R&D Corner: Is Your Zirconia Hiding a Secret?

In the world of dental zirconia, there’s an emerging problem that’s not widely known by dental practitioners — one with perhaps significant consequences to patients. Manufacturers across the industry are exploiting the specifications put forth by the International Organization for Standardization (ISO) and reporting exaggerated flexural strength ratings. It’s possible that the new-generation zirconia bridge that you seated with the manufacturer-claimed flexural strength of 1,000 MPa actually only had a flexural strength of 750 MPa. How significant is that? A durability loss of 250 MPa would be so substantial that the material’s ISO-recommended use would change entirely. It would no longer be suitable for restorations that exceed 3 units.

THE WIDELY USED PRESS METHOD — AND ITS LIMITATIONS

To better understand how manufacturers can manipulate the ISO reporting standards, let’s take a look at what goes into a zirconia product and the press process that manufacturers commonly use.

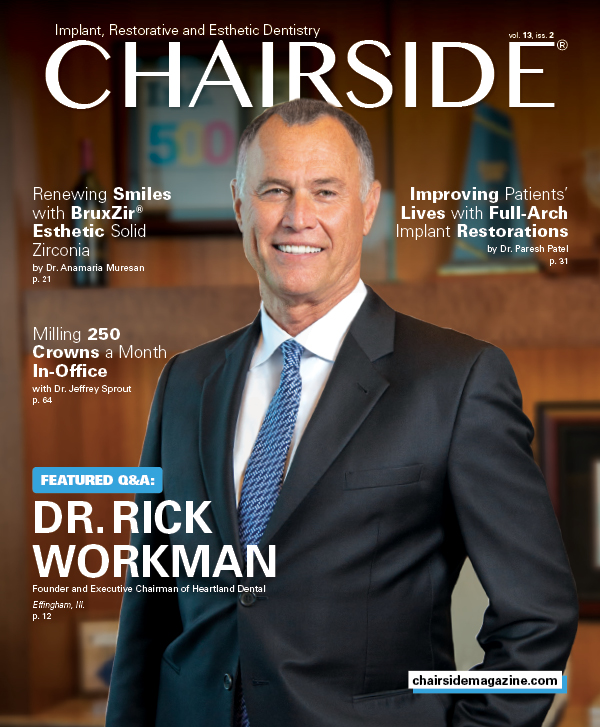

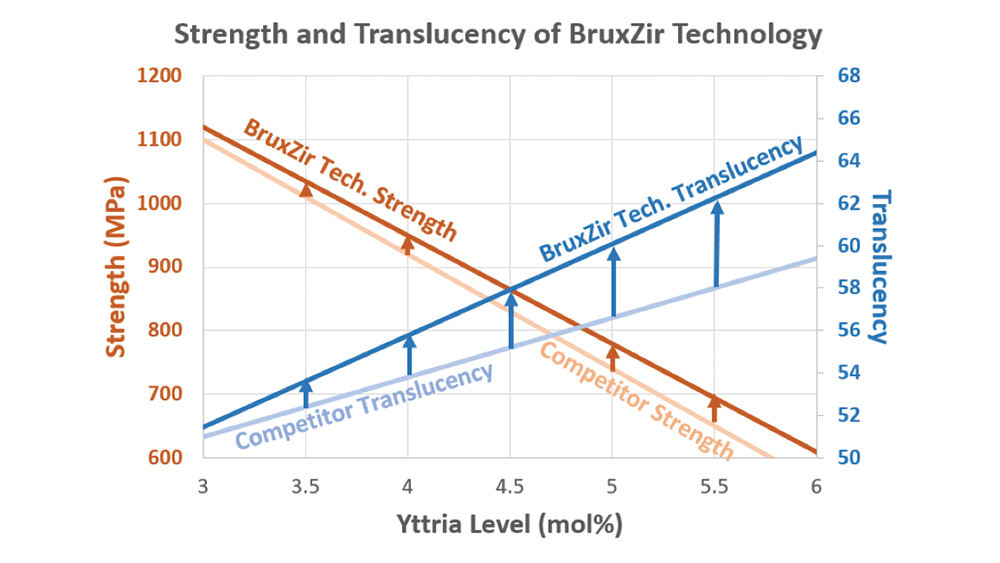

All restorative dental zirconia powders include zirconia (ZrO2) and a stabilizing material, which is typically yttrium oxide (yttria). As yttria is added to the mix, strength decreases, and translucency increases (Fig. 1).

