3D Printing in the Dental Practice

3D printing is the next step for practices that embrace same-day in-office solutions. In my practice, we print orthodontic retainers, models and occlusal appliances. I especially love printing occlusal guards because the process is simple and it enables us to offer our patients a unique service that will continue to grow.

3D PRINTING STARTS WITH SOFTWARE

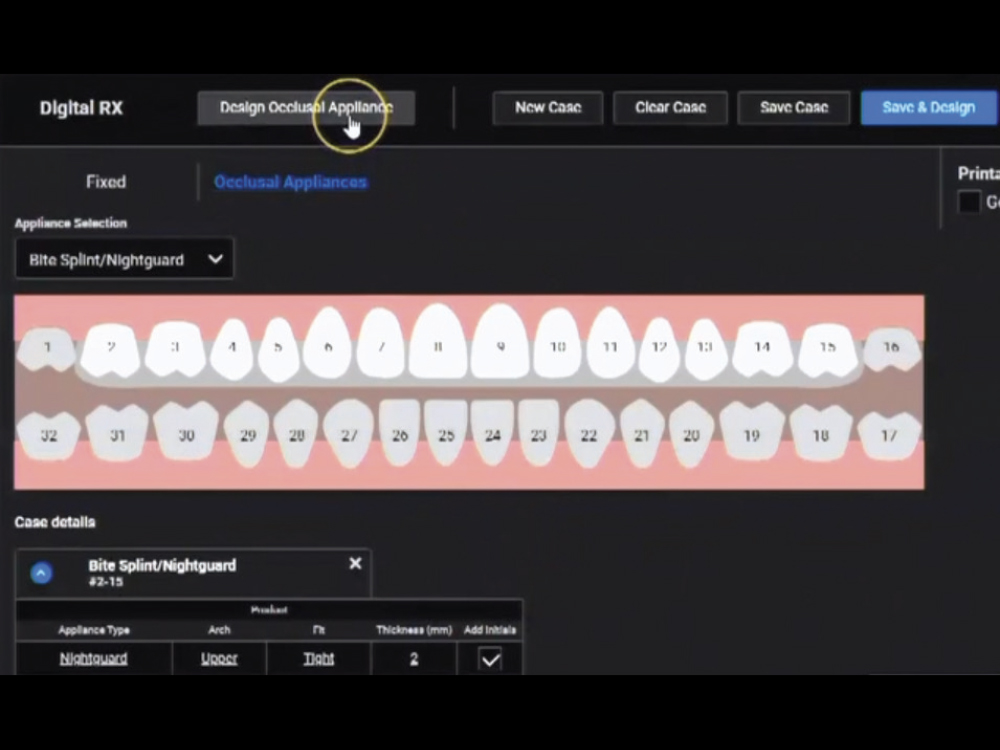

3D printing starts with the design software, which should be intuitive and easy to use. I find that the fastdesign.io™ software works well with my fastprint.io 3D printer to streamline the process. For example, when printing an occlusal guard, the steps are surprisingly uncomplicated.

Once I have imported the intraoral scan into fastdesign.io software, I simply select the Design Occlusal Appliance tab. Next, I select the arch — upper, lower or both — the desired fit and thickness, and press Design. In fact, there is no additional design work required to print an occlusal guard; just follow the steps.

