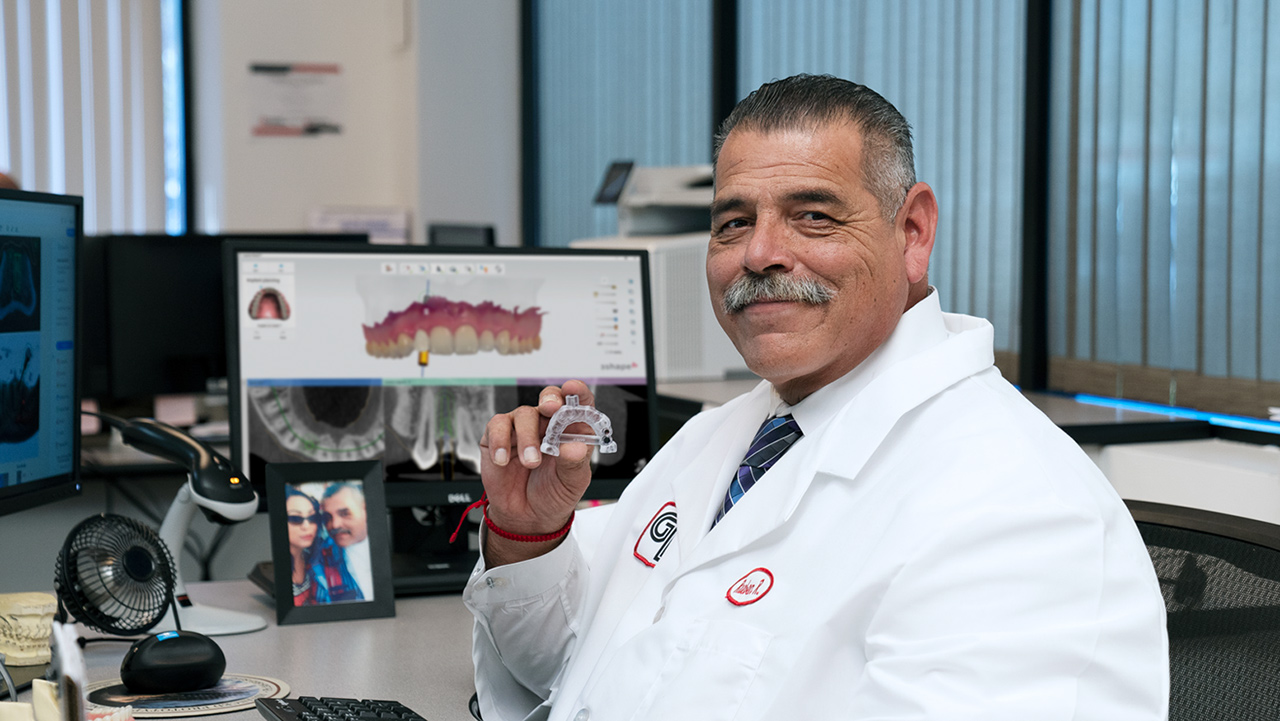

Romero also takes pride in the knowledgeable technical support his team provides to dentists and his team’s diligence in making sure the doctor signs off on every aspect of the treatment plan.

“The customer service that we have here really makes us stand apart from the competition. Every member of our team has been with us a long time and they understand the surgical procedure,” Romero said. “Of course, we leave it up to the doctors to make the final decision on the surgical plan, but we help them out every step of the way and make sure they understand how the implant position affects the prosthetic outcome.”

