New Innovations in Chairside Milling of Solid Zirconia Crowns

Once considered a niche service, in-office milling is now a familiar concept for practitioners, as the ability to effectively restore patients’ teeth in just one simple office visit represents the quintessential standard of care for straightforward single-unit posterior cases. With the adoption rate of digital impression technology continuing to climb, the introduction of lower cost and open-architecture digital impression scanners and milling units is allowing dentists to more readily implement a digital workflow into their practice.1 One of the significant impediments to this technology, however, has derived from the milling block materials available for same-day restorations. The milling blocks typically come in a “green” state and require sintering (a.k.a. baking), a time-consuming, technique-sensitive process in which the material undergoes a heat treatment to achieve optimal strength.

BruxZir® NOW milling blocks, which are made from high-strength post-sintered solid zirconia, take approximately 45–55 minutes to mill and require no staining or glazing. By using the innovative, pre-shaded BruxZir NOW blocks in concert with the TS150™ in-office mill (IOS Technologies, Inc.; San Diego, Calif.), restorations can be designed and fabricated in about an hour in the dental office, then delivered to the patient immediately, affording valuable time savings for doctors and patients alike. Additionally, crowns created through this workflow exhibit flexural strengths of more than 800 MPa, providing exceptional durability that’s designed to serve patients for years to come.

