BruxZir® Full-Strength vs. BruxZir Anterior – Choosing Between Transformation Toughening and Light Transmission

In June 2009, Glidewell Laboratories released BruxZir® Solid Zirconia to clinicians in the United States, setting off a transformational shift within the industry and providing new and stronger esthetic treatment options. As dentists nationwide adopted the material into their practices, they discovered many additional indications for the material. Later, in March 2015, Glidewell Laboratories released BruxZir Anterior, a more esthetic, translucent version of zirconia that shared many similarities with the original BruxZir Solid Zirconia.

The purpose of this article is to clarify the scientific difference between BruxZir Anterior and BruxZir Full-Strength (originally named “BruxZir Solid Zirconia”), and to highlight the intricacies of their manufacturing processes. While both formulations are standouts in their respective categories, it is of importance that clinicians understand the materials and the specific indications for each.

Zirconia Powders

Material scientists and engineers across many industries have looked to zirconia (ZrO2) for its beneficial properties, which include a high melting point, superb strength and significant fracture toughness. Natural zirconia exists most commonly in the form of the mineral baddeleyite. In its pure form, the shape and structure of the individual crystals of zirconia exist in a specific crystalline phase at room temperature. Upon heating, that phase of zirconia changes twice as it reaches higher and higher temperatures, with each phase transformation accompanied by a volume change. Upon cooling, the phase transformation sequence reverses and leads to volume change-induced stresses, which are significant enough to cause zirconia structures to crack. That is to say, pure zirconia experiences phase transformations that lead to volume shifts which make the material in that form unsuitable for dental, medical and engineering uses.

To prevent these detrimental phase shifts, zirconia is blended (i.e., doped or stabilized) with other oxides so that the phases typically expressed only at higher temperatures become stable at room temperature. Commonly used dopants are yttrium oxide (yttria), calcium oxide, samarium oxide, magnesium oxide, lanthanum oxide and cerium oxide.

Yttria is among the most common additives for zirconia stabilization because it offers a blend of mechanical properties. Yttria-stabilized zirconia results in a white-colored stabilized zirconia, which can then be further colored and stained for dental applications.

Two specific zirconia materials have been developed at Glidewell Laboratories, BruxZir Full-Strength and BruxZir Anterior, with the primary difference between the two being the amount of yttria used to stabilize each specific version. BruxZir Anterior (roughly 9 percent yttria by weight) has nearly double the amount compared to BruxZir Full-Strength (roughly 5 percent yttria by weight), offering different properties for the final dental restoration. From the earliest design steps, they have been crafted to achieve specific end goals. BruxZir Full-Strength is intended to be an all-ceramic with unbeatable strength and chip and fracture resistance; whereas BruxZir Anterior is made to have more lifelike esthetics and natural translucency along with great strength.

BruxZir Full-Strength Powder Processing and Manufacturing

BruxZir Full-Strength milling blanks, which are used in the fabrication of BruxZir Full-Strength restorations by Glidewell Laboratories and Authorized BruxZir Labs around the world, are manufactured via a colloidal process. In a brief overview, the colloidal processing concept involves controlling the relationship between the zirconia particles by suspending them in a liquid (typically water). This high level of control allows material scientists to impart specific qualities into the powder formulation; for example, by reducing the interparticle space, we can promote homogeneity and higher density. In BruxZir Full-Strength zirconia, homogeneity in the milling blank is a desirable characteristic because it leads to uniformity of esthetics and strength throughout the millable blank and thereby throughout the final restoration.

As part of the colloidal manipulation, the yttria-stabilized fine powder for BruxZir Full-Strength is mixed and milled, resulting in a superfine powder mix. In fact, BruxZir Full-Strength zirconia powder is over 100 times finer than the diameter of a human hair and over 10 times finer than the average suspended particles in the ambient air we breathe in on a daily basis.

The superfine zirconia powder is slip-casted into containers shaped for the desired milling blank, and the resulting cast blank is dried. Once dry, the blanks are partially fired in a bisque cycle to strengthen the blank for milling. At this stage, the milling blank can be used by a computer-controlled milling machine at Glidewell Laboratories, or an Authorized BruxZir Laboratory, to create a dental restoration.

BruxZir Anterior Powder Processing and Manufacturing

BruxZir Anterior milling blanks are made from powder that is composed of granules which are two times finer than the width of a human hair, and the granules are approximately 50 times larger than the granules used in BruxZir Full-Strength. These granules feel and flow like household laundry detergent, and are in fact processed with the same spray-drying method typically used to form laundry detergents.