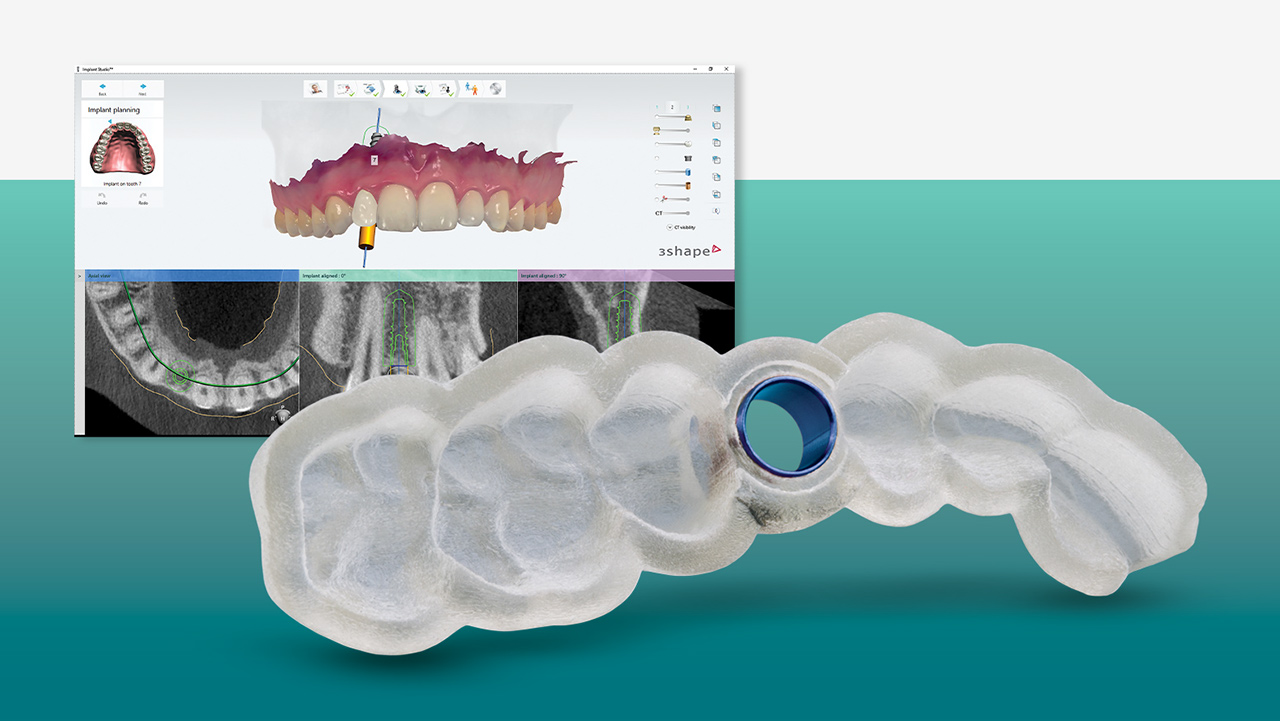

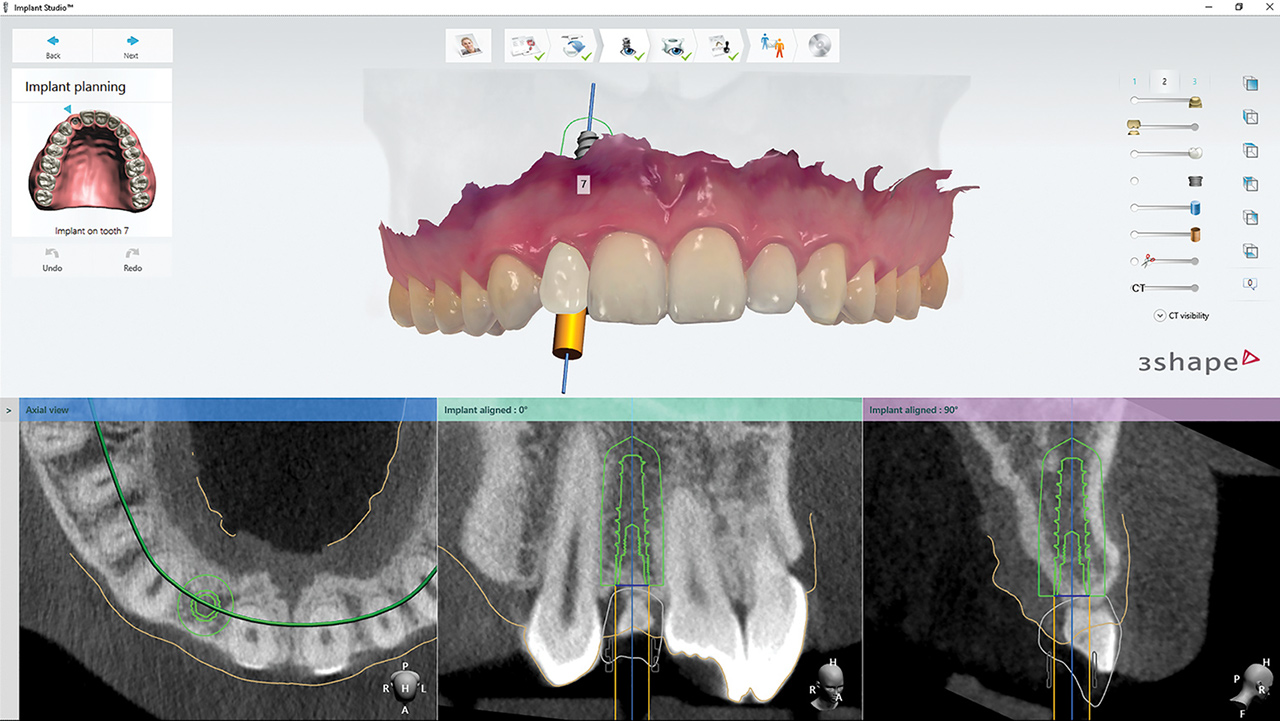

“The reports we send clinicians for approval are very accurate and detailed, and outline every consideration the dentists should know about, like if the bone density is questionable,” Romero added. “If the doctor declines a plan, we make the changes and send the report back for another look. We require the doctor’s explicit approval before we complete the plan. We’re a department that plans the cases for the doctors, but the doctor is the one who finalizes the approval.”