System Specifics

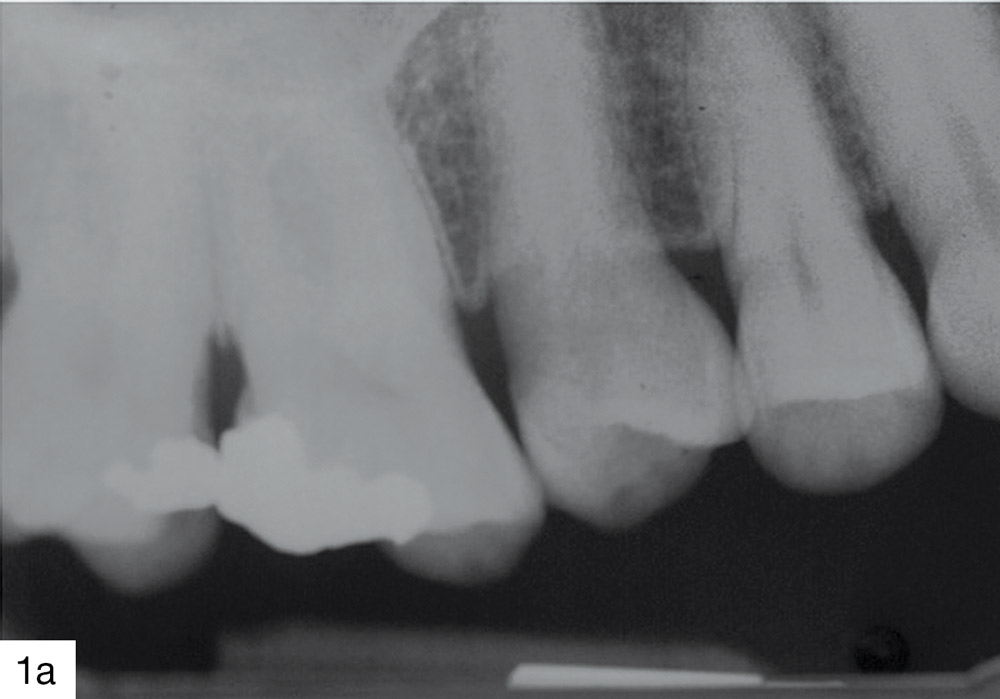

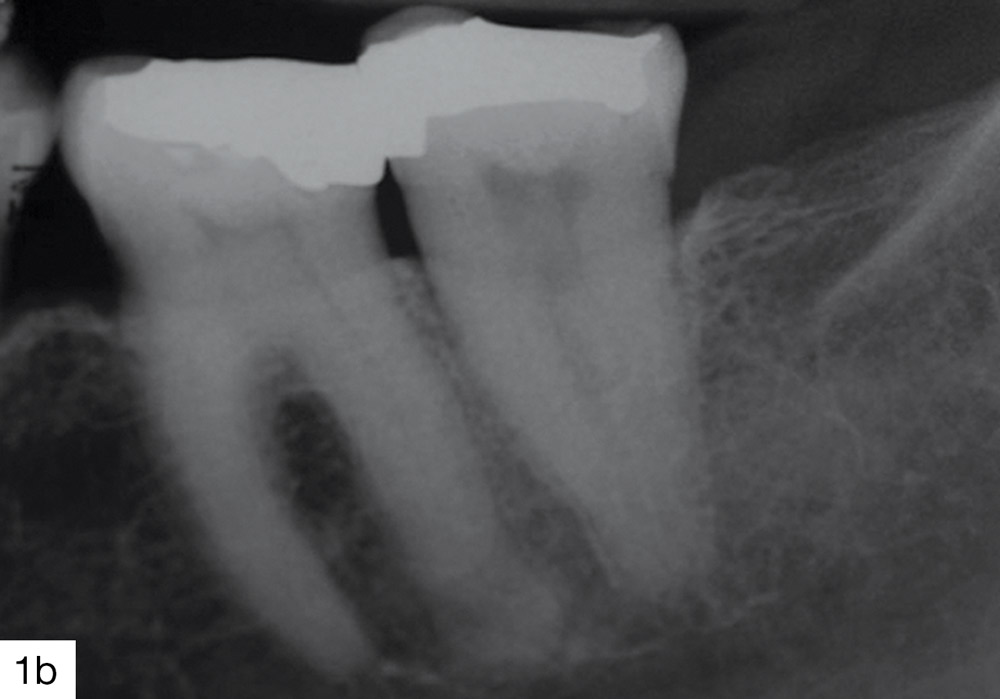

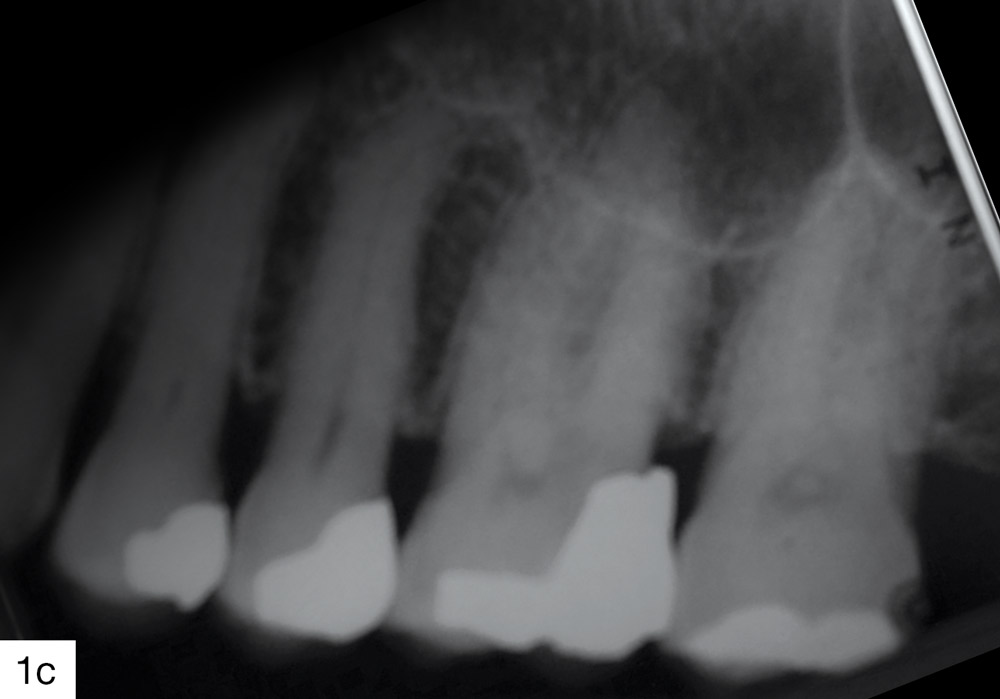

The protocol for in-office milling with BruxZir NOW begins with the doctor identifying that the patient requires this type of restoration, which is ideally indicated for single-unit posterior cases such as molar and premolar crowns (Figs. 1a–1c). Requirements allow for patients to keep more of their existing dentition through conservative preparation, including a manufacturer recommendation of 0.7 mm of occlusal reduction to produce optimal results, or only 0.5 mm in ideal situations. This is much less than the traditional posterior ceramic reduction, which requires up to 2.0 mm.

To get started, clinicians prepare and, using an intraoral scanning device like the iTero® Element Intraoral Scanner (Align Technology, Inc.; San Jose, Calif.), scan the tooth. For most proficient doctors, it takes approximately 2–5 minutes to scan an entire arch, and it can be faster to capture a single-unit posterior case because often only a scan of the treatment area is necessary.