The BruxZir Anterior granules, which have a higher presence of yttria, contain binding agents that allow the granules to be pressed into a die in the shape of the desired milling blank. The resulting milling blank is then sent through a bisque firing cycle that burns off the binder and strengthens the milling blank for use in a milling machine.

Crystal Phase

The specific physical properties of each BruxZir material are established by the composition of their respective powder formulations, with the sought-after qualities of each material present before the blank manufacturing process. The primary differentiating element is the amount of yttria within each version, setting the stage for the resulting materials to express distinct properties.

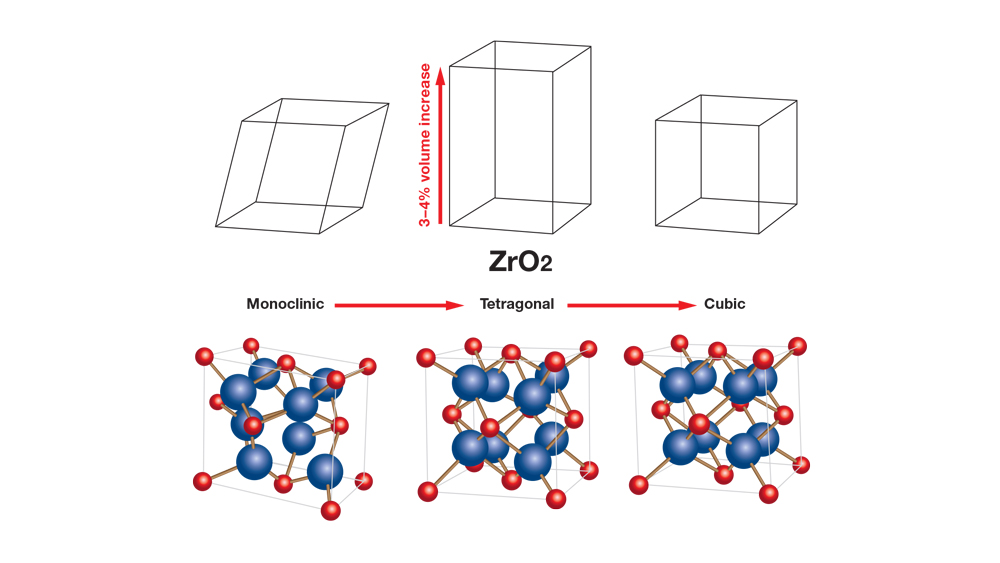

As introduced earlier, phase shifts occur when zirconia is heated and cooled. At the crystalline level (that is, the ordered arrangement of atoms and ions), the addition of yttria transforms the shape of the zirconia crystal (and hence the phase).

Mixes that surpass a certain threshold of yttria exhibit crystals that are uniformly symmetrical on all sides, like a cube, at room temperature. BruxZir Anterior zirconia crystals cross this threshold, and thus their crystals are predominantly cubic with equal length vectors on the x, y and z axes (Fig. 1).

BruxZir Full-Strength has less yttria in its formulation, resulting in zirconia crystals that are not in a fully symmetrical phase at room temperature. These tetragonal crystals are shaped like a rectangular cuboid. In a cuboid, the lengths of the x and y vectors are shorter than the length of the z vector (Fig. 1).

Figure 1: Zirconia crystals exhibit a phase change as they are heated and cooled. In dental zirconia, control over these phase changes is gained through the addition of yttria.

Additionally, there exists a third crystal phase for zirconia called monoclinic. Crystals in the monoclinic phase have unequal vector lengths on the x, y and z axes and have one oblique intersection (Fig. 1). In zirconia that is not treated with yttria, the material at room temperature exhibits these monoclinic crystals. As explained earlier, this pure phase of zirconia is not suitable for any medical or engineering use.

Thus, at ambient temperature the BruxZir Full-Strength formulation is composed primarily of cuboid-shaped crystals (and hence tetragonal phase) and BruxZir Anterior formulation is composed predominantly of cube-shaped crystals (and likewise cubic phase). For BruxZir Anterior, a small amount of tetragonal phase coexists with the cubic phase.

