Digital Dentistry and the Dental Lab: Turning an Intraoral Scan Into an Ideal Restoration

The number of dentists adopting intraoral scanning continues to climb as clinicians take advantage of the high accuracy, faster turnaround time and reduced cost of restorations produced from digital impressions. But as anyone who has ever installed a new wireless router can attest, digital technologies are often not quite as straightforward as the instructions suggest. When doctors submit a digital impression, the integrity of the data is essential as the intraoral scan is converted into the virtual model upon which the restoration is designed. Any flaws in the scan data can hinder the dental CAD process and compromise the fit, form and occlusion of the restoration.

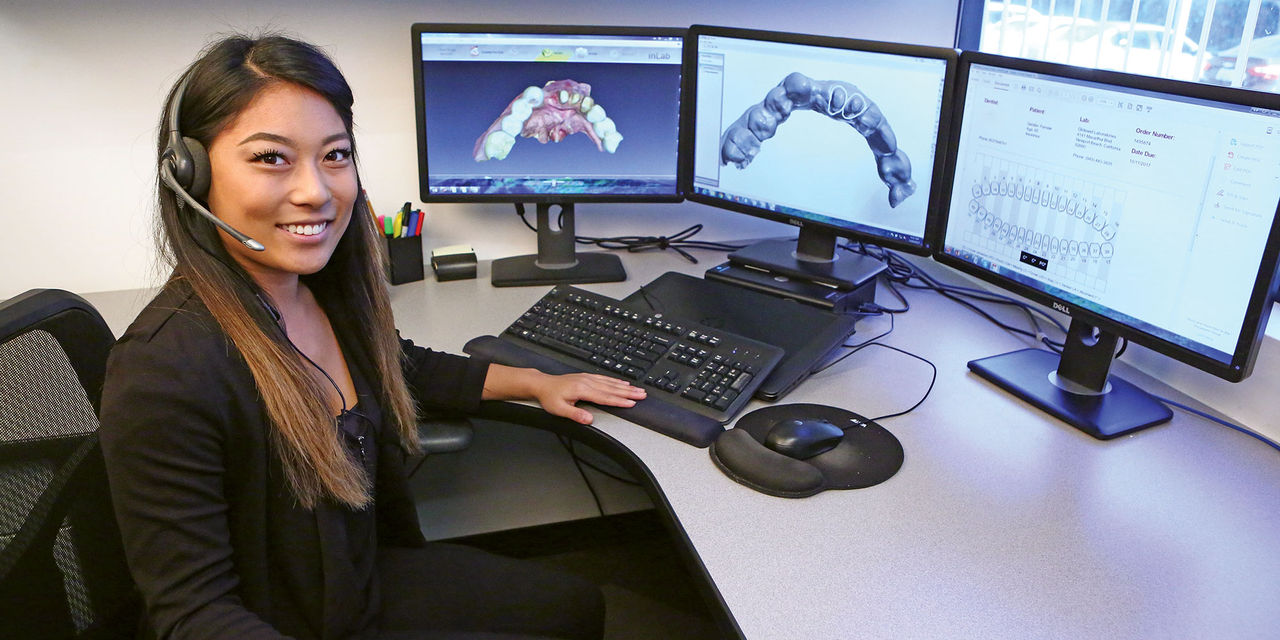

The Centralized Digital Order Processing (CDOP) department at Glidewell Laboratories was established with these exact concerns in mind, putting a specially trained team in place to evaluate, verify and prepare intraoral scanning data prior to restoration fabrication. By screening intraoral scans and correcting any deficiencies before the case enters the production workflow, CDOP ensures a highly accurate virtual model, allows the dental CAD technician to focus exclusively on the design of the restoration, and prevents problems with the margins, contacts and occlusion of the prosthesis.