Figure 1: There exists a defined relationship between yttria and zirconia: As yttria is added to the mix, strength decreases, and translucency increases. High-strength dental zirconia will have less yttria, and high-translucency dental zirconia will have more.

The raw materials supplier delivers premixed zirconia powder that contains a specified percentage of yttria, along with a binding element. This raw powder is loaded into a machine that applies hundreds of tons of pressure for a few seconds to form a hockey puck-like milling blank. The blank undergoes a heating cycle to extract the binding element and harden the blank.

This press process is well-known, relatively affordable and fast. However, the press process does not add to the qualities of the material. Rather, the material’s major qualities are already established by the ingredient ratios of the yttria-stabilized zirconia powder.

Considering manufacturers are using the same raw materials and a very similar manufacturing process, it stands to reason that the restorative products on the market should all have similarly reported flexural strengths, translucency levels and touted benefits. However, as you have likely seen in advertisements and journals, that’s not the case.

HOW MANUFACTURERS ARE EXPLOITING THE ISO STANDARD

The ISO standard for dental ceramics has been the defining rulebook for measuring materials’ strength qualities since the mid-1980s. With such a wide variety of dental material classes available, the standard permits multiple testing methods for quantifying strength.

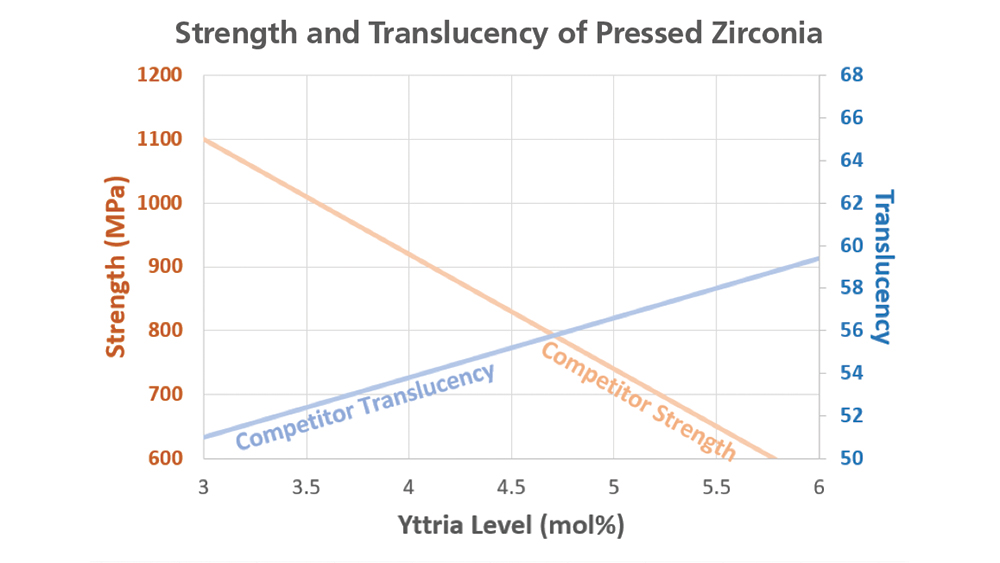

Traditionally for dental zirconia, the three-point flexural strength test has been utilized. A zirconia bar is placed across two supporting pins, and a third point applies pressure at the midpoint until material failure occurs (Fig. 2).

Figure 2: In the three-point flexural strength test, a sample bar is positioned across two supporting pins, and a third point applies pressure downward at the midpoint of the material until failure occurs.