Translucency Due to Crystal Type and Phase Composition

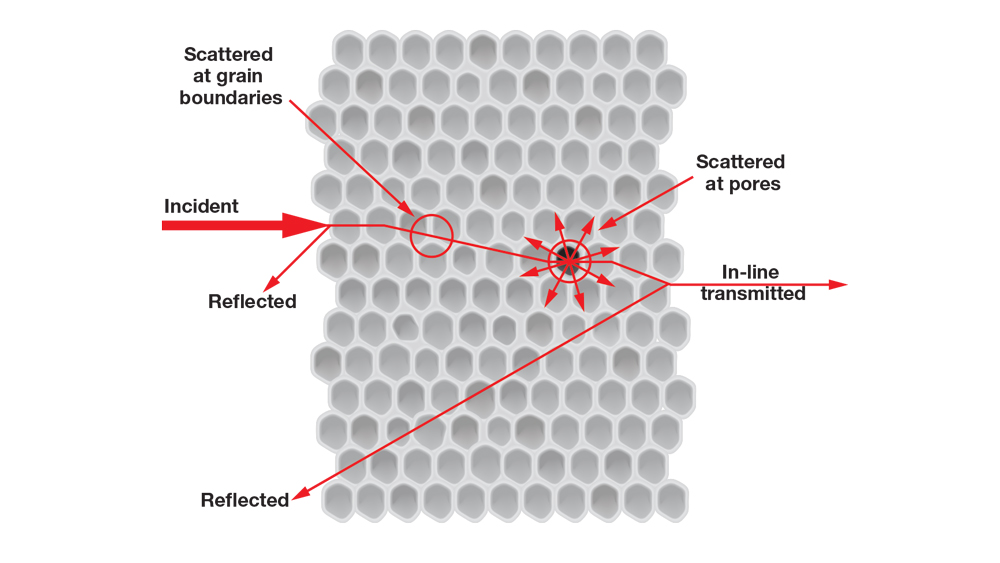

Single crystals group themselves into a grain, and then grains assemble themselves into a monolith. The faces of each grain are randomly oriented in the monolith, with the region where grains meet one another called grain boundaries.

When light is transmitted into the interior of a zirconia ceramic, it will experience interior reflection and refraction. This phenomenon is called scattering. This internal light scattering may result from the light’s interaction with several sources, including grain boundaries, pores, impurities, vacancies and defects (Fig. 2). Further, scattering of light will also occur when a light beam travels from an area that has crystals of one shape (e.g., cubic) to an area where the crystals are primarily of another shape (e.g., tetragonal). The different crystal shapes, or phases, have different refractive indices.

Figure 2: Diagram of how light interacts with a zirconia structure. Note how the light reflects, refracts and scatters as it interacts with several sources, including grain boundaries, phases, pores, impurities, vacancies and defects.

Tetragonal zirconia crystals are birefringent; which is to say, the index of refraction is expressed in different values in different crystallographic directions. A light travelling through a tetragonal zirconia crystal in one crystallographic direction will experience a different level of refraction than if it were to travel through that same crystal in a different crystallographic direction. This birefringence results in a change in the level of the refraction experienced by light when progressing from one grain to the next, because the adjacent grain will most likely not have the same crystallographic orientation. This causes both reflection, refraction and scattering at grain boundaries within a tetragonal zirconia monolith, leading to optical losses, and reductions in light transmittance and translucency as light moves through the monolith.

In contrast, zirconia with cubic crystals has an isotropic refractive index and is therefore able to transmit light more efficiently with less scattering.

In a sintered BruxZir Full-Strength restoration with tetragonal crystal phase, a typical grain size would be between 0.3–0.7 microns (300–700 nanometers). Each such grain consists of 600–1,400 tetragonal crystals. Each grain is randomly oriented in a different crystallographic direction within the sintered body and separated by a grain boundary. However, the crystals within each separate grain are oriented in the same pattern. A 1-mm–thick restoration would contain approximately 2,000 grains in the thickness direction. With each grain being randomly oriented and having different extents of light refraction and scattering as light progresses from one grain to the adjacent grain, the total optical scattering for an incoming light beam adds up.

In comparison, for BruxZir Anterior, a typical grain size would be between 1.0–1.5 microns. Each such grain consists of 2,000–3,000 cubic crystals. The cubic crystals have an isotropic refractive index (i.e., the same refractive index in all crystallographic directions). A 1-mm–thick restoration contains approximately 1,000 grains in the thickness direction that are all randomly oriented. Because the refractive index of each grain is the same, regardless of its random orientation, the optical scattering in BruxZir Anterior is substantially less than in BruxZir Full-Strength. Because there is less scattering experienced in BruxZir Anterior, more light is able to pass through the zirconia monolithic and, as a result, the BruxZir Anterior exhibits higher translucency, and thus better esthetics, than its lower-yttria counterpart.

The Benefit of BruxZir Full-Strength Zirconia

Having established that BruxZir Anterior is comprised of cube-shaped isotropic crystals that create a higher level of translucency for the crown, what benefit can be expected due to the rectangular cuboid (tetragonal) crystals of BruxZir Full-Strength?

