when treating the mandible. There is also the potential for the access hole to compromise the location of occlusal contacts. That said, proper material selection can help seal the access hole in a way that seamlessly blends with the surrounding tooth.

Advantages of Screw-Retained Restorations

- Avoid problems with residual cement

- Simple, efficient crown delivery

- Metal-ceramic transition can be subgingvally deeper

- Less interocclusal space is needed

- Ease of restoration retrieval

Disadvantages

- Best used when implant position is optimal

- Access hole can potentially compromise esthetics and occlusal function

A “SCREWMENTABLE” SOLUTION

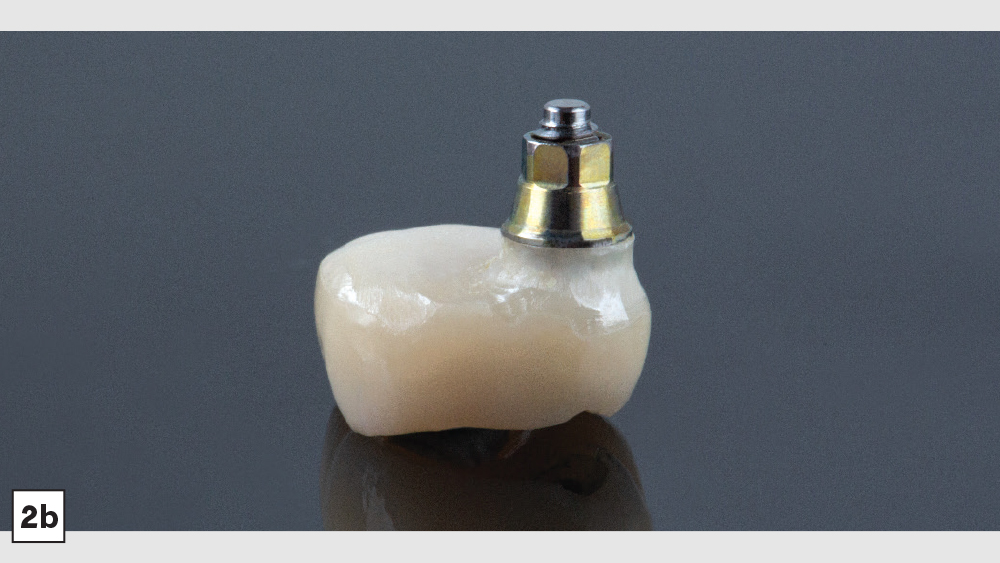

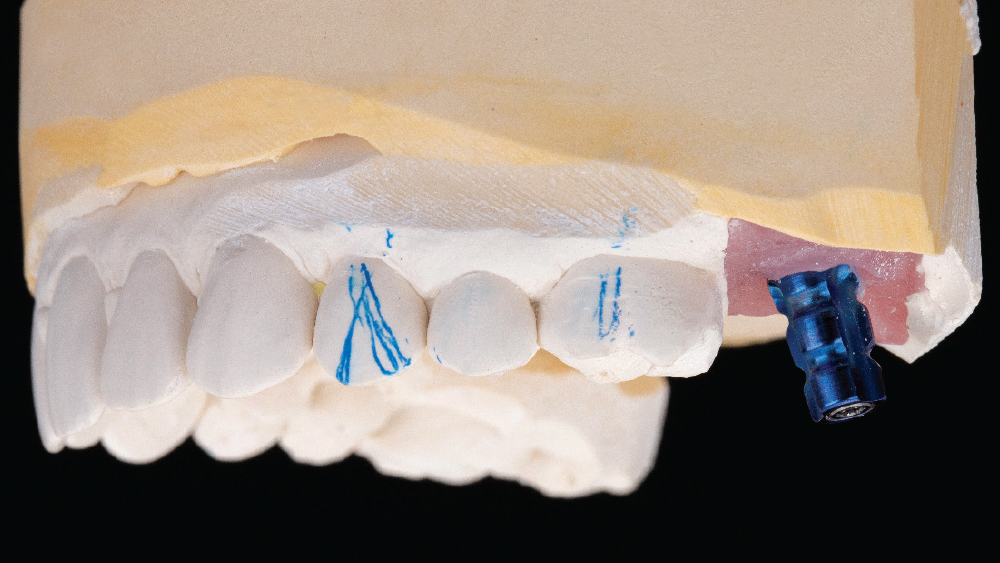

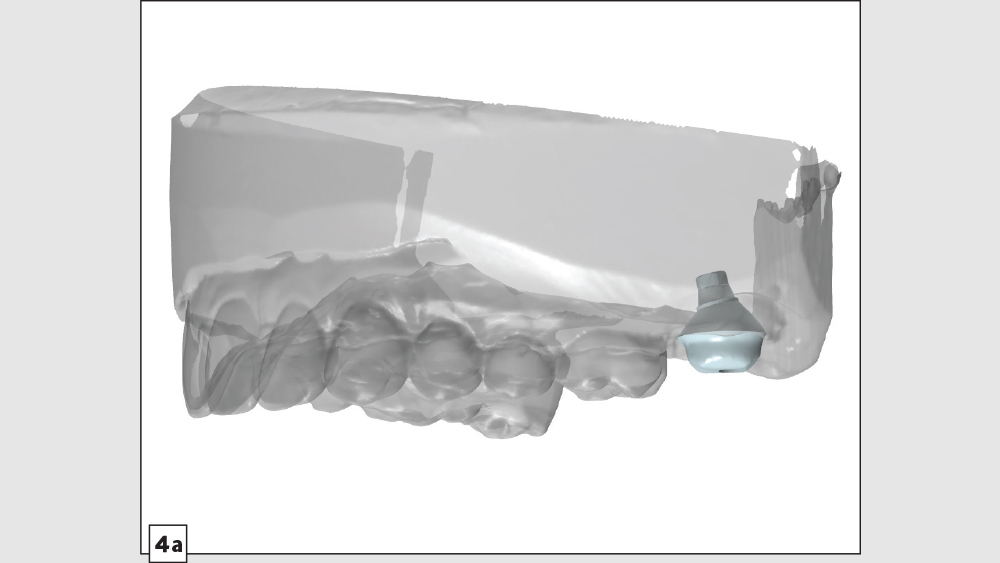

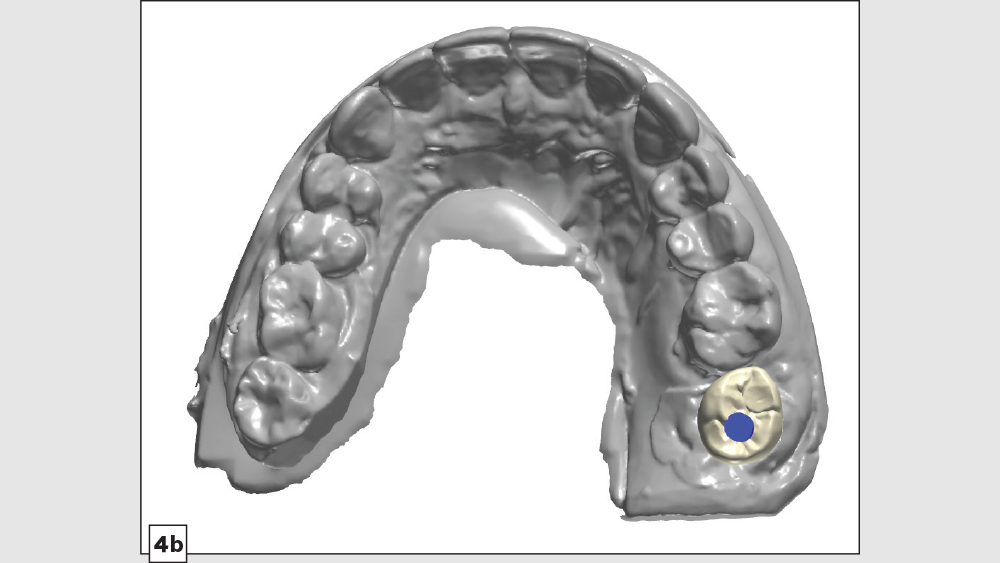