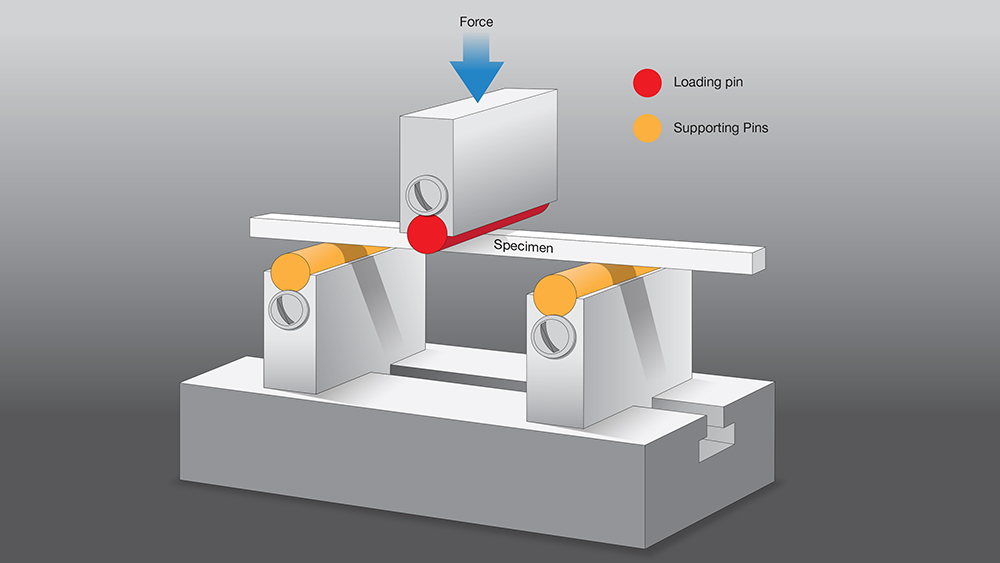

Figure 3: In the biaxial strength test, a sample disc is placed within a testing unit, and a flat punch applies pressure at the center of the disc until failure occurs. The ISO standard permits various surface treatments to be applied to the sample disc, which results in elevated average flexural strength ratings.

However, some manufacturers are exploiting leeway in the ISO standard’s allowance of a different method: the biaxial strength test, in which a sample disc is placed within a testing unit, and a flat punch applies pressure at the center of the disc until failure occurs (Fig. 3).

Why would manufacturers prefer this test? For dental zirconia, biaxial strength testing generates a higher flexural strength reading than does the three-point flexural strength testing technique.1 The biaxial strength test can be easily manipulated using tactics like various surface treatments.

This means that most zirconia products on the market today are labeled with inflated flexural strengths. These manufacturers have taken away the clinician’s ability to make informed decisions for patients.

THE GLIDEWELL DENTAL DIFFERENCE: A LEGACY OF SERVICE

If the majority of manufacturers are being disingenuous with their flexural strength boastings, what makes Glidewell Dental or BruxZir® Solid Zirconia any different?

Firstly, Glidewell Dental has a proven, long-standing commitment to dentists to provide high-quality products at affordable prices. We’ve invested hundreds of millions of dollars and decades of scientific research to revolutionize the materials we offer. Our laboratories serve tens of thousands of clinicians worldwide every year. We would not jeopardize our reputation by purposefully misstating a material’s clinical abilities.

Secondly, while we are a manufacturer of dental zirconia, we’re also a large consumer. Milling blanks manufactured at Glidewell Dental are used in our own laboratories, too. If we manufactured a lower quality zirconia blank that exaggerated its clinical usefulness, we ourselves would stand to suffer the most. To best ensure that our dentist customers and Glidewell technicians can rely on BruxZir materials, we only utilize the three-point flexural strength test.

Lastly, the release of the original full-strength BruxZir Solid Zirconia signified a sea change in the industry. In a mere decade, more than 16 million BruxZir restorations have been prescribed. In that same amount of time, we have conducted rigorous zirconia research and spent millions of dollars on technology to maintain our position as the true zirconia expert. We are not going to risk our reputation on inflated strength claims.

We are committed to applying our scientific expertise in order to continually improve BruxZir formulations and invent new materials.

