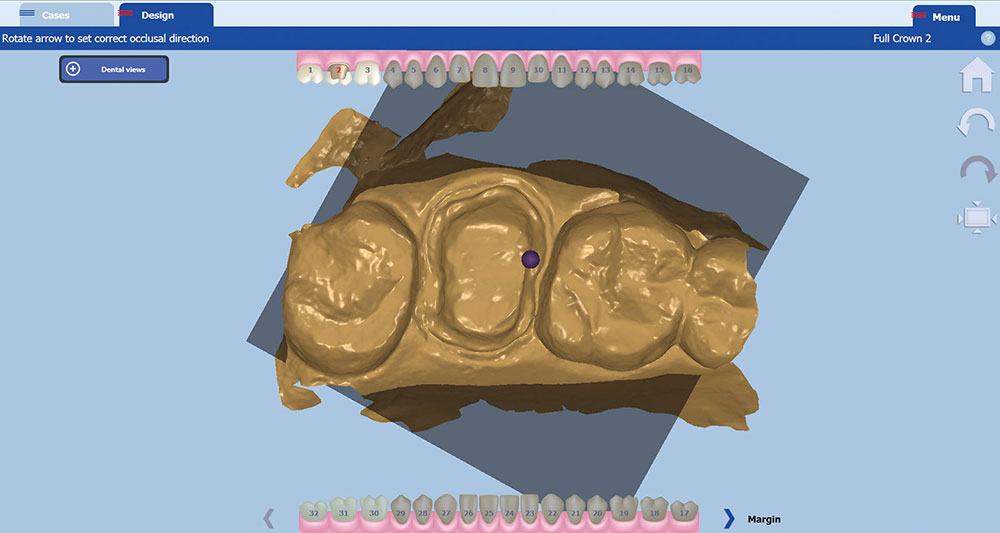

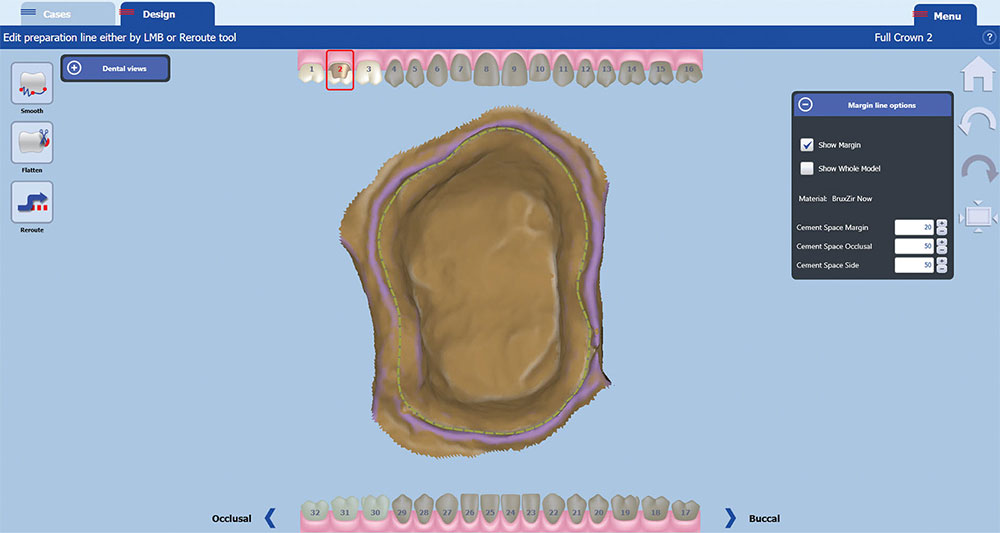

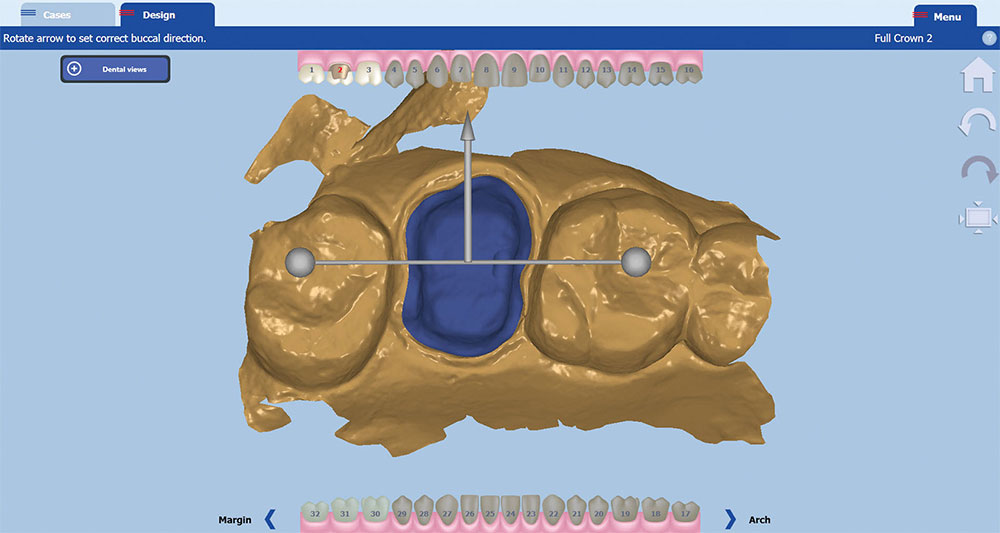

Photo Essay: Making Clear-Cut Cases Even Simpler with In-Office BruxZir® Solid Zirconia