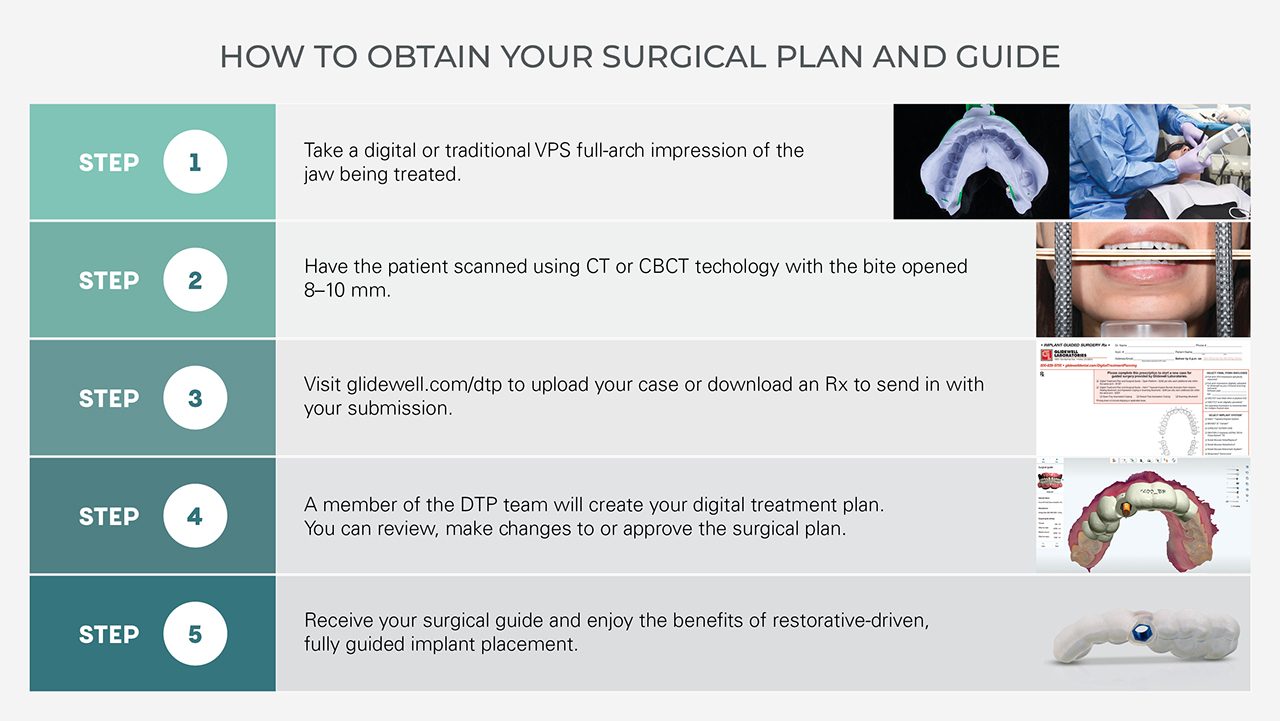

As both a manufacturer of implants and the biggest dental lab in the U.S., Glidewell offers unique advantages for dentists, including cost savings and a restorative-driven approach to implant dentistry — from treatment planning to final restoration. For example, the Hahn™ Tapered Implant System, which was developed by Glidewell in collaboration with implant pioneer Dr. Jack Hahn, includes a bundle package that helps significantly reduce the cost of treatment. For only $395, dentists receive a digital treatment plan, a surgical guide, a Hahn Tapered Implant, and a healing abutment or scan body. Additionally, Glidewell offers 20% off all restorations over Hahn implants, further lowering expenses for dentists.

Romero notes that this approach to treatment also simplifies inventory management for dental practices. “The Hahn Tapered Implant Bundle gives the doctor a sense of security because we send out exactly what’s needed to perform the surgery for each individual patient,” he said. “You don’t have to search around and find the correct sizes of components, the screws, and everything else you need to complete the surgical procedure. You won’t have a situation where you need a 3.5-mm-diameter implant and healing abutment, but you only have 5.0-mm-diameter components on hand. It’s one more thing you don’t have to worry about — in addition to having a slam-dunk surgical plan, you also don’t have to worry about your inventory.”