2201 Dupont Dr., Irvine, CA 92612

© 2025 Glidewell. All rights reserved.

800-854-7256 USA

Explore the key differences between crowns made with chairside mills and those produced with 3D printing technology.

In the rapidly evolving field of dentistry, the advent of digital technologies has significantly transformed how dental crowns are fabricated. Traditionally, dental labs were the sole creators of crowns, but now, dental practices can opt to mill crowns in-office or use 3D printing technology. Both methods offer distinct advantages which can impact the efficiency, cost, and quality of dental care. Here, we explore the pros and cons of each approach to help dental professionals and patients better understand their options.

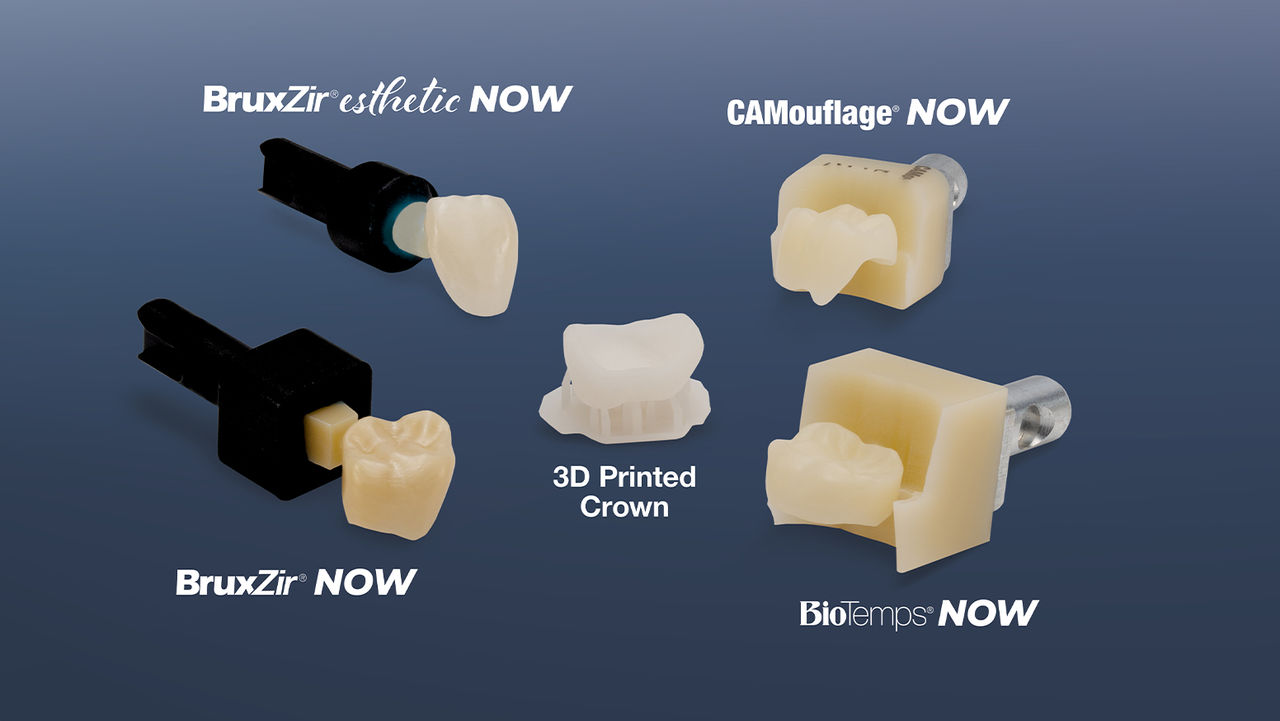

When comparing the material strength of crowns milled in-office to those made using a 3D printer, milled crowns exhibit superior durability and longevity. In-office milling machines like the fastmill.io™ In-Office Mill, use high-strength materials such as zirconia and glass ceramic, which are renowned for their excellent mechanical properties, wear resistance, biocompatibility, and esthetics. Simply put — they look and function like natural teeth. These milling materials can withstand significant biting forces and provide long-lasting restorations.

The fastmill.io offers compatibility with a wide range of materials, making it adaptable to various clinical needs and treatment scenarios. 3D printers and 3D printed crowns have a limited range of clinical applications.

