An Evaluation of Mouthguard Materials

Objective

To compare the impact protection and physical properties of two traditional multi-laminated custom mouthguards (PlaySafe® Light Pro and Heavy Pro [ERKODENT Erich Kopp; Pfalzgrafenweiler, Germany]) to all-in-one single-laminate mouthguards (PlaySafe Triple Light and Triple).

Background

Custom mouthguards are favored by clinicians in every respect over the store-bought varieties. A custom mouthguard reduces complaints related to speech limitations and comfort concerns when used in sports,1 and features less thickness reduction2 compared to boil-and-bite and stock mouthguards. This provides the formula for a stronger and more comfortable mouthguard for the athlete. Although custom mouthguards cost more and require a dentist’s expertise, the performance is unmatched by over-the-counter varieties. It is a concern that many youths playing impact sports for the first time and professional athletes alike are not aware of the advantages of custom mouthguards.

Common versions of modern custom mouthguards are made from laminated materials. A theory behind the performance enhancement in laminated mouthguards is that softer materials offer better protection from hard object forces, and harder materials offer better protection from softer object forces.3 When using a combination of hard and soft layers, it allows a balance of force absorption and force redistribution as needed for a wider range of impact types. Lamination also provides more stability in anterior mouthguard thickness when thermoforming.4 This ensures the most residual thickness is left protecting the teeth after the wedge-shaped incisors distort the incisal edge of the mouthguards during thermoforming. When the full complement of laminations is considered, the thickness loss in the incisal edge is less.

For PlaySafe sports mouthguards from ERKODENT, two thicknesses of three-layer laminated mouthguards are available. Light Pro is marketed at 3 mm thick, and Heavy Pro is marketed at 5 mm thick. However, laminated mouthguards are labor-intensive to create. Because of this, two apparently equivalent mouthguards are now available that offer the improvements of lamination — such as enhanced impact protection and incisal thickness stability — plus the ease and speed of thermoforming single-layer mouthguards. Triple Light and Triple have been tested by ERKODENT laboratories with the conclusion that they not only provide the same or better performance as their Light Pro and Heavy Pro counterparts, but they are also thinner and lighter.5

Methods

A maxillary dentiform impression was sent to Glidewell Laboratories to form two samples of each mouthguard: Light Pro, Heavy Pro, Triple Light and Triple. When received, the mouthguards were all weighed and the mouthguard facial thickness of teeth #6–11 was measured with digital calipers at the center of the facial surfaces.

Each testing model was created with Integrity® bis-acryl crown and bridge provisional material (DENTSPLY Caulk; Milford, Del.) and DENTSPLY pink denture repair material. A die saw was used to create interproximal spaces between anterior teeth.