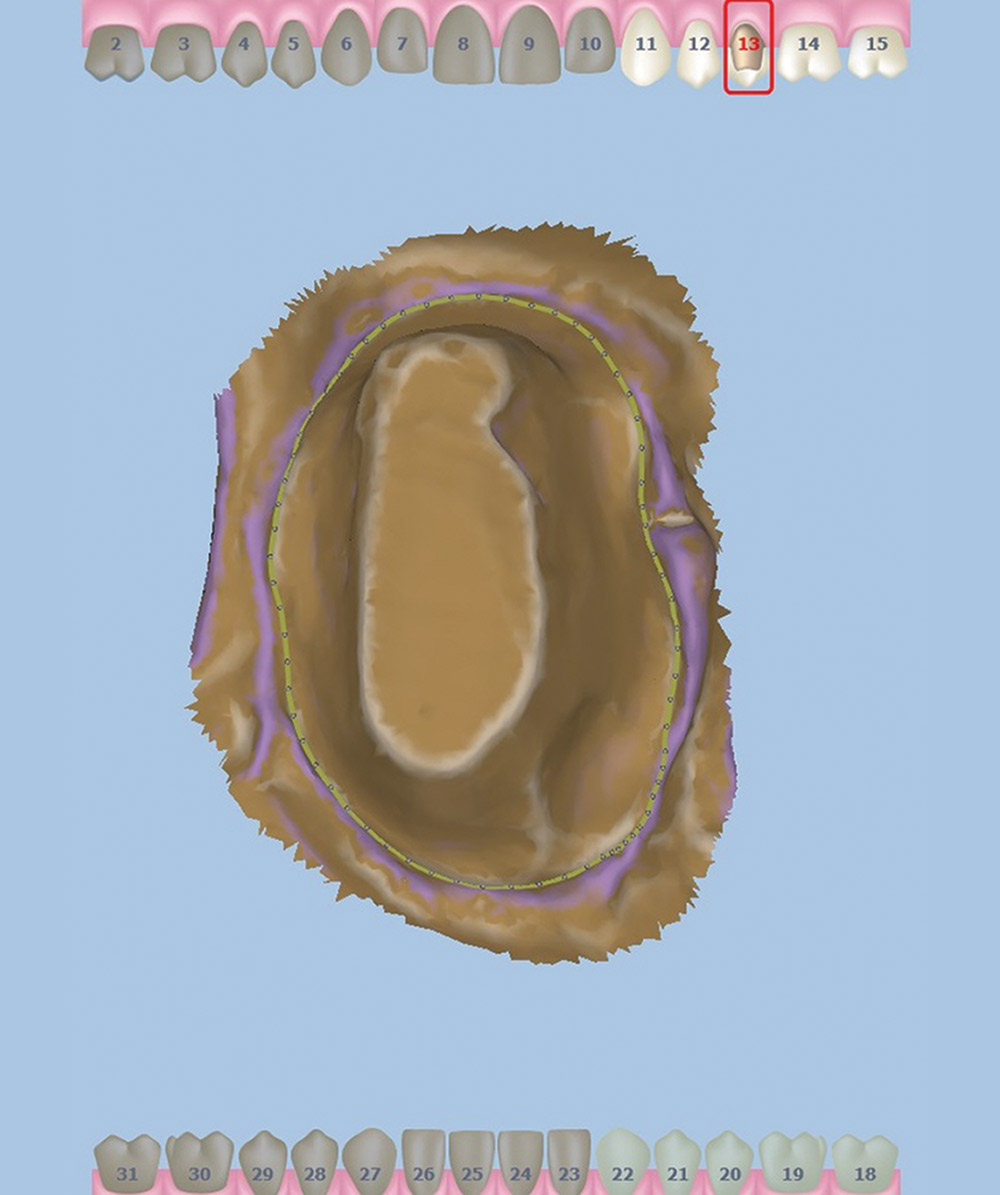

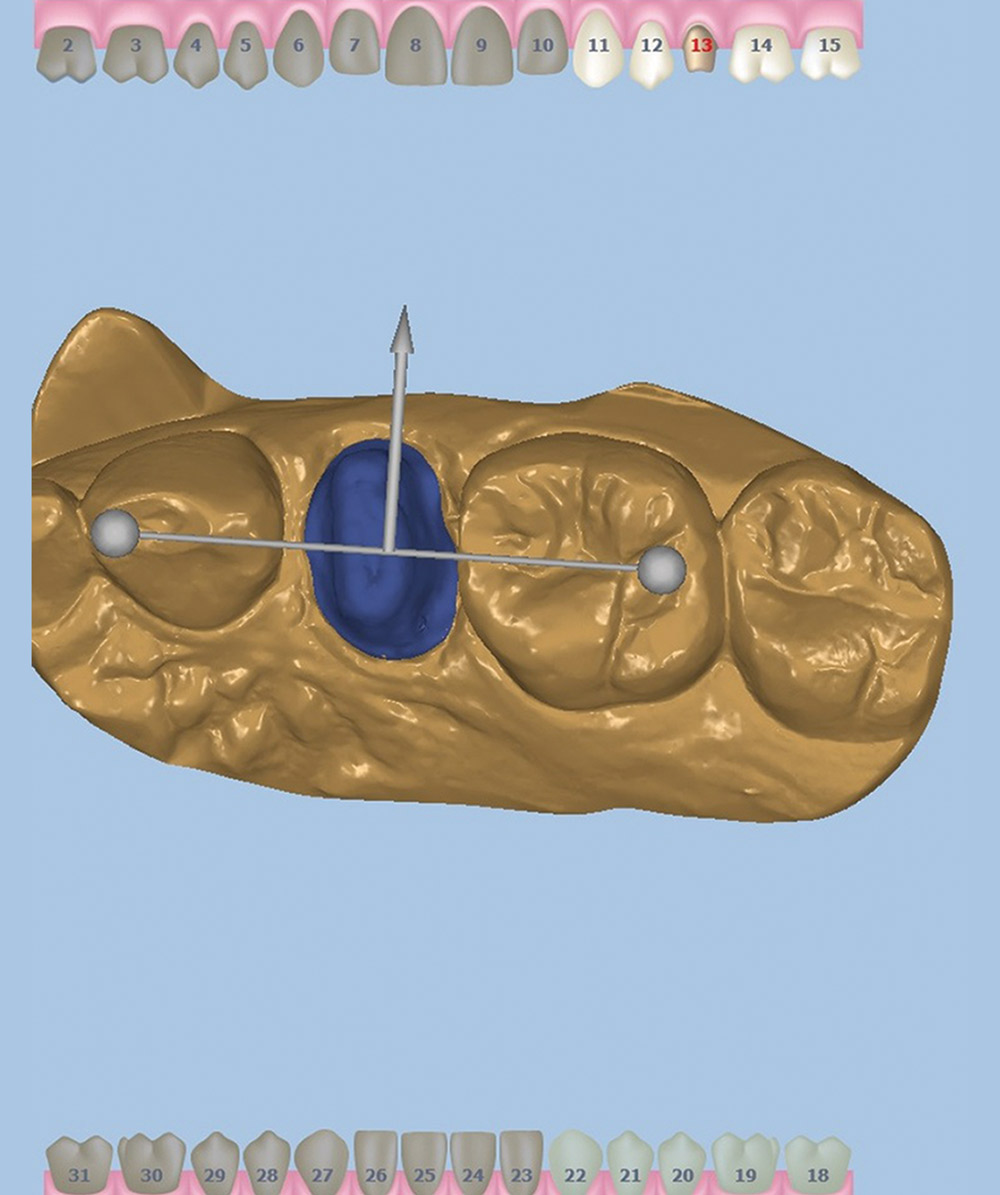

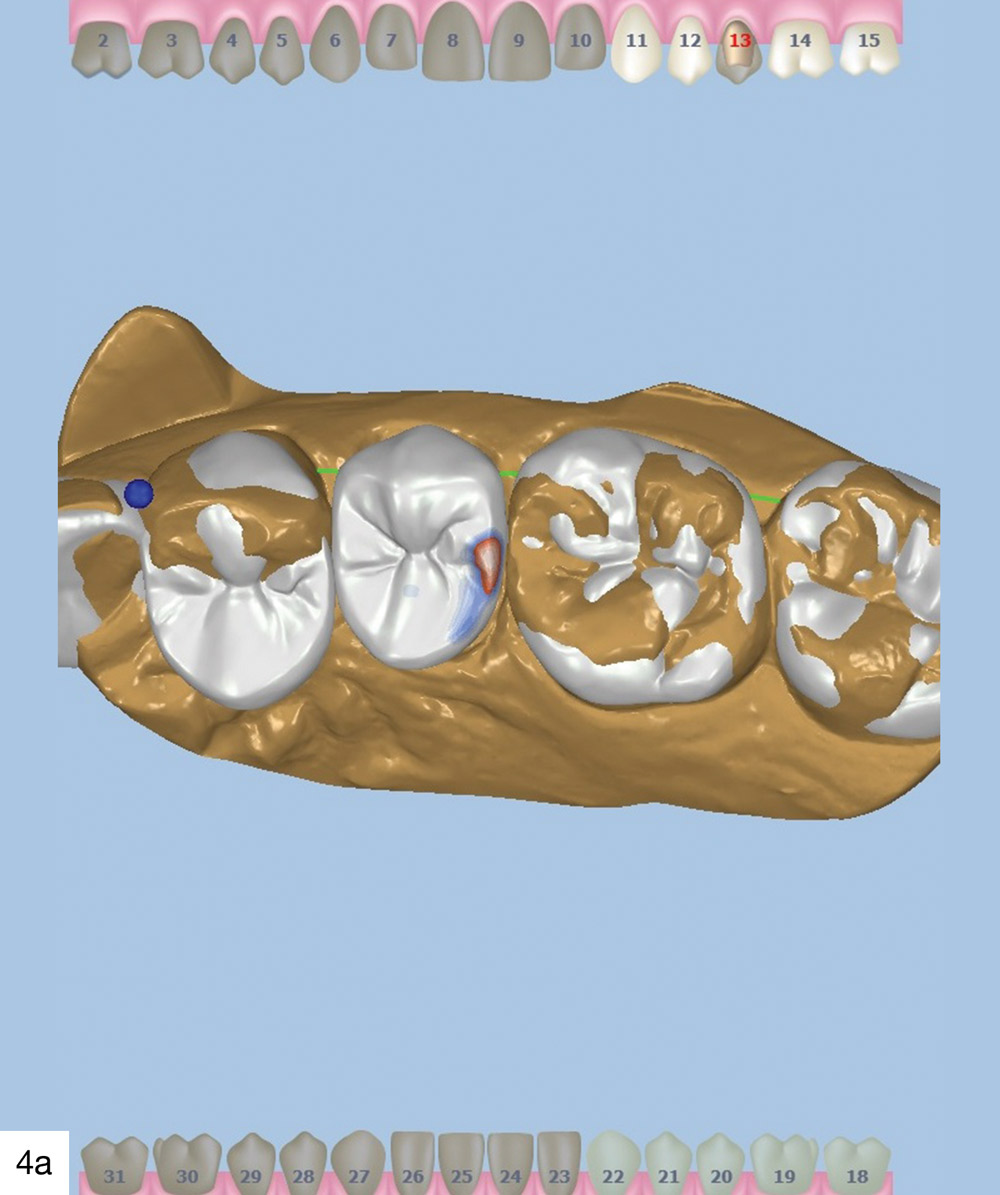

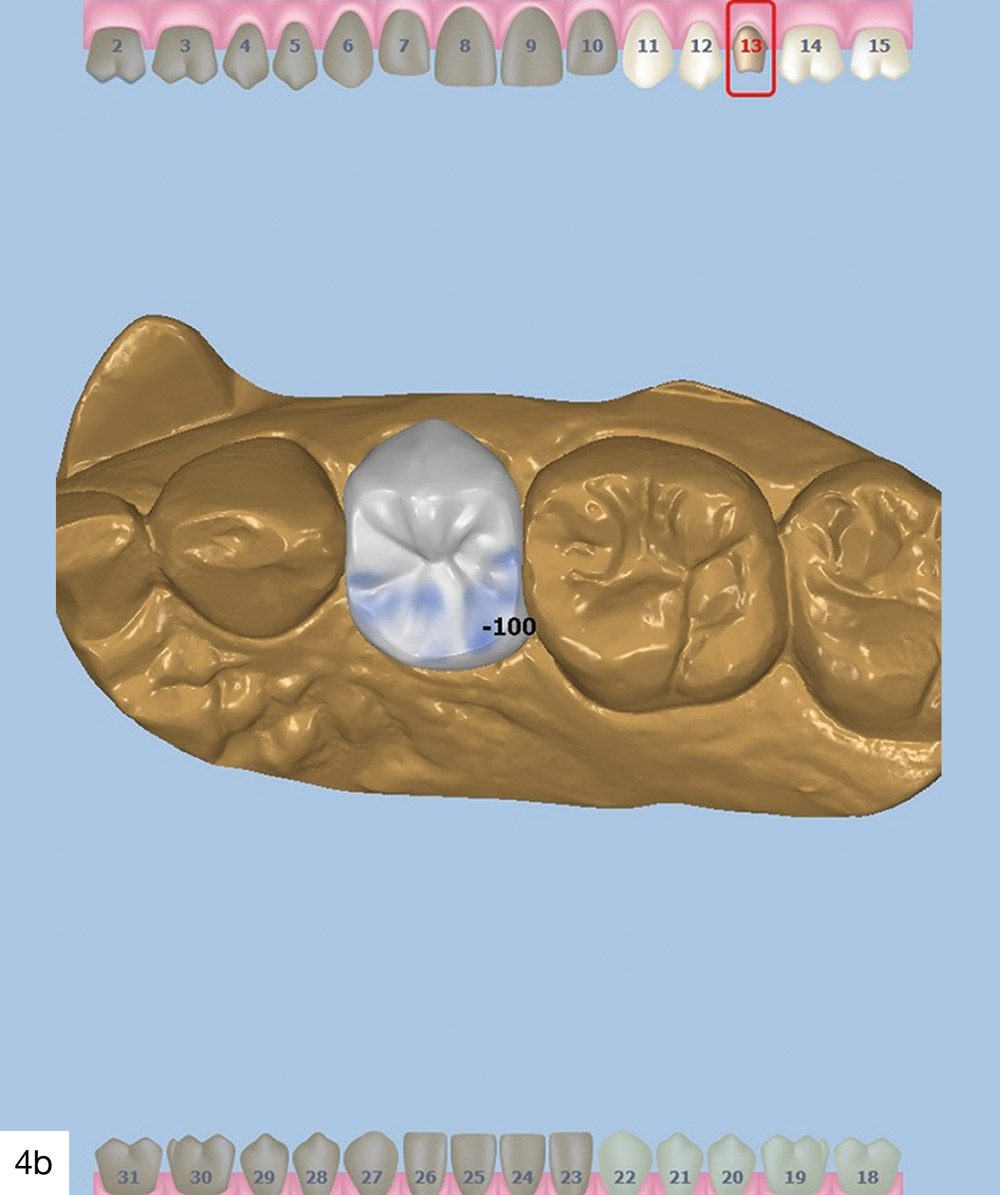

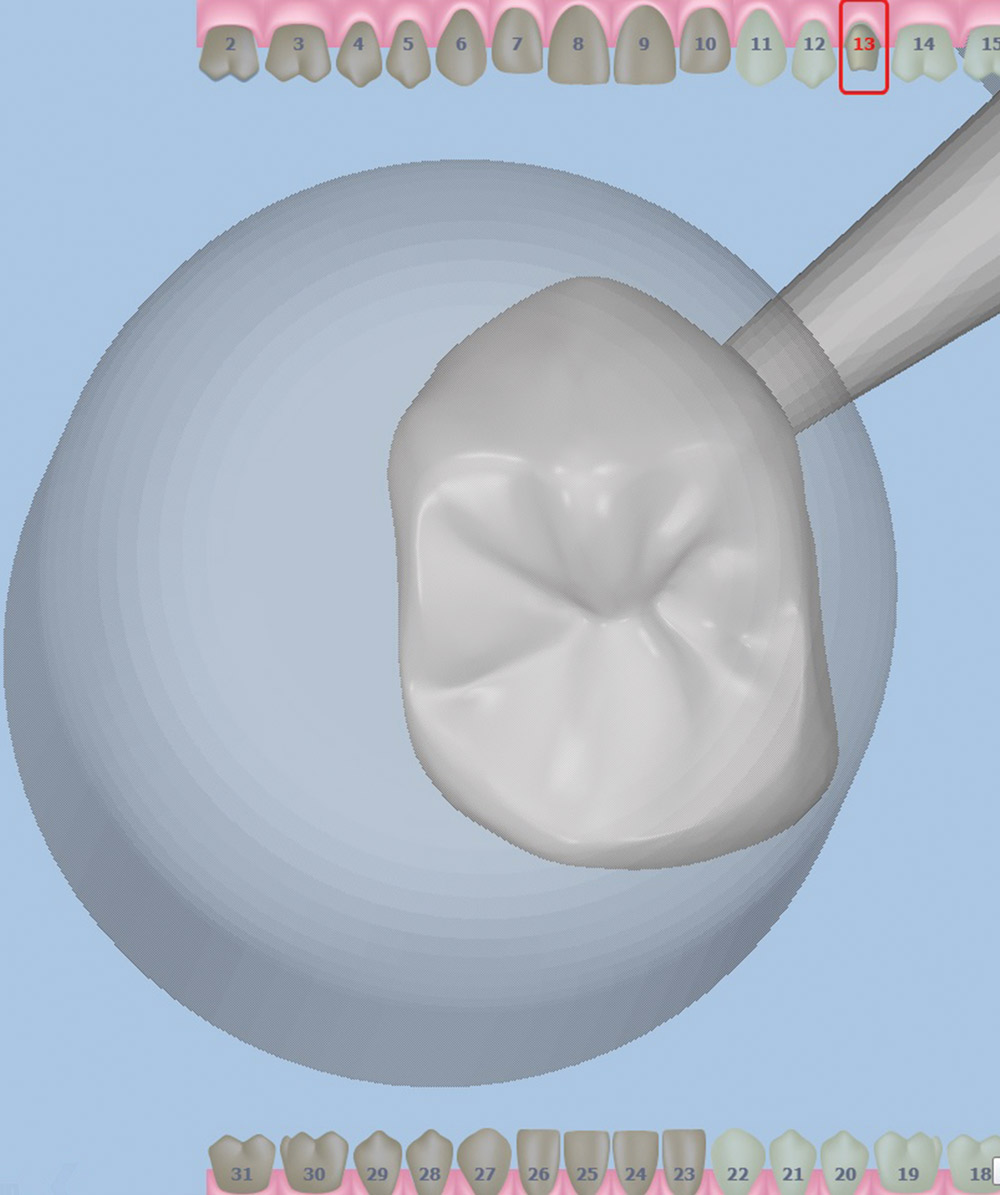

The scanned image is transmitted to the workstation, which is a dedicated computer for the TS150 chairside mill. Through a Wi-Fi connection, the patient’s name appears on the screen and the clinician is walked through simple steps to create the setup. At the workstation, highly intuitive IOS FastDesign™ software (IOS Technologies, Inc.) quickly and accurately proposes designs based on the tooth being restored. Any necessary adjustments can be made on the screen, such as shape modifications to fit the occlusion and position alterations relative to adjacent and opposing dentition. Margin marking is also made easy with tools for magnification and removal of soft tissue and other interferences, as well as detailed deconstructive views such as a cross-section graph and prep inversion (Fig. 2). Similarly, there are a multitude of crown design tools, including those to adjust occlusal morphology, identify areas of insufficient material thickness, add or reduce material to rectify those areas, smooth and shape surfaces, rotate the crown, adjust occlusal and interproximal contacts, and many more (Figs. 3–4b). The intuitive tools require little effort to master, and software implementation can be delegated to staff with minimal training (Fig. 5).