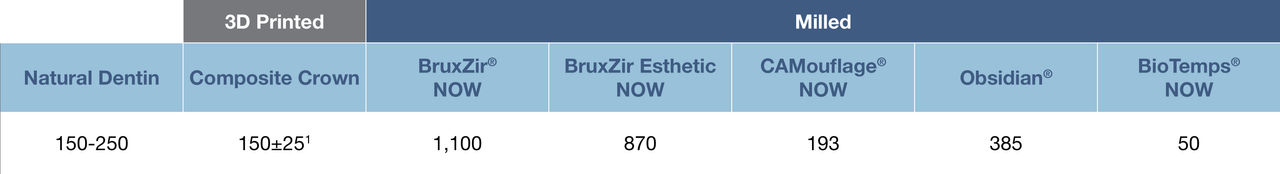

In contrast, while 3D printing technology has made significant strides in recent years, the materials used do not match the strength, esthetics, and wear resistance of milled zirconia or ceramic. 3D printed crowns are made from composite resin — a blend of ceramic and synthetic polymer. Consequently, 3D printed crowns may be more prone to wear and fracture over time, making them less ideal for situations where long-term durability is important. The chart below outlines the resistance levels of several leading materials.

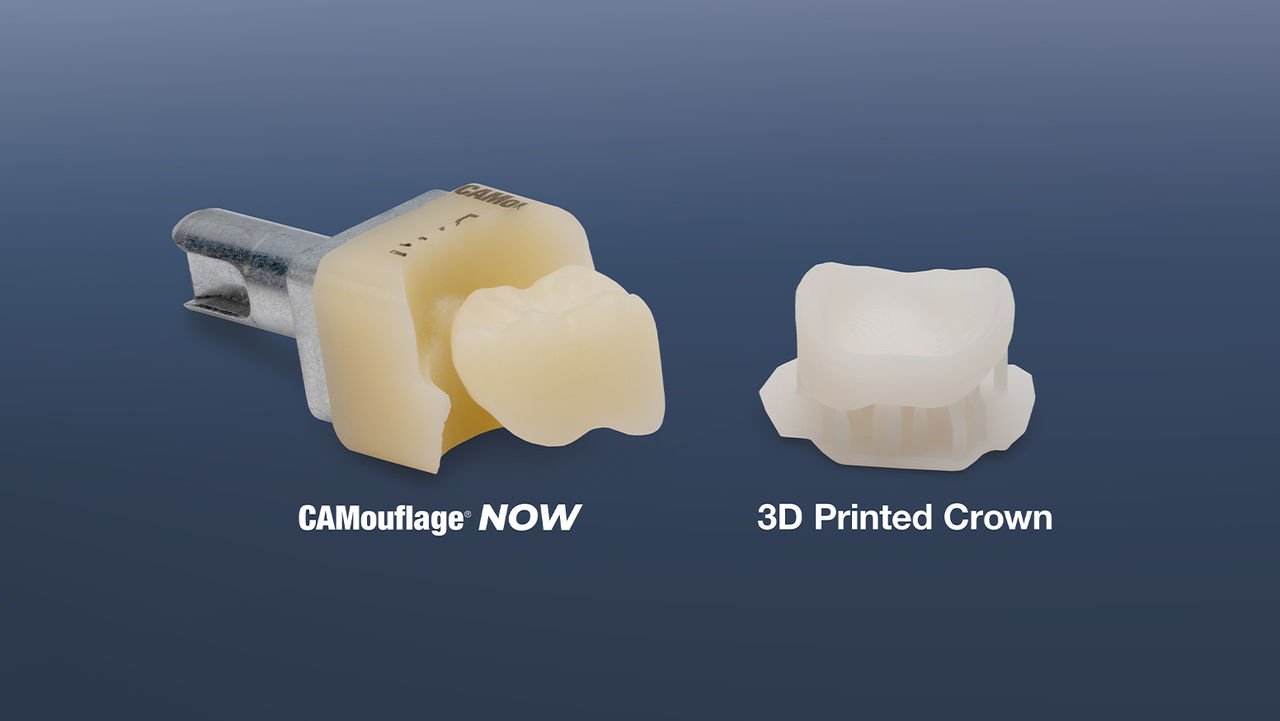

As shown above, there are a variety of mill-compatible materials that exceed the strength of a 3D printed crown. However, durability may not always be the most important factor when selecting which material to use. The speed, reliable bonding, and malleability of a resin-based composite material may take precedence in some situations. For a same-day composite solution with comparable results to a 3D printed crown, CAMouflage NOW offers a quick and versatile alternative. Designed for use with the fastmill.io In-Office Mill, this material is composed of a ceramic-filled nanohybrid resin composite material that works well for both permanent and temporary applications. With a flexural strength rating that still exceeds that of 3D printed crowns, doctors who prefer composite restorations will have a significant advantage by using an in-office mill.