A NEW, HIGH-STRENGTH SOLUTION: BRUXZIR® ESTHETIC

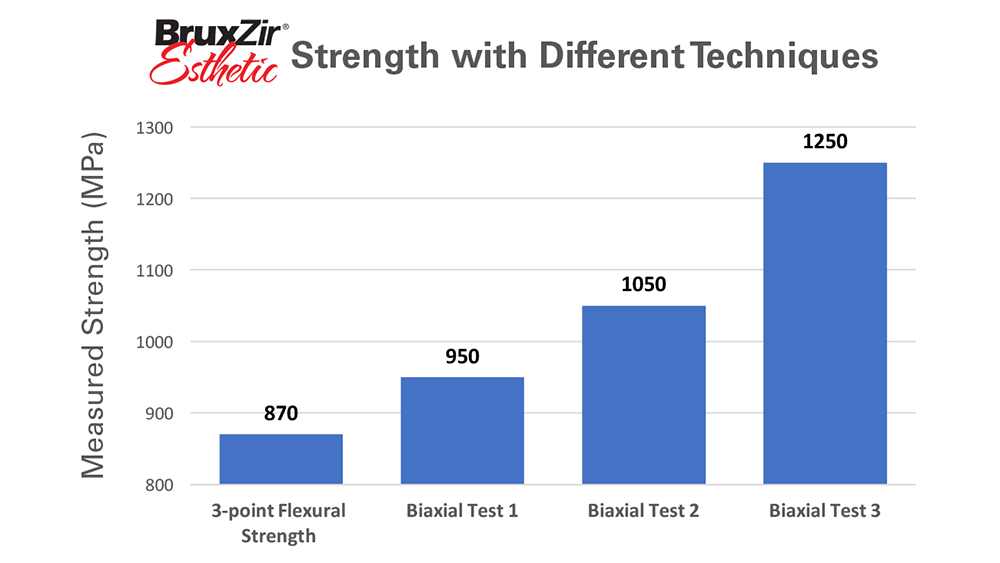

After years of research & development, BruxZir Esthetic Solid Zirconia is available today as the first true anterior-grade zirconia formulation. Made possible through proprietary processing techniques, BruxZir Esthetic restorations exhibit natural translucency and beautiful shade-matching capabilities in conjunction with an average flexural strength of 870 MPa that’s been verified by the ISO three-point flexural strength test.

Proprietary Colloidal Processing

Whereas the majority of other zirconia brands on the market use the press process, BruxZir Esthetic zirconia and the original BruxZir Full-Strength zirconia are unique in that they utilize a super-refined zirconia powder and proprietary colloidal processing.

Glidewell Dental purchases a custom blend of yttria-stabilized zirconia powder from the Tosoh Corporation that does not have binding elements like other zirconia powders. We further reduce the size of the zirconia particles by using an innovative grinding process. As a result, the zirconia particles in BruxZir powder are extremely uniform, exceptionally small and free of unnecessary additives.

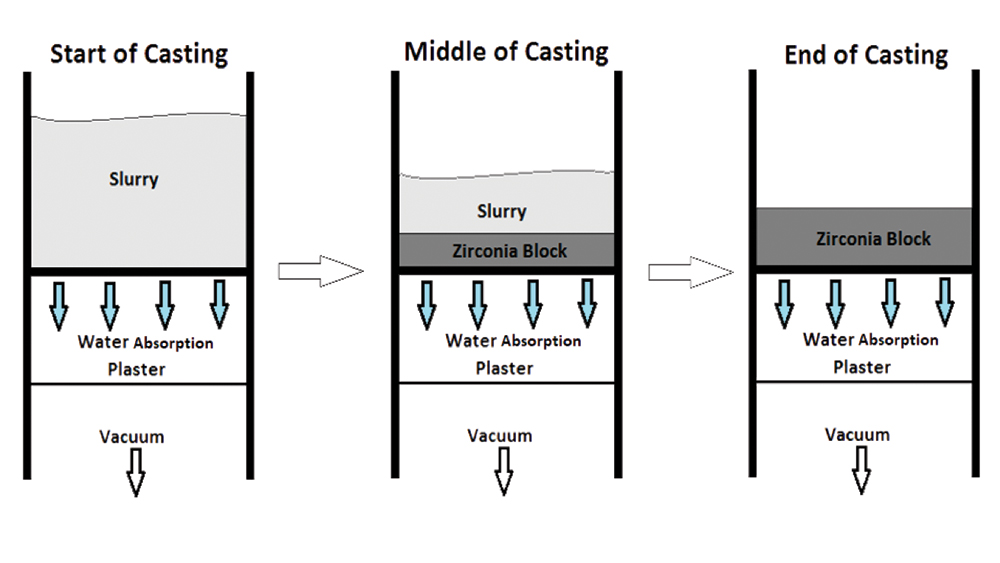

This highly uniform powder is then processed through the BruxZir colloidal technique. The zirconia powder is mixed with liquid, and then the liquid is slowly extracted. This occurs by placing the zirconia slurry into a container with a plaster base that can absorb the liquid. It acts similar to a sieve and essentially vacuums out all the fluid (Fig. 4). What’s left is a zirconia milling blank that goes through a drying cycle and is prepared for laboratory use.