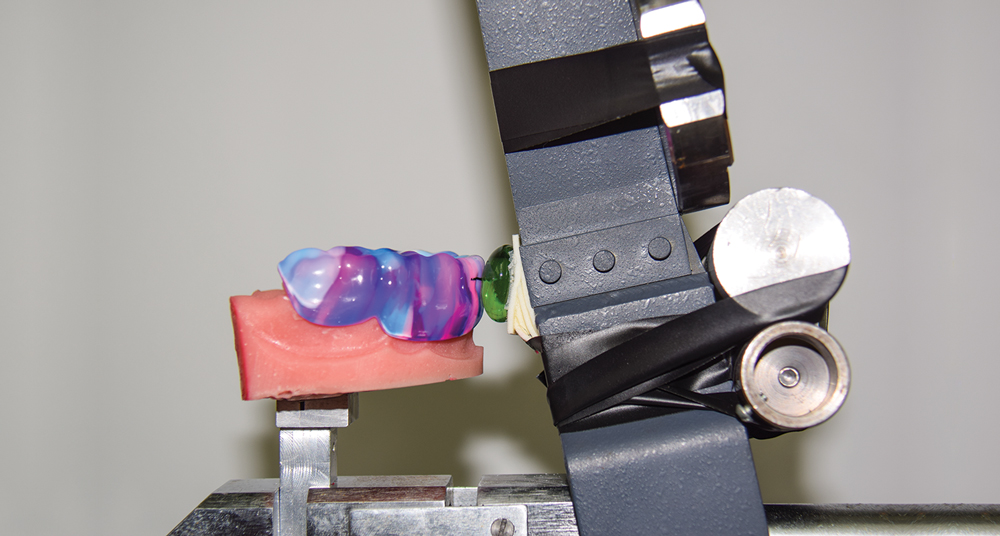

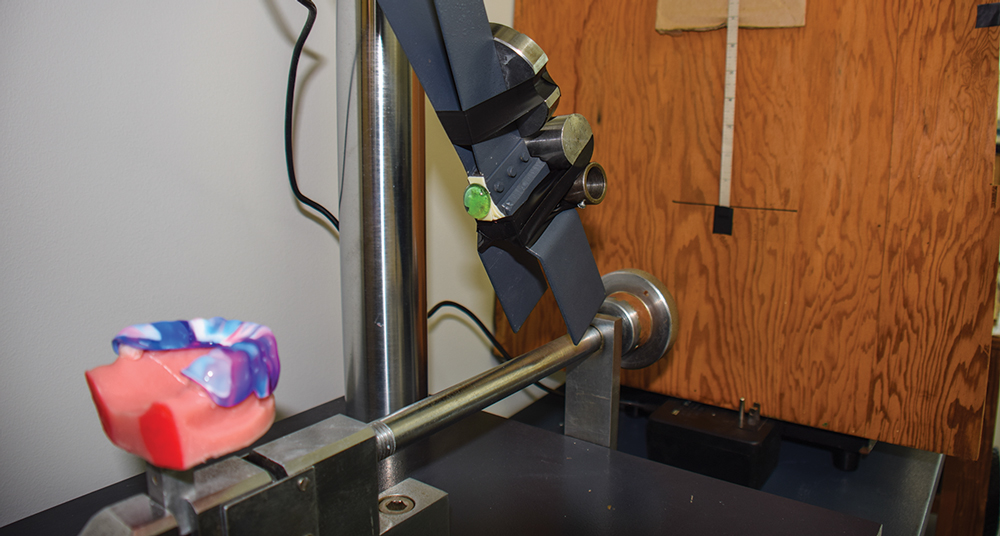

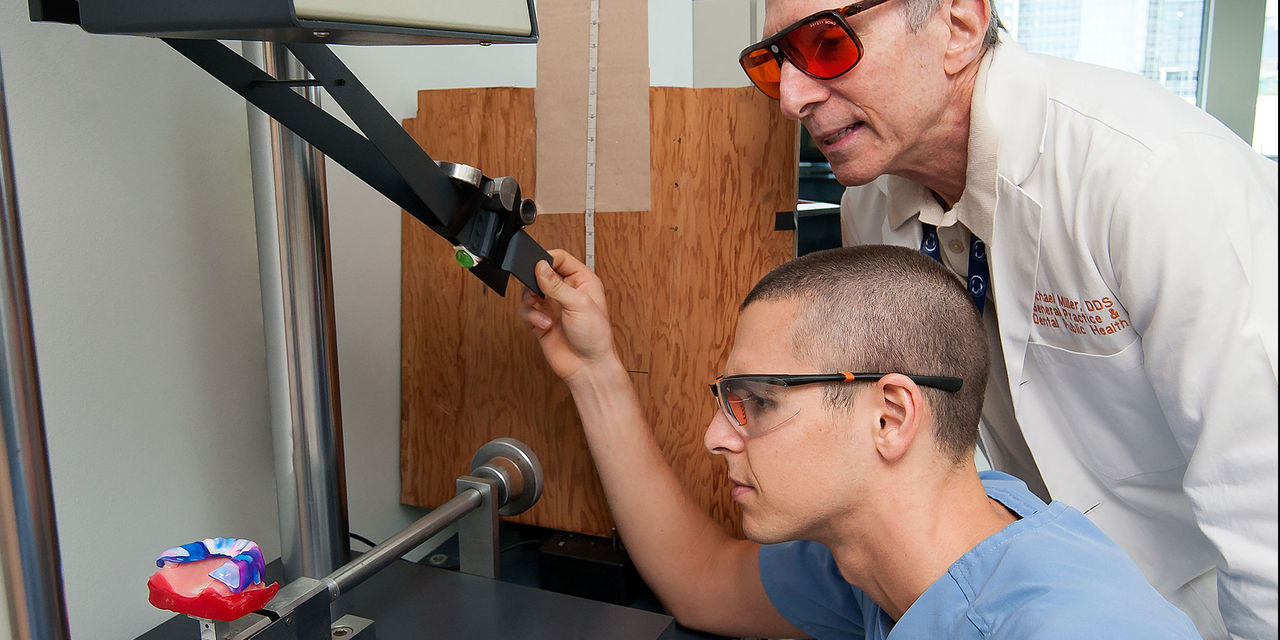

Each model with an attached mouthguard was placed on the aluminum sample holder with the model recess. The vertical dimension was set where the center line on the mouthguard matched the center of the impacting surface. The impacting surface was a semispherical glass marble affixed with double-sided padded tape. The completed apparatus at rest is shown in Figure 1a.