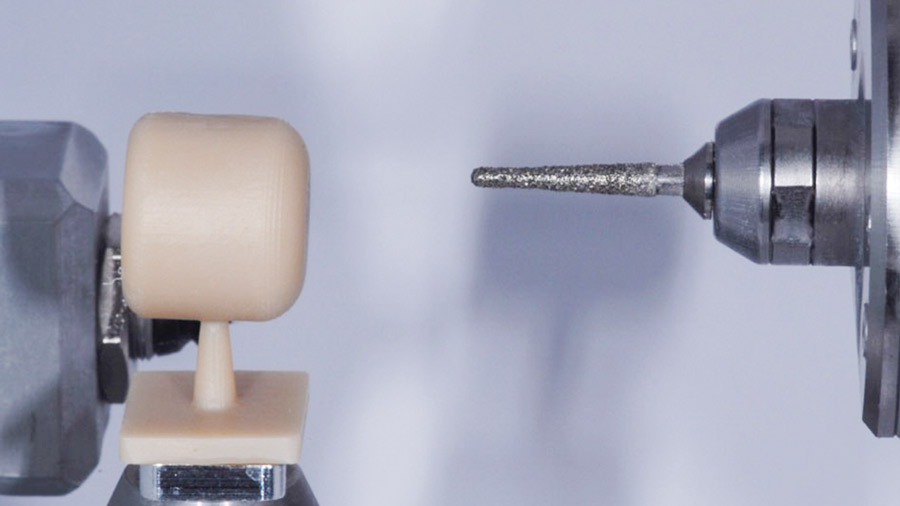

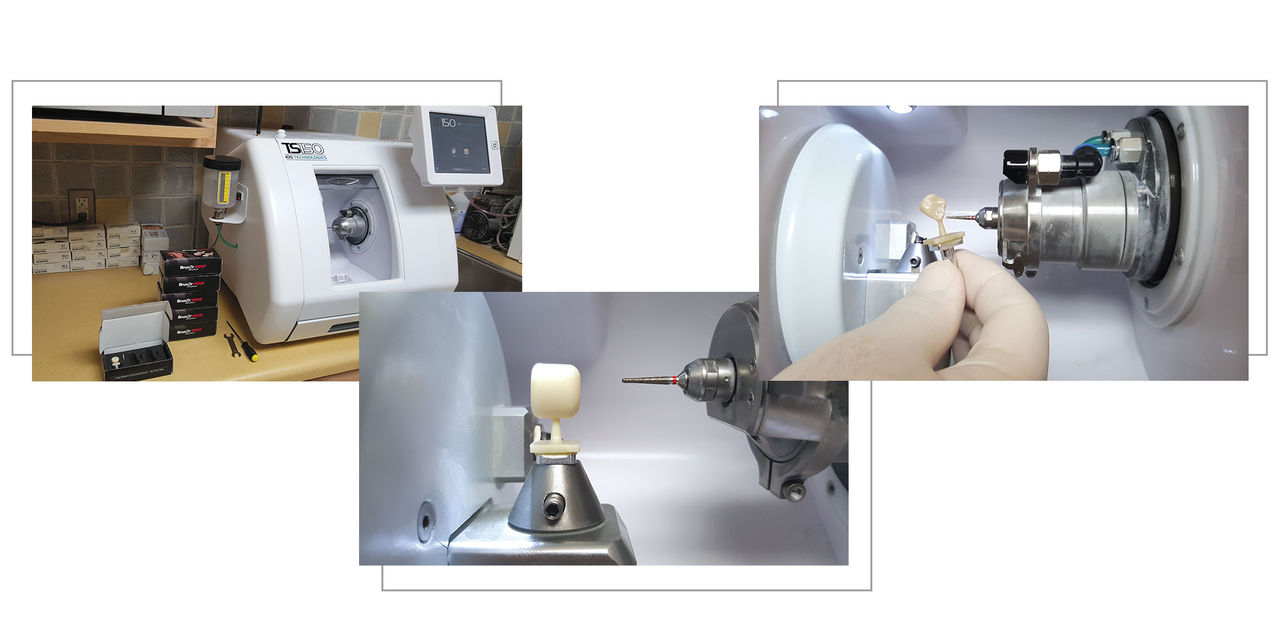

After the design is approved by the doctor, the design information is sent wirelessly to the TS150 chairside mill, where the clinician readies the system for fabrication by inserting the BruxZir NOW block and a purpose-made zirconia bur (Fig. 6). The fully automated unit reads out the time it will take for the restoration to be completed, and the operator can confidently walk away for the allotted time. At that point, the patient may step into the waiting room, which opens up the chair for the next appointment (Figs. 7a, 7b).