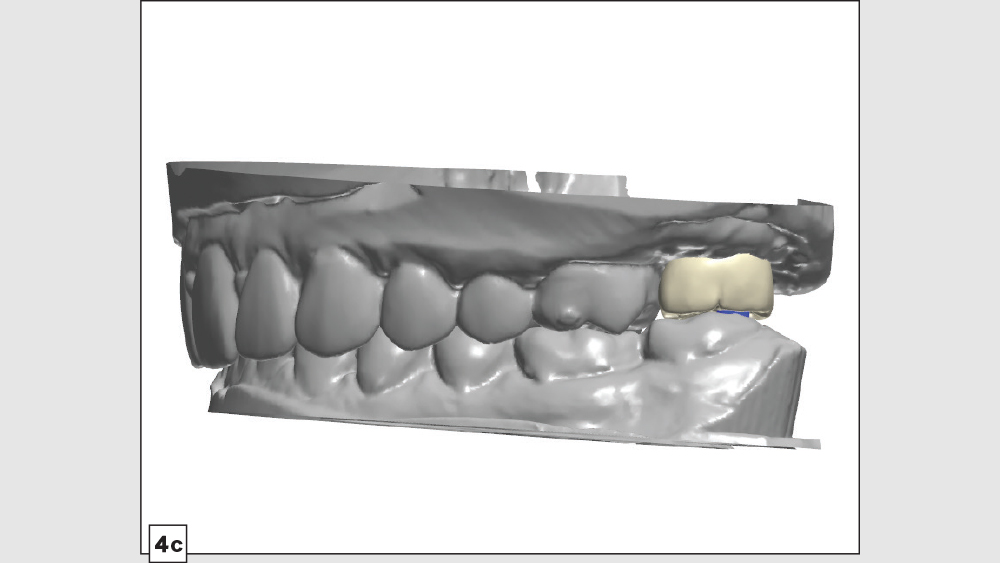

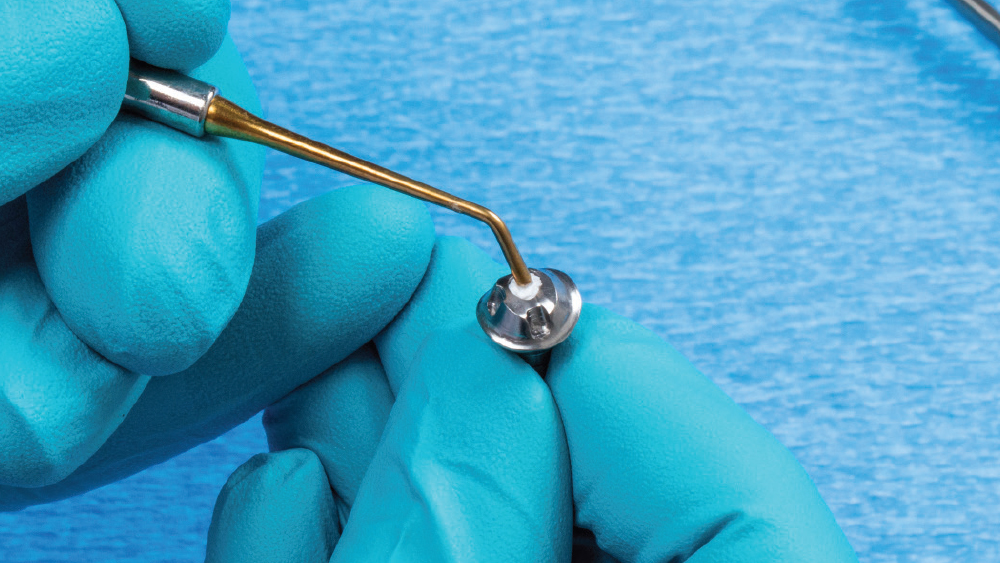

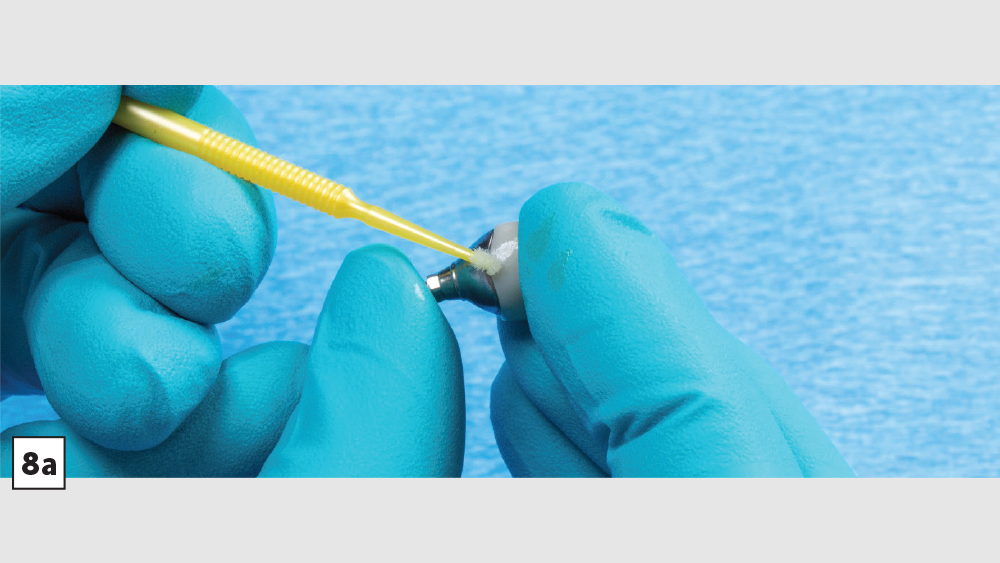

Now that we’ve explored the pros and cons of screw-retained and cementable implant restorations, let’s take a look at a unique clinical situation where the best solution is a hybrid of the two. With a “screwmentable” solution, a custom abutment is designed to support a cementable restoration, but the crown is created with a screw access hole. The cementation portion of restoration delivery — as well as cleanup of any excess cement — is performed outside of the patient’s mouth. This creates what is essentially a one-piece restoration that avoids any concerns regarding retained cement at the implant site, with greater control over the design of the emergence profile.

