Milled Acetal Partial Dentures: A Clinical Case Report Exploring a New Removable Appliance

It wasn’t long ago that clinicians had few options for a removable partial denture. A cast-metal frame with an acrylic or metal base and denture teeth allowed for a comfortable fit, but the metallic clasps were unsightly and harsh on the soft tissues and supporting teeth. Thermoplastic nylon partials offered a more esthetic option, but were uncomfortable for some patients and came with a higher price tag than traditional metal. Now, innovative materials and techniques offer clinicians a new removable treatment option for partially edentulous patients.

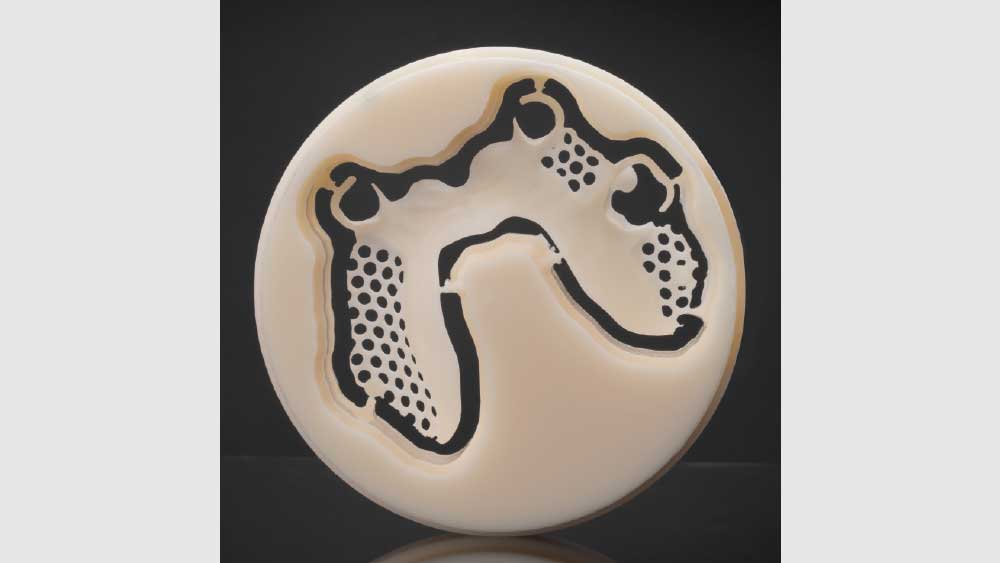

CAD/CAM-fabricated acetal partials are removable appliances, milled from a solid shade-matched acetal block, that offer patients a similar level of comfort to cast-metal partials along with a more esthetic appearance. Milled acetal partials provide clinicians with a high level of accuracy, customization and quick fabrication, and are an additional treatment option for partially edentulous patients who prefer a thin frame but want improved comfort and esthetics.

Additionally, the quick fabrication of acetal partials allows them to be used as provisionals for patients who are not candidates for other temporary solutions like BioTemps® Provisionals.

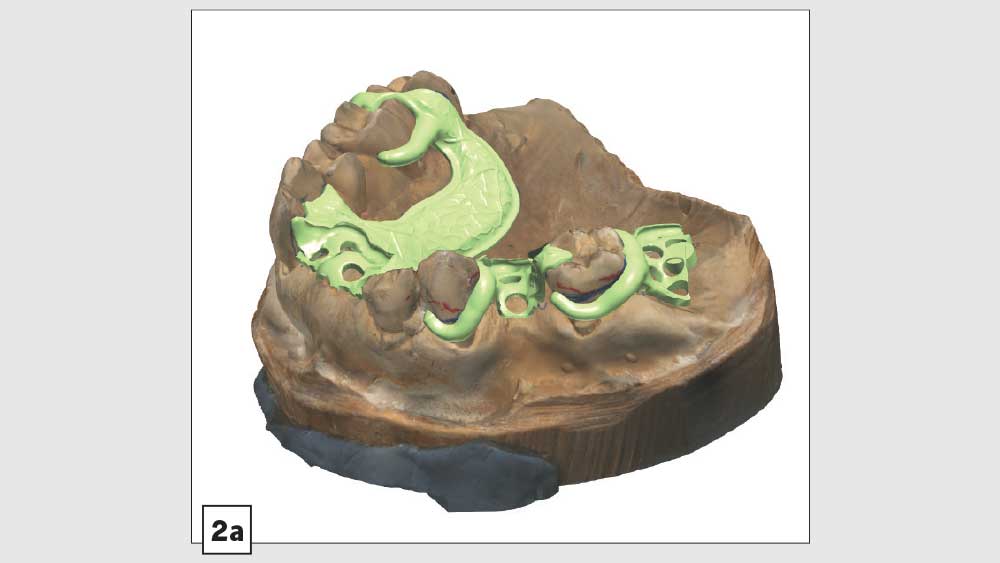

The patient’s stone model is scanned and the acetal frame is milled from a block of acetal resin that is shade-matched to the patient’s teeth. This not only creates a high degree of accuracy to the patient’s anatomy, but also results in an acetal frame that is much thinner than a mold-injected thermoplastic denture. Additionally, for situations where there is limited space for multiple materials, CAD/CAM-fabricated acetal partials allow full-contour teeth to be milled directly into the acetal framework.