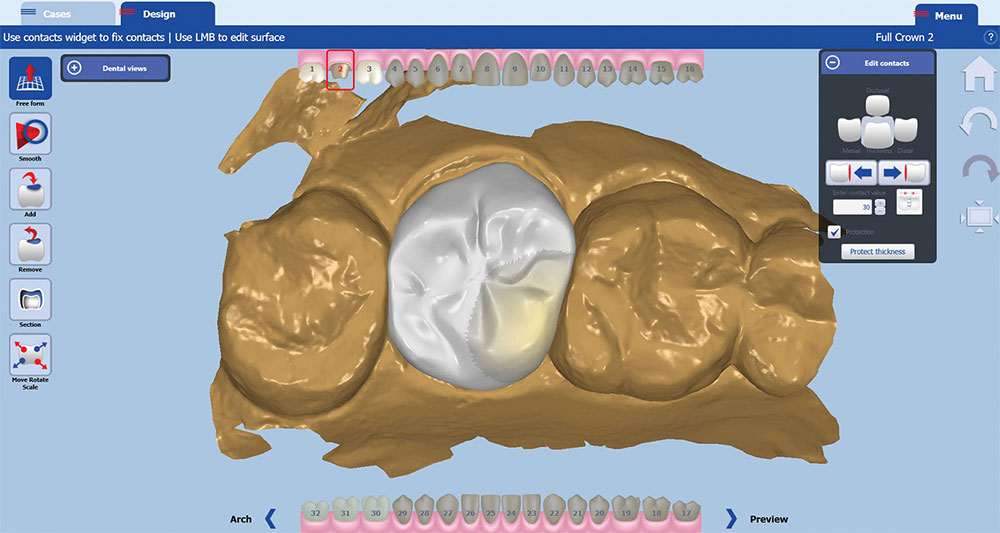

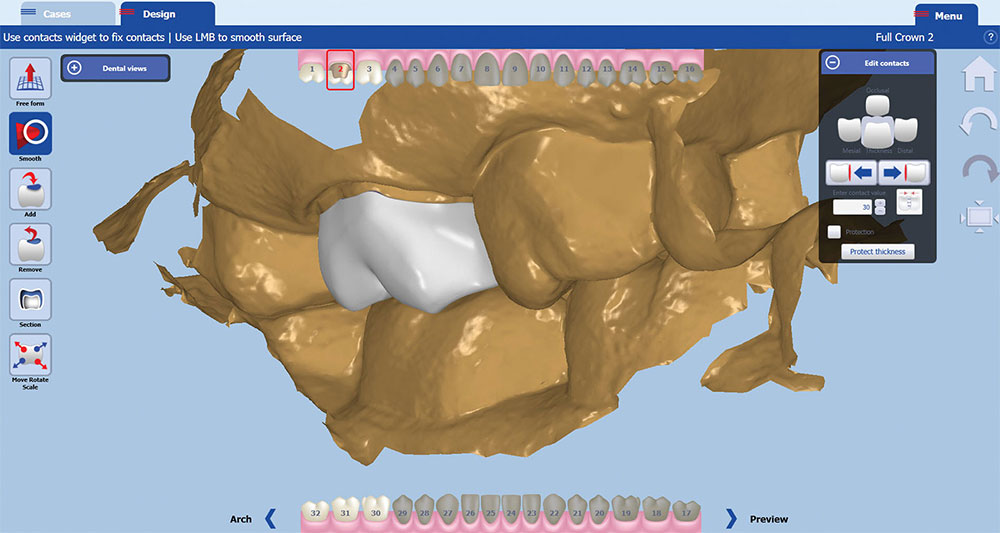

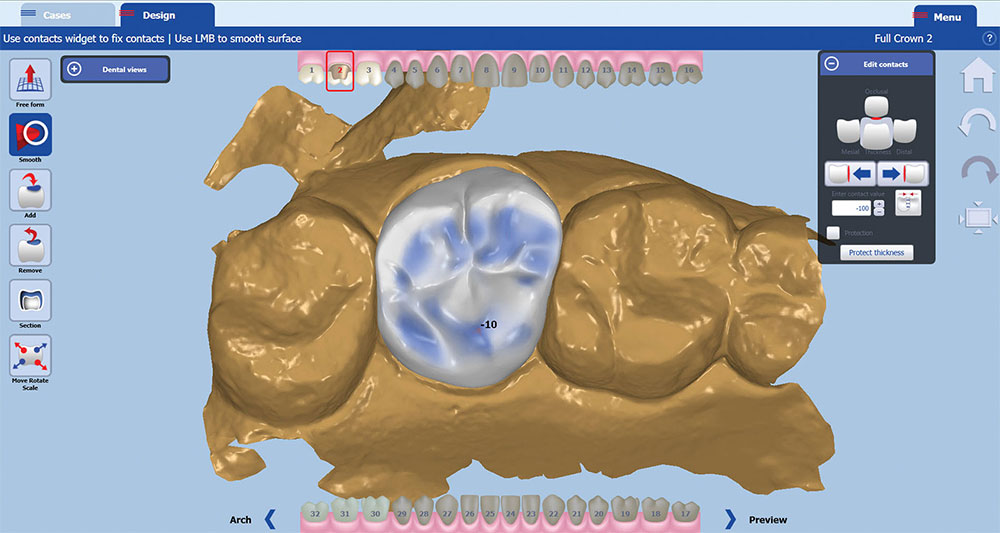

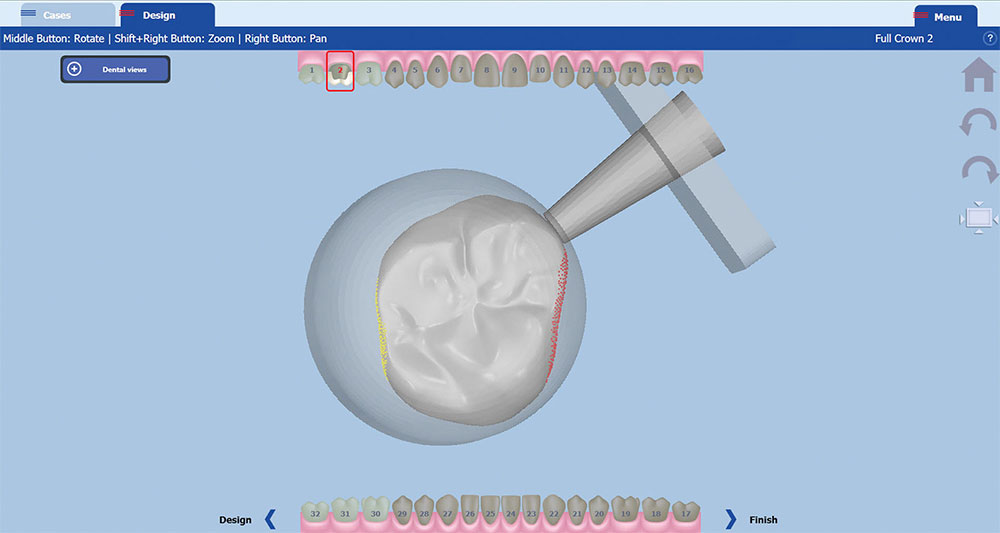

Clinicians who have embraced chairside CAD/CAM are truly empowered; they’re suitably able to deliver required treatment on a timetable that is favorable to the patient. Though the technology is not yet poised to eliminate all collaboration between dentists and the laboratory, cases that only require the restoration of a single posterior crown are ideally suited to chairside manufacturing. These simple bread-and-butter cases represent a significant opportunity for clinicians to differentiate their patients’ chair-time experiences from those provided at other offices; and now that recent advancements have placed some of the most clinically vetted materials chairside in ready-to-mill block form, they can do so without sacrificing quality of care. Practitioners can prepare for and deliver their tried-and-true material of choice in a single appointment.