CASE REPORT

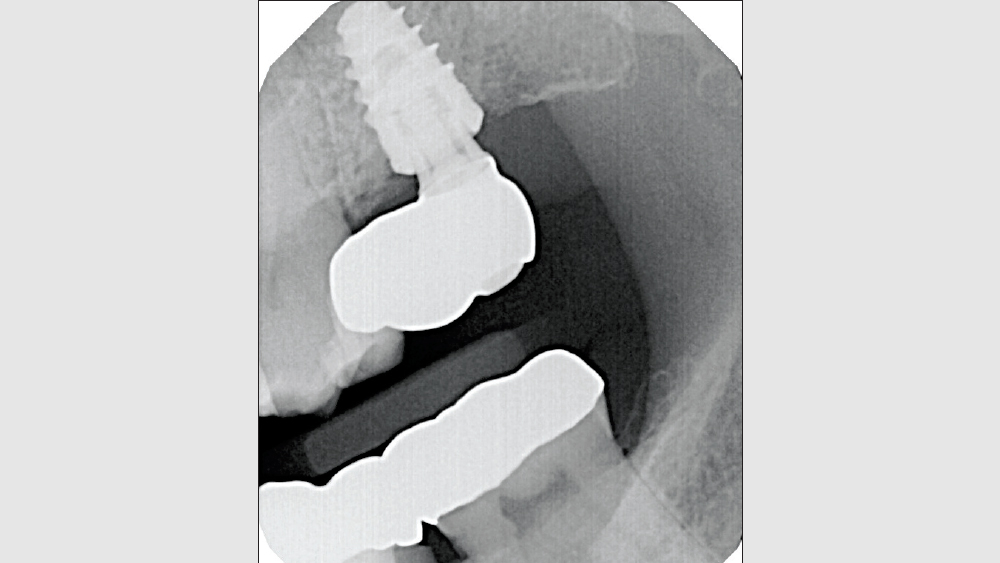

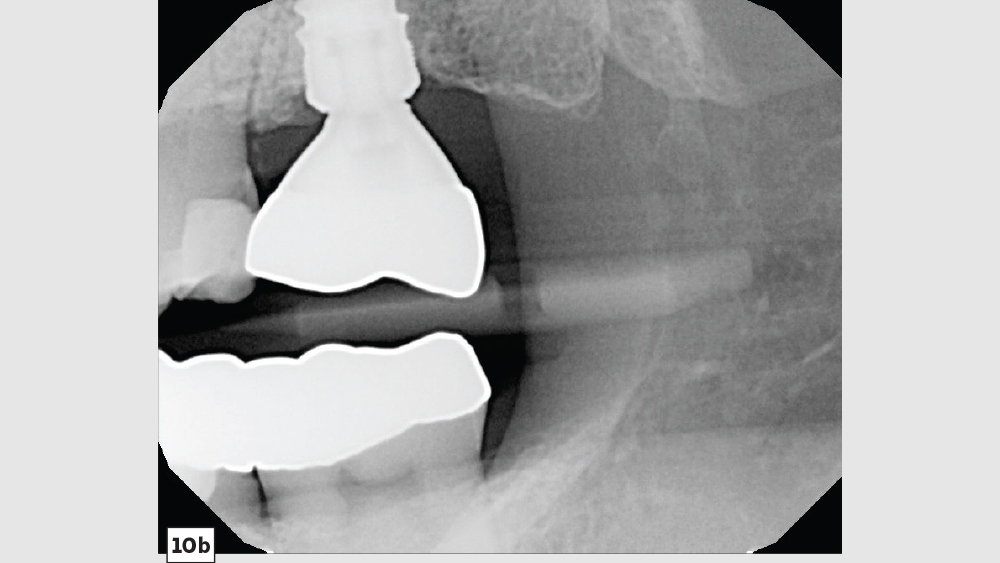

A patient presented with issues concerning a screw-retained crown in the area of tooth #15. She complained that the crown felt loose, was causing food entrapment and was difficult to clean. Upon examination, it appeared that the prosthetic screw was loose and the restoration was mobile. Removal of the crown confirmed that the current design of the prosthesis created a food trap and was not conducive to soft-tissue health. We agreed that the restoration needed to be replaced. A screwmentable restoration was the optimal solution because the malposition of the implant could be corrected by a custom abutment, thereby minimizing the cantilever. We wanted to improve the direction of loading and lessen sheer forces on the implant site by building the restoration out with the titanium structure of the custom abutment. At the same time, because the implant site was in a hard-to-reach area from which cement removal would have been difficult, screw retention was preferred.

CONCLUSION

When determining the optimal type of restoration for an implant case, it is important to consider functional forces, emergence profile, ease of delivery and the potential for prosthetic complications. While screw-retained crowns and cementable restorations over custom abutments both offer certain advantages depending on the circumstances of each case, there are unique situations and restorative challenges that call for a screwmentable solution, affording clinicians one more option as we look to meet the wide-ranging needs of our patients.

NOTE: To prescribe a screwmentable restoration through Glidewell Laboratories, select a custom abutment with crown when you fill out your prescription, and request an access hole in the crown in the case notes. The Implant Fixed Rx can be downloaded here or requested by calling 800-757-4428.

References

- ^Wadhwani C, Piñeyro A. Technique for controlling the cement for an implant crown. J Prosthet Dent. 2009 Jul;102(1):57-8.

- ^Wadhwani C, Rapoport D, La Rosa S, Hess T, Kretschmar S. Radiographic detection and characteristic patterns of residual excess cement associated with cement-retained implant restorations: a clinical report. J Prosthet Dent. 2012 Mar;107(3):151-7.

- ^Wadhwani C, Hess T, Piñeyro A, Opler R, Chung KH. Cement application techniques in luting implant-supported crowns: a quantitative and qualitative survey. Int J Oral Maxillofac Implants. 2012 Jul-Aug;27(4):859-64.