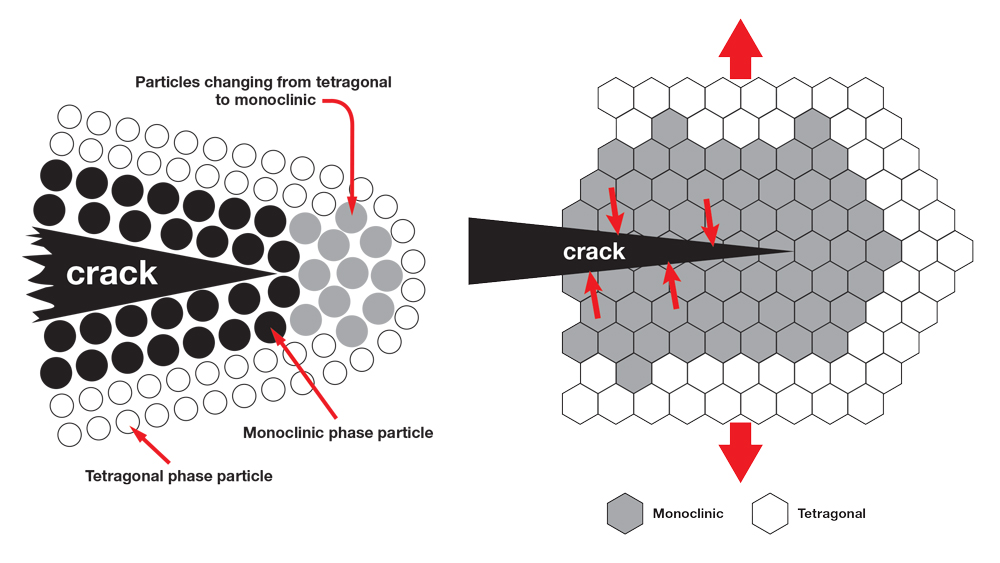

As discussed earlier, untreated (non-yttria) zirconia is most stable at ambient temperature in the monoclinic phase. The BruxZir Full-Strength formulation contains yttria; however, not to the threshold to establish cube-shaped crystals. The resultant crystals in BruxZir Full-Strength are rectangular cuboid shaped at room temperature, with a natural tendency to want to phase change to the more stable monoclinic crystals. This inclination to change from tetragonal to monoclinic is largely prevented by the presence of yttria; though fortuitously, this desire to phase change is not prevented entirely.

In a process unique to tetragonal zirconia, a toughening mechanism comes into play when a crack is encountered. When a stress-field at the tip of the crack is expressed on the rectangular cuboid (tetragonal) crystals, they will phase change to monoclinic crystals (i.e., their original preferred stable phase) and in the process expand in volume. This volume expansion occurring adjacent to the crack tip presses against the crack and arrests it. This mechanism is called transformation toughening (Fig. 3). Effectively, the progression of a crack is stopped because it triggers an expansion at the crystalline level of the zirconia material that seals the crack and counteracts that crack’s force.

Figure 3: The stress-field at the tip of the crack moving through a tetragonal zirconia structure causes the tetragonal crystals to transform to monoclinic crystals, with a resulting increase in volume that then presses against the crack and effectively stops the crack propagation.

This transformation toughening property means that when a crack is propagating through the BruxZir Full-Strength material, the stress at the tip of that crack is forcing a phase change around and ahead of it, which results in the forward movement of the crack being arrested. It is important to note that this is happening at a microscopic level and that clinicians shouldn’t expect visible cracks to heal themselves in front of the naked eye.

When a crack is propagating through the BruxZir Full-Strength material, the stress at the tip of that crack is forcing a phase change around and ahead of it, which results in the forward movement of the crack being arrested.

In addition to the class-leading flexural strength of BruxZir Full-Strength, the structural integrity of each crown is further protected by the process of transformation toughening. Microscopic cracks that occur in the material are stopped by the transformation toughening nature of tetragonal zirconia crystals.