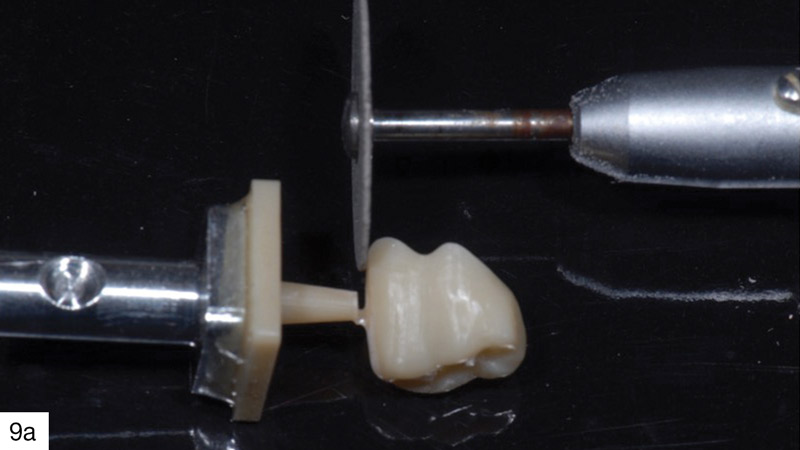

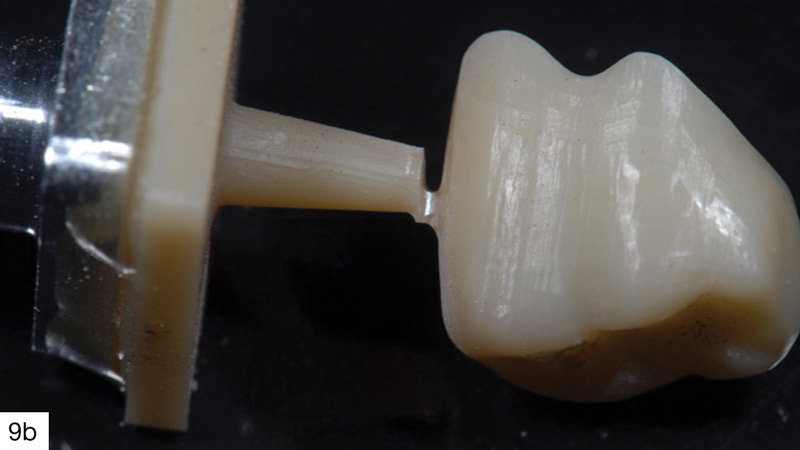

After milling is complete, the crown is removed from the machine (Figs. 8a, 8b). The clinician uses a high-speed diamond or carbonium disc to cut the sprue at its narrowest point, as close as possible to the restoration (Figs. 9a, 9b). Then, user-friendly polishing tools such as those found in the BruxZir Adjustment & Polishing Kit (Glidewell Direct; Irvine, Calif.) aid in polishing the crown. This simple procedure takes only a few minutes and creates a highly esthetic luster (Figs. 10a–10c).

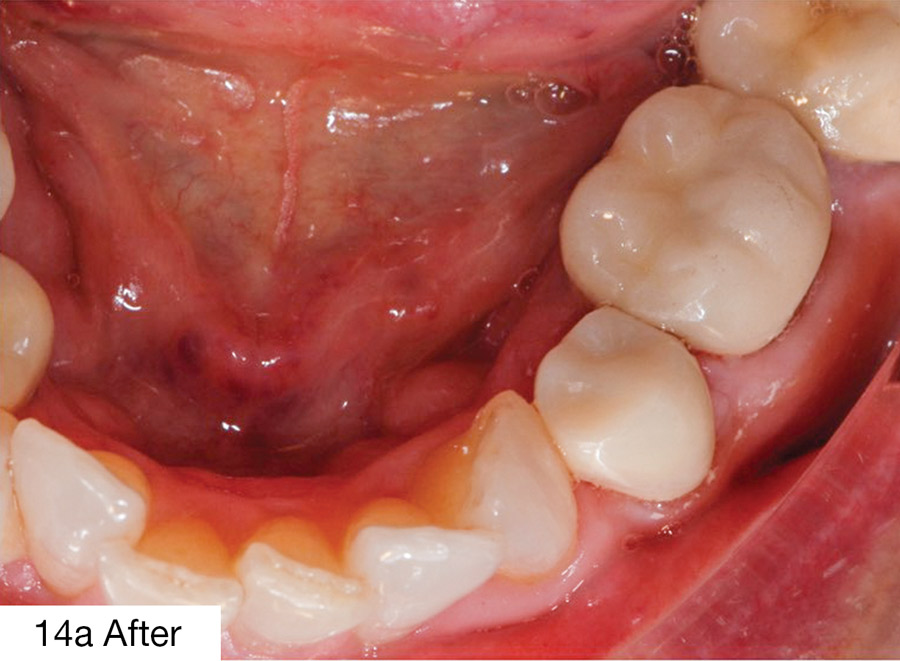

Following the sprue removal and polishing step (Figs. 11a–11c), the crown is tried in the mouth. Although the occlusion and contacts may be adjusted, it is typical for minimal or no adjustment to be required. After fit verification, the BruxZir NOW restoration is cemented to the tooth using a luting cement such as Ceramir® Crown & Bridge (Doxa Dental; Chicago, Ill.). The final delivery is straightforward and can be performed with ease (Figs. 12a, 12b).

Figures 4a, 4b: Crown proposals are generated to aid in the creation of a functional, esthetic restoration. An automatic crown design provided from a library (4a) can be easily moved and altered in all dimensions (4b).

Conclusion

Ideal for single-unit posterior cases, the BruxZir NOW system presents clinicians with cutting-edge technology for an in-office delivery system. In the past, clinicians had limited in-office methods for treating the posterior in patients with issues of parafunctional activity, abfractions in their teeth, or esthetic demands that required matching zirconia restorations to adjacent teeth. Now, a chairside machine can mill a fully sintered zirconia block to obtain the high flexural strength required for the posterior region. And because the blocks require no oven wait, crowns can be designed, milled and readied for placement in about an hour. Doctors are already familiar with chairside milling, so there is typically little to no learning curve with the user-friendly system. Generally, patients are not accustomed to the concept of same-day dentistry for a crown, so along with satisfaction at the esthetics and fit of the crown itself, there is a “wow factor” at the speedy turnaround time for treatment. While clinicians have successfully outsourced zirconia crowns to the lab in the past, performing the procedure chairside on demand allows for the ultimate control over the case. Additionally, the well-defined, precision fit delivered by these monolithic zirconia crowns contributes to patient satisfaction, an invaluable factor that builds untold long-term value to the practice (Figs. 13c–14c). Providing numerous benefits, the BruxZir NOW system can be readily incorporated into virtually any GP practice.

References

- ^Johnson P, Paulhamus C. Economic milepost: the rise in competition. Inside Dent. Technol. 2014 Dec;5(12) [cited 2016 Feb 18]. Available from: https://www.dentalaegis.com/idt/2014/12/Trends-in-Dentistry.