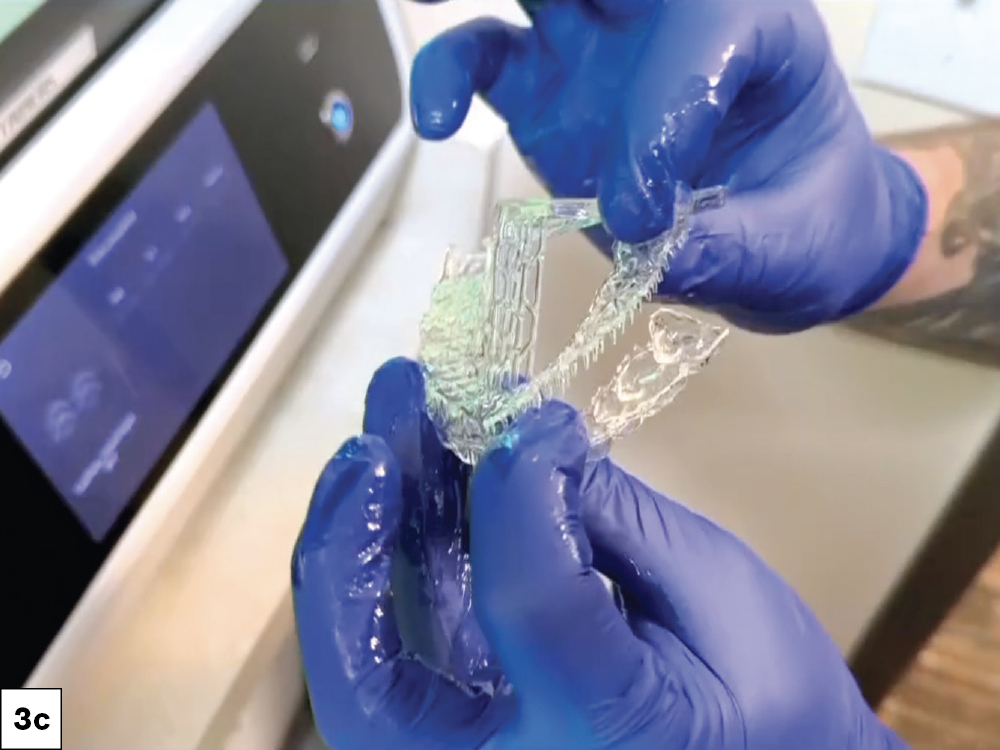

Once the occlusal guard is printed, there is no need for trimming or polishing. It comes from the printer exactly as designed in the fastdesign.io software. Just remove it from the print plate and supports, rinse and cure it, and the guard is ready to go.

THE PROCESS

Seeing the printing process is like watching a scene from a science-fiction movie. You are witnessing a tangible, three-dimensional object being crafted out of resin using only computer data and lights. It seems like magic.

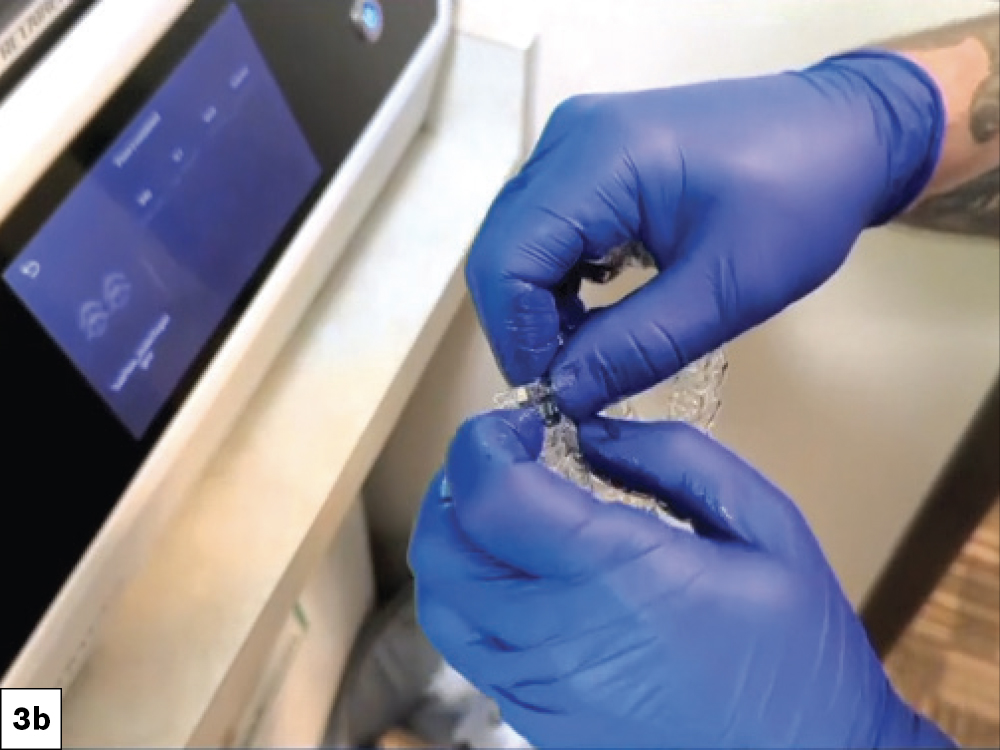

Once the object is crafted from the resin, post-processing requires popping the occlusal guard off the print plate and “unzipping” it from the support. The printed product goes into the wash unit for a rinse with isopropyl alcohol, which removes any uncured resin.

BENEFITS OF 3D PRINTING

A primary benefit for patients is convenience. If a patient is coming in for a hygiene appointment, for example, you can take a scan, send it to the fastdesign.io software, press print and have an occlusal guard ready during the same visit. A 3D-printed occlusal guard is also inexpensive to print. I estimate that it costs me $3–5 each for the consumable materials. I offer patients a free replacement if their occlusal guard is ever lost or damaged. As a benefit to the practice, 3D printing is another means of maximizing my glidewell.io™ system and promoting in-office dentistry.

As a benefit to the practice, 3D printing is another means of maximizing my glidewell.io™ system and promoting in-office dentistry.

THE FUTURE

My experience printing retainers and occlusal guards chairside has been so positive that I cannot help but envision eventually printing provisional and permanent crowns as 3D processes and materials progress.

However, the strength and esthetics of milling materials are unmatched by those of resins currently available for 3D printing. For example, provisionals milled with BioTemps® NOW are precise and durable, while resins used for 3D printing do not compare favorably. Milled restorations are so superior that – for now – I choose to mill rather than print my restorations. I plan to continue to evaluate new resins as they are introduced and add additional 3D-printed options as they become available.

For information on the fastprint.io™ 3D Printing Solution, please visit www.fastprint.io.