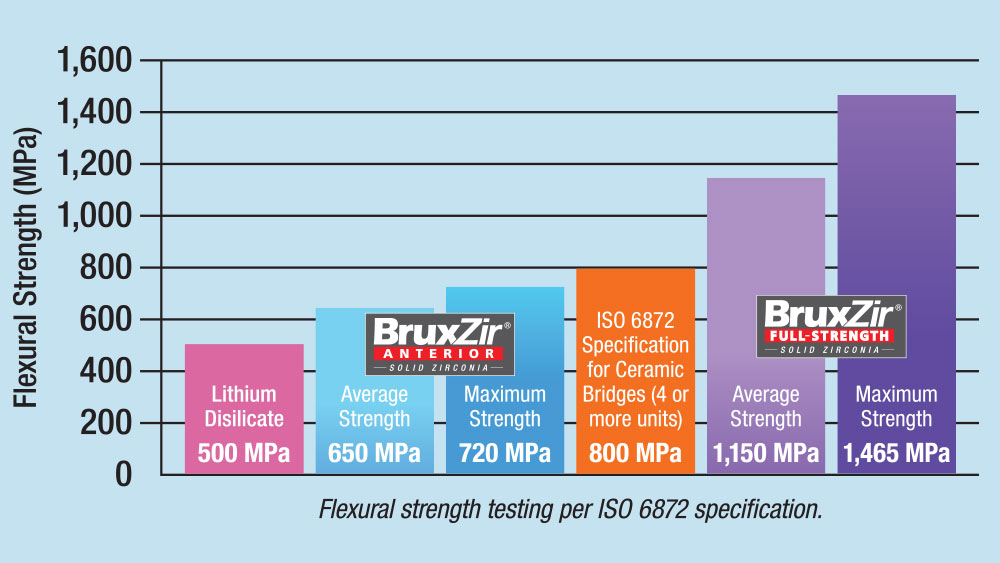

Choosing the Right Material for Your Case

Both BruxZir Full-Strength and BruxZir Anterior exhibit flexural strengths that are significantly above other tooth-colored dental restorative materials, including lithium disilicate, composite and feldspathic porcelain (Fig. 4). When choosing which of the two BruxZir materials to use, the selection should be based along these lines: lifelike translucency, high esthetics and good strength (BruxZir Anterior) versus fracture toughness, supreme strength and good esthetics (BruxZir Full-Strength).

Figure 4: This chart depicts the differences between the flexural strengths of the two zirconia versions of the BruxZir brand.

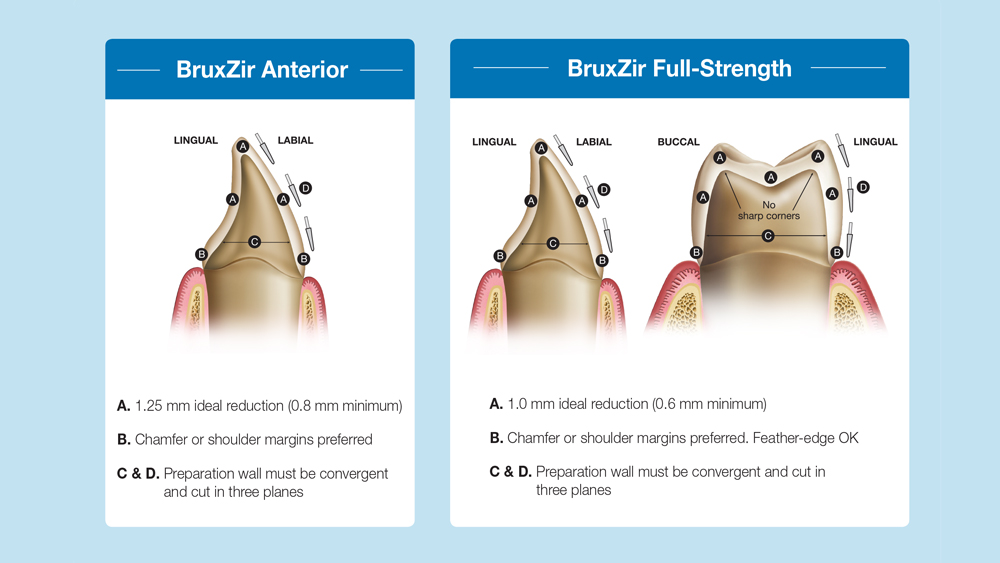

It is of paramount importance to note that the difference in strength between the two BruxZir materials warrants different intraoral preparations, with BruxZir Anterior requiring slightly more reduction than BruxZir Full-Strength (Fig. 5). Further, the lower strength of BruxZir Anterior in relation to BruxZir Full-Strength means that Anterior is not indicated for long-span bridges in the posterior. When compared to the breadth of restorative materials available to clinicians, BruxZir Anterior is still a high-strength material, though not quite as strong as BruxZir Full-Strength.

Figure 5: The manufacturer recommendations for preparations.

Conclusion

From the very beginning of each material’s manufacturing processes, BruxZir Full-Strength and BruxZir Anterior are not intended to be identical. The materials and their respective manufacturing processes are specifically engineered to achieve different goals. Clinicians who keep that in mind and follow the manufacturer specifications when employing each material will be rewarded with high-strength zirconia crowns specifically tailored for quality dentistry.