Tests were performed by releasing the pendulum from either low force at 8.5” vertically high from impacting center, medium force at 9.5” high or high force at 12.5” high (Fig. 1b).

Results

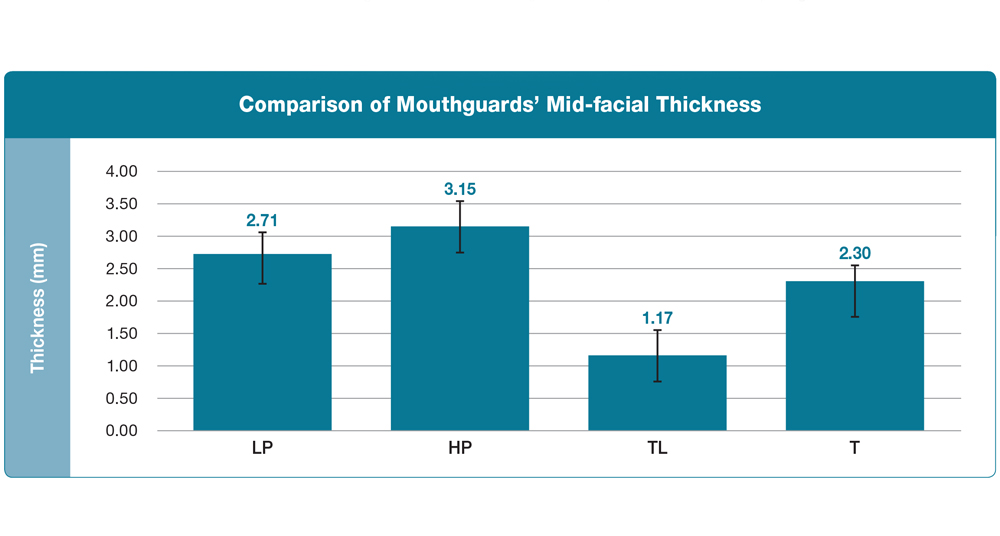

Mid-facial thickness measurements were averaged from tooth #8 and #9 between both samples for each mouthguard type. Additionally, weight was recorded. Thicknesses and weights correlated well with each other. Triple Light was the thinnest by far at an average of 1.17 mm. Triple was the second thinnest at an average of 2.30 mm (Table 1).

