2201 Dupont Dr., Irvine, CA 92612

© 2020-2026 Glidewell. All rights reserved.

800-854-7256 USA

Learn how an existing partial can be digitally duplicated so patients don’t have to go without one.

When a patient presents with an existing removable partial denture that still fits well, but one of the abutment teeth requires a new crown, clinicians face a common challenge: how to fabricate a new crown without forcing the patient to go without their partial. Patients grow attached to their partials — both functionally and emotionally. Asking them to go without their appliance, even for a few days, can be uncomfortable and inconvenient for them.

Traditionally, this process involved multiple appointments, analog duplication, and tedious adjustments. Today, by digitally duplicating the partial’s intaglio surface, clinicians can design a crown that precisely conforms to the appliance’s contours. The result is a restoration that fits seamlessly beneath the existing partial, eliminating the need for patients to go without it during fabrication.

Utilizing this technique benefits both patients and clinicians:

This method also works for crowns adapted to complete dentures, nightguards and implant cases.

For any new crown to fit properly under an existing appliance, the crown must conform to its clasps, rests and axial contours. It’s important to pay close attention to the fit of the existing appliance.

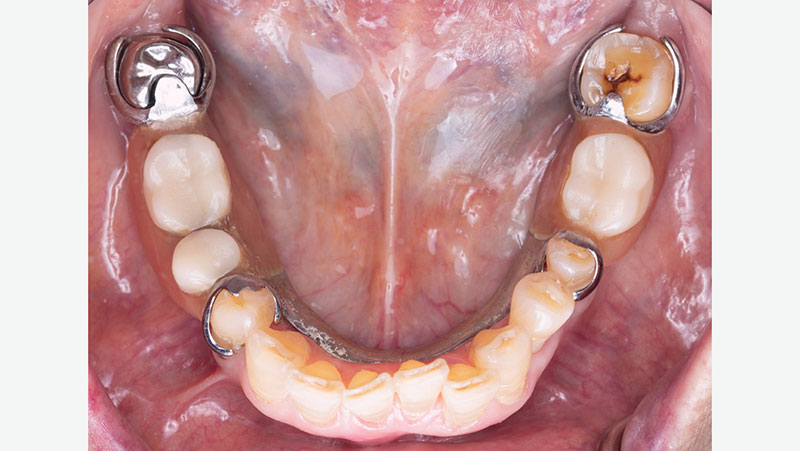

For existing partials, examine the occluding tooth contact, the position of the tongue, how the retentive and reciprocal arms are placed, and how it rests on the occlusal surface of the crown. Be sure to also examine the patient’s oral environment when the partial is removed, noting the spacing and the gingival region around the crown.

Original crown without partial

Partial over original crown

Occlusion without partial

Ridge spacing without partial

Intraoral scanning can dramatically reduce the risk of remakes and improve patient comfort during this process. Devices like the fastscan.io™ Scanning Solution can be used to complete this process and provide a predictable, simple way to achieve higher accuracy.

1. Take an initial preoperative scan without the partial in place to capture the contours and occlusal anatomy of the patient’s current abutment tooth.