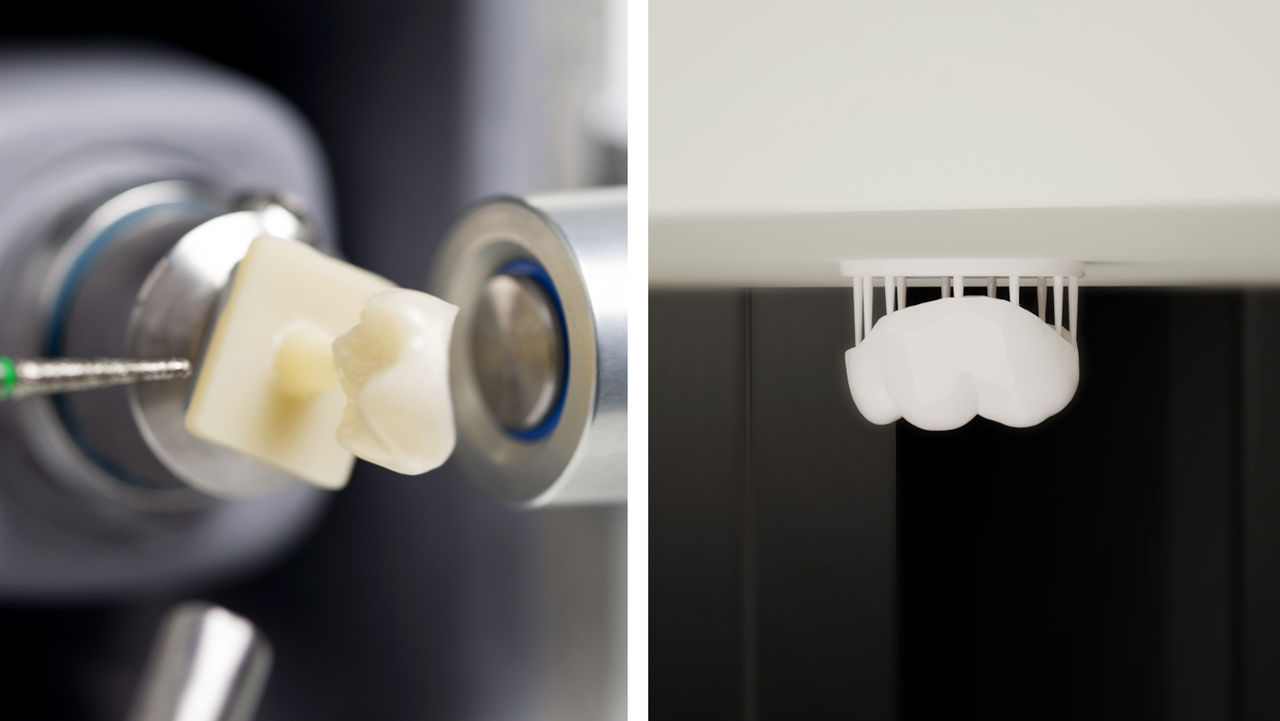

The image above shows a CAMouflage NOW crown made using a chairside mill, and a crown made using a 3D printer. As a versatile ceramic-filled nanohybrid resin composite with superior flexural strength, CAMouflage NOW is an ideal alternative to 3D printed crowns.

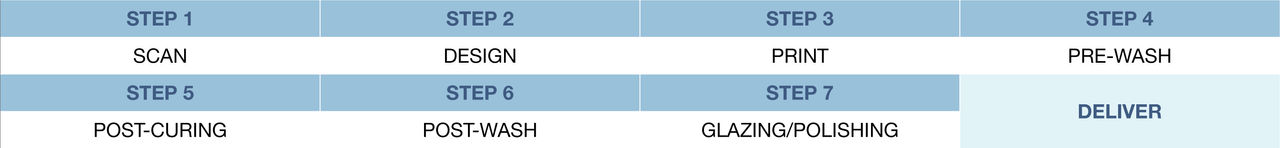

The digital workflow for fabricating an in-office milled crown versus a crown made using a dental 3D printer differs significantly in terms of steps and time involved.

For in-office milling, the process begins with a digital impression of the patient's tooth, which is then used to design the crown using CAD (computer-assisted design) software. The design is then sent to a milling machine that carves the crown from a solid block of material. CAMouflage NOW, for example, has a remarkably fast milling time of under ten minutes. With no oven stage required for post-processing, a CAMouflage NOW restoration can be delivered straight from the mill.

In contrast, the digital workflow for a 3D printed crown also starts with a digital impression and CAD design, but the design is sent to a 3D printer that builds the crown layer by layer from a resin material. While 3D printing certainly offers some convenience, the additional post-processing time and steps required can extend the overall production timeline, making it less ideal for same-day procedures.

Use the fastprint.io™ 3D Printing Solution to make clear, transparent appliances direct from the printer with minimal polishing needed.

While 3D printers may not deliver the ideal quality and resistance for a permanent restoration, they certainly have their place in the dental practice. Oral appliances, aligners, models, surgical guides and more can all be easily created chairside using a 3D printer with quality and consistency that rivals those of a lab. This convenience helps doctors and patients reduce turnaround time for results. Units such as the fastprint.io™ 3D Printing Solution can help doctors save even more time and lab costs by producing crystal-clear appliances direct from the printer with minimal polishing required.

Send blog-related questions and suggestions to hello@glidewell.com.