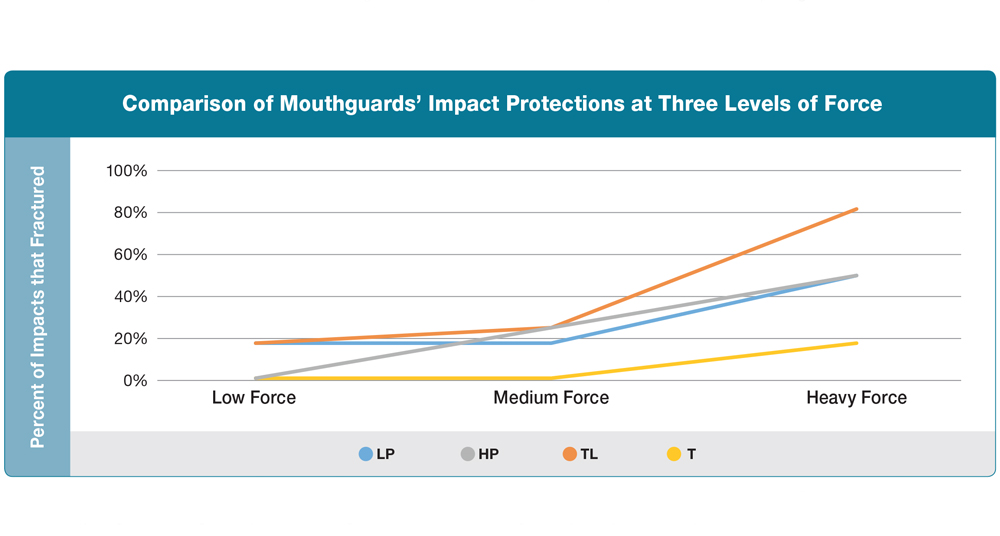

For impact protection (Table 2), each mouthguard type was subjected to six total trials at each force level. Triple Light fractured more frequently at each force than the other mouthguards. Triple fractured the least across all forces. Light Pro and Heavy Pro performed similarly in between Triple Light and Triple. Results were recorded as either positive or negative for tooth fracture at each trial. Significant differences were found between Triple Light and Triple at high force.

Discussion

The pre-impact measurements parallel much of the findings from ERKODENT laboratories.5 According to their published testing, facial thickness at the central incisor was 20 percent thinner in Triple than that of Heavy Pro; our study measured 27 percent more thinness in Triple than that of Heavy Pro. ERKODENT labs also measured Triple with a 32 percent weight reduction from Heavy Pro; our findings showed only a 13 percent weight reduction. ERKODENT did not present data for Triple Light and Light Pro, but the product information also depicts a significant reduction in weight and thickness for Triple Light when compared to Light Pro. Our study showed a 57 percent decrease in thickness and a 21 percent decrease in weight with the Triple Light in comparison to Light Pro. Thicknesses of the conventional mouthguards did not violate the commonly accepted parameter of 4 mm of maximum thickness for comfort.6

The impact data and test are not directly comparable to that of the ERKODENT labs because of a difference in testing protocol; however, our results suggest the same finding where Triple has as much protective capability as Heavy Pro.5 Moreover, our data suggests that the Triple may even exceed Heavy Pro in protective ability at high forces. When comparing Triple Light and Light Pro, we also found no statistically significant difference between the two mouthguards. ERKODENT confirms this finding in its “New Products IDS 2015” brochure.7 Our study found a statistically significant difference between Triple and Triple Light. Not only is this consistent with ERKODENT lab data, but it also demonstrates that Triple thickness is necessary for high force impacts compared to Triple Light.