Additionally, for situations where there is limited space for multiple materials, CAD/CAM-fabricated acetal partials allow full-contour teeth to be milled directly into the acetal framework.

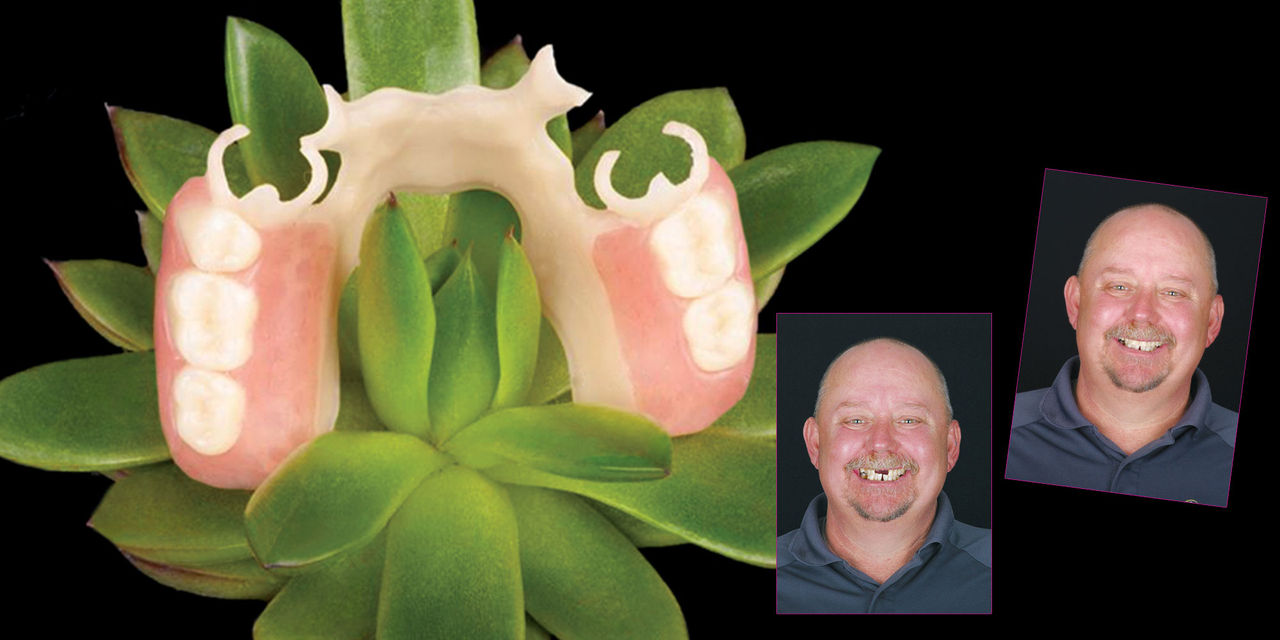

The frame is tried in first, and chairside adjustments can be made to it using a carbide bur. Adjustments can also be made to the acetal tooth clasps by applying heat. If desired, a clear tooth clasp can be added by the lab using CLEARsplint® material. After the frame is sent back to the lab, the denture teeth are waxed in. The denture is then processed, stained and polished. Adjustments to the saddle and occlusion can be made at the final appointment.

CASE REPORT

This patient’s maxillary arch was partially edentulous, missing teeth #3, #5, #8 and #9. Implant restorations or an implant-retained denture were not an option for this patient due to financial constraints. Ultimately, a CAD/CAM-fabricated acetal partial addressed the patient’s request for a more esthetic and comfortable removable partial denture that also stayed within his financial means.

The frame is tried in first, and chairside adjustments can be made to it using a carbide bur. Adjustments can also be made to the acetal tooth clasps by applying heat. If desired, a clear tooth clasp can be added by the lab using CLEARsplint® material. After the frame is sent back to the lab, the denture teeth are waxed in. The denture is then processed, stained and polished. Adjustments to the saddle and occlusion can be made at the final appointment.

BASIC TREATMENT PROTOCOL FOR ACETAL PARTIALS

- Ensure the patient’s remaining teeth are sturdy and caries-free.

- Take impressions, complete the attached discount Rx or the Universal Rx available at glidewelldental.com, and send the case to Glidewell Laboratories.

- The lab will pour and scan the model, and will then create the digital design and mill the acetal frame.

- Receive frame back from lab for try-in.

- Make adjustments to clasps using heat gun, or modify the frame with carbide bur, and send back to lab.

- The lab will add the teeth in wax for an additional try-in if requested.

- Otherwise, the final partial is processed and shipped.

- Receive denture back for final try-in and adjust for comfort.

CONCLUSION

CAD/CAM-fabricated acetal partials offer an esthetic, comfortable alternative to cast-metal partials by using tooth-colored clasps that blend in well, while also being gentler on soft tissues and supporting dentition. Utilizing a CAD/CAM process to mill a shade-matched acetal frame from a single block of resin results in a thinner, more comfortable appliance with a highly accurate fit. Milled acetal partials have demonstrated that they are a viable clinical option for practitioners looking for new ways to help partially edentulous patients who are not candidates for traditional dentures, traditional partials, or implants.

CLEARsplint is a registered trademark of Astron Dental Corporation.