2. Take a physical impression of the preoperative tooth to make a provisional.

3. Prepare the tooth.

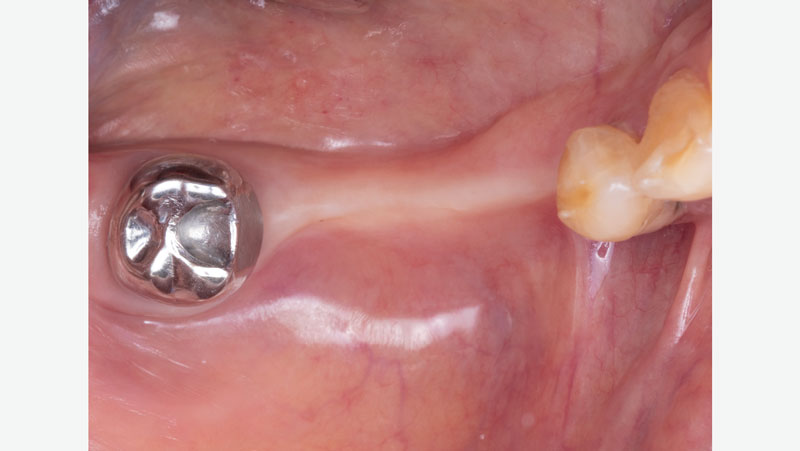

4. Retract the soft tissue that could obscure the margin and prevent a complete and accurate scan.

5. Scan the tooth prep without the partial in place.

6. Take a scan in bite position for an accurate bite registration with the partial in place.

7. Send the scan files to your laboratory, along with the appropriate prescription.

8. Seat the provisional and adjust it so the partial denture fits comfortably.

Crown preparation with retraction cord, ready for scanning.

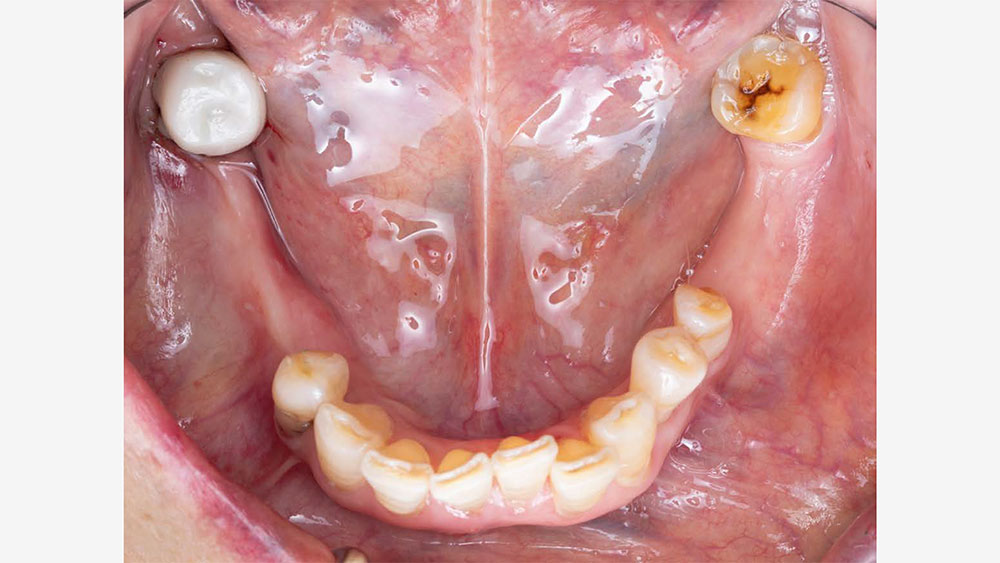

Final BruxZir crown without partial.

Partial over final BruxZir crown.

NOTE: For doctors using in-office milling systems like the fastmill.io™ In-Office Mill, simply use the preoperative scan as the crown design, so you can mill a crown identical in shape to the existing tooth.

As part of the lab’s quality control process, Glidewell supplies a 3D-printed model and a removable pattern of the partial along with the final crown. This is done in order to check the path of insertion, confirm proper seating and verify engagement with the crown. The photos below show an example of a 3D partial duplicate and model that were supplied with a final crown.

Before the advent of digital technology, fabricating a crown beneath an existing partial was a complex and often frustrating clinical process. With today’s intraoral scanning and CAD/CAM capabilities, clinicians can achieve a simplified, predictable, patient-friendly workflow — whether cases are fabricated in-office or through Glidewell’s digital laboratory. This innovation reinforces the modern dental practice’s ability to combine efficiency, precision, and patient comfort — all in a single, streamlined appointment sequence.

To learn more about partials or to download an Rx, visit glidewelldental.com/solutions/removable-prosthesis/partials.

Related Article

Send blog-related questions and suggestions to hello@glidewell.com.