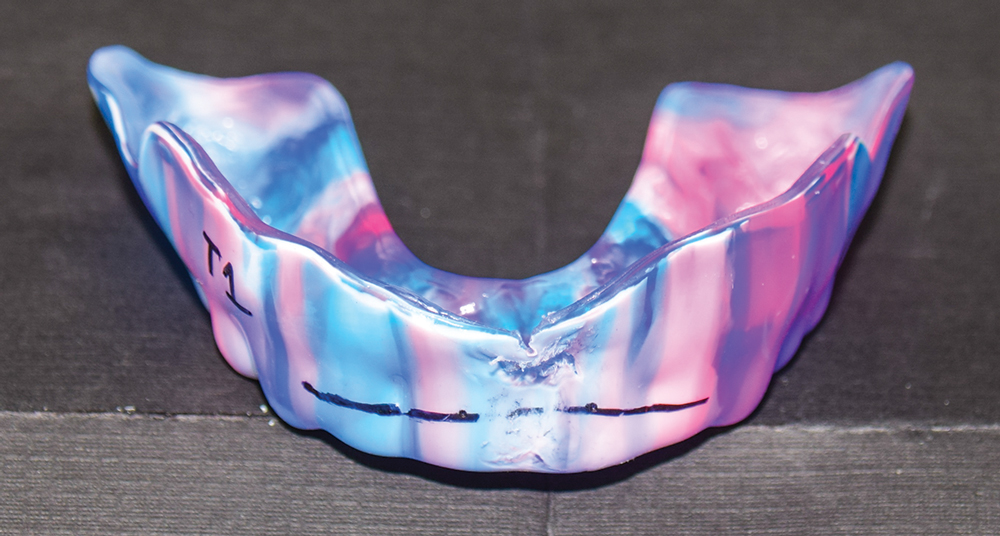

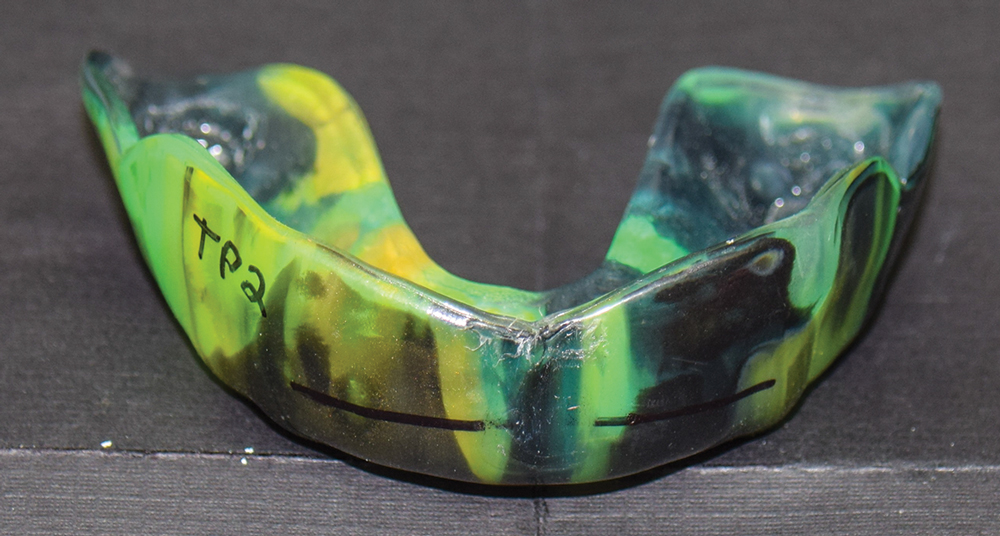

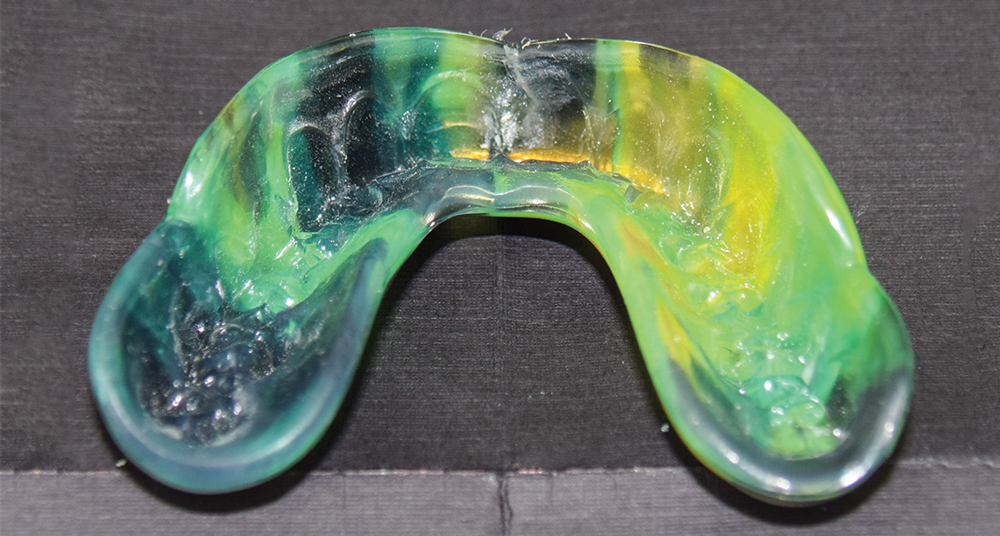

An unexpected finding in our testing was the wear-resistance difference between Triple Light and the other mouthguard types. Triple Light took only two trials before it was perforated. All other mouthguards received only minor damage (Figs. 2a–2d). More studies are needed on the effects of physical wear on mouthguards and impact performance.

Conclusions

The new single-laminate Triple had the best protection despite being the second-thinnest and lightest of the mouthguards tested. By contrast, the other new single-laminate, Triple Light, had the least effective protection and durability. Triple Light’s inferior performance in this test, despite being composed of the same materials and undergoing the same thermoforming processes as the best performing mouthguard, demonstrates that there is a thickness threshold that does not allow Triple Light to be as effective at higher impacts. Conventional three-laminate mouthguards, Heavy Pro and Light Pro, provided moderate levels of protection at thicker facial dimensions. Thicknesses of the conventional mouthguards did not violate the commonly accepted 4 mm of maximum thickness for comfort.6

The results indicate athletes would not be compromising impact protection by using a thinner, lighter, single-laminate, all-in-one mouthguard; however, athletes may want to choose the relatively heavier Triple over the lighter Triple Light for high-impact sports like football and boxing. The Triple variety may also show superior impact protection compared to even the heavier, conventional three-laminate mouthguards, Heavy Pro and Light Pro.