Figure 4: In the colloidal process, a zirconia slurry is placed into a container with a plaster base that can absorb the liquid but not the zirconia powder, acting much like a sieve. The liquid dissipates over a period of time until only a zirconia blank remains.

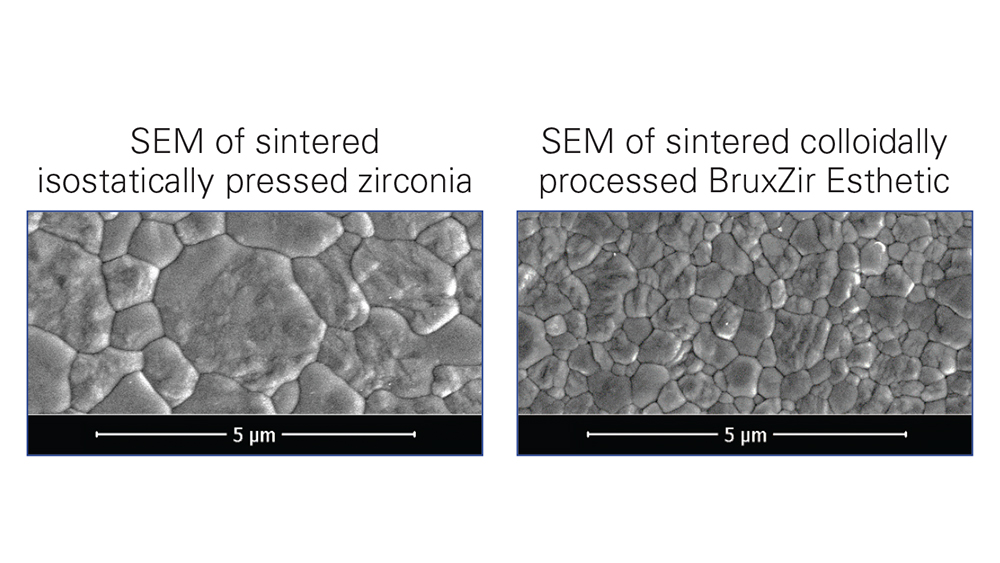

Figure 5: Colloidal processing and pretreatment of BruxZir zirconia powder result in a zirconia material that’s arranged in an enhanced, compact pattern. This imparts the final BruxZir restoration with increased strength and translucency compared to restorations that are created with the press process.

The benefit of colloidal processing is that the slow action of liquid extraction allows the natural forces of physics to organize the individual zirconia particles into an enhanced, compact pattern (Fig. 5).

By using the colloidal process, our custom zirconia powder and other proprietary techniques, restorations made of the BruxZir Full-Strength and BruxZir Esthetic materials achieve results that are virtually impossible with pressed zirconia. These enhanced manufacturing methods allow the final material to achieve the true possibilities of yttria-stabilized zirconia (Fig. 6).

Figure 6: This chart depicts how the colloidal process and other proprietary BruxZir production techniques establish a new relationship between yttria and zirconia, resulting in material benefits that are not achievable through the press process used by competitors.

BRUXZIR ZIRCONIA: THE ZIRCONIA YOU CAN TRUST

The BruxZir Full-Strength and BruxZir Esthetic formulations are in a different classification than zirconia materials that are manufactured using the press process. Our manufacturing process makes our zirconia products distinctively strong. We do not need to bend the ISO standard to artificially inflate our flexural strength claims.

In fact, if we were to rely on the testing methods used by other manufacturers, we could boast a flexural strength far greater than 870 MPa for BruxZir Esthetic zirconia (Fig. 7). At Glidewell Dental, we’re committed to only showing accurate strength values that represent the material’s capabilities in a way that’s useful to the clinician. Our commitment is to you and your ability to make high-quality restorative solutions accessible to your patients.

Figure 7: To demonstrate the stark difference in results generated by the three-point flexural strength test versus the biaxial strength test, we analyzed BruxZir Esthetic zirconia using a variety of testing methods. The traditional three-point flexural strength test produced the lowest results, whereas biaxial strength tests produced results that were substantially higher.

References

- ^Xu Y, Han J, Lin H, An L. Comparative study of flexural strength test method on CAD/CAM Y-TZP dental ceramics. Regen Biomater. 2015 Dec;2(4):239-44.