Acknowledgments:

Glidewell Laboratories fabricated the mouthguards for this study. Photo courtesy of Brian Schnupp.

References

- ^Seals RR, et al. An evaluation of mouthguard programs in Texas high school football. The Journal of the American Dental Association. 1985 Jun;110(6):904-9.

- ^Park JB, et al. Improving mouth guards. J Prosthet Dent. 1994 Oct;72(4):373-80.

- ^Takeda T, et al. The influence of impact object characteristics on impact force and force absorption by mouthguard material. Dent Traumatol. 2004 Feb;20(1):12-20.

- ^Miura J, et al. Mouthguards: difference in longitudinal dimensional stability between single- and double-laminated fabrication techniques. Dent Traumatol. 2007 Feb;23(1):9-13.

- ^Comparison of PlaySafe Triple and PlaySafe Heavy Pro [internet]. Pfalzgrafenweiler (Germany): Erkodent; [cited 2015 Aug 9]. Available from: http://www.erkodent.com/dental/download/powerpoint/PlaysafeComp16_9.pdf.

- ^Maeda M, et al. In search of necessary mouthguard thickness. Part 1: From the viewpoint of shock absorption ability. Nihon Hotetsu Shika Gakkai Zasshi. 2008;52(2):211-9.

- ^New Products IDS 2015 [internet]. Pfalzgrafenweiler (Germany): Erkodent; [cited 2015 Aug 9]. Available from: http://www.erkodent.com/dental/download/sonst/neuIDS_2015_EN.pdf.