THE ORIGINS OF CDOP

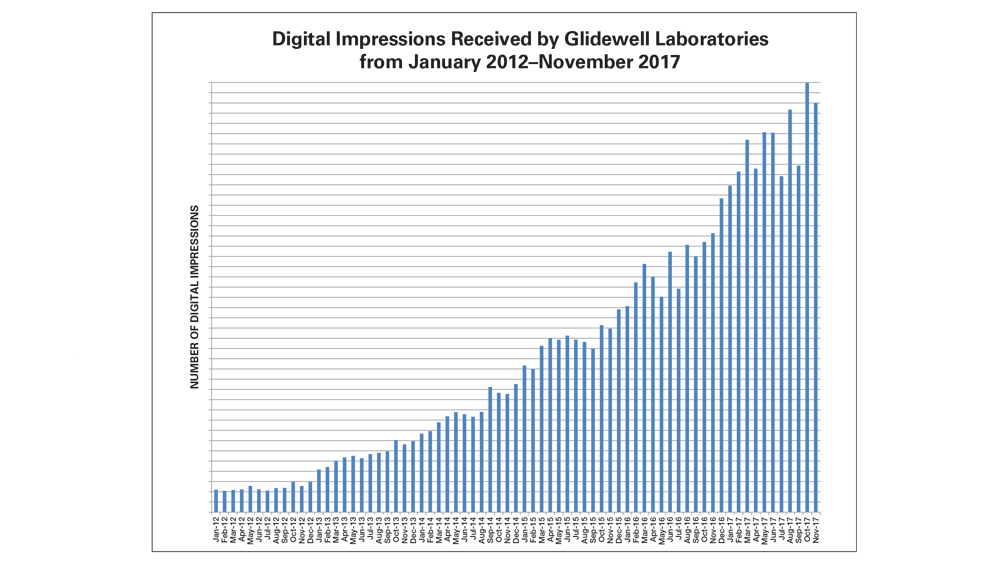

Prior to the creation of CDOP in June 2013, digital impressions were received directly by the individual Glidewell production departments responsible for fabricating the restoration. At that time, dentists were submitting a substantial number of intraoral scans per month, and data trends projected further growth amid the dental profession’s continual transition toward digital technology. The high level of quality control required to properly adapt to this surging demand necessitated the formation of CDOP, which has been tasked with receiving, screening and — when necessary — repairing the digital impressions received by Glidewell Laboratories. The importance of CDOP has increased in the years since, as the number of incoming intraoral scans has grown tenfold.

HOW CDOP ENSURES A HIGHLY ACCURATE RESTORATION

The Centralized Digital Order Processing team — the only one of its kind in the dental industry — is well-suited to handling the unique complexities of digital impressions. When dentists submit an intraoral scan to Glidewell Laboratories, it undergoes a rigorous screening and evaluation process to ensure the case is design-ready before production begins. Every CDOP technician is specially trained to process scans and understand the intricacies and workflows of a specific intraoral scanner. For example, experienced technicians are on hand to process and assist with digital impressions submitted via the following intraoral scanners. This ensures that all cases are subjected to the same high quality control standards, no matter which intraoral scanner has been chosen by the individual doctor:

- iTero® Element™ (Align Technology, Inc.; San Jose, Calif.)

- CEREC® Omnicam (Sirona Dental Systems, Inc.; Charlotte, N.C.)

- TRIOS® (3Shape North America; Warren, N.J.)

- Planmeca PlanScan® (PLANMECA CAD/CAM SOLUTIONS E4D Technologies; Richardson, Texas)

- Carestream® CS 3500 (Carestream Dental; Atlanta, Ga.)

- 3M™ True Definition Scanner (3M™ ESPE™; St. Paul, Minn.)

Note that while these are the dominant scanners currently on the dental market, Glidewell Laboratories has the ability to process digital impressions from any intraoral scanner that can output data in the standardized STL file format.

The number of doctors adopting intraoral scanning has increased steadily over the last five years, and CDOP has been essential in ensuring that incoming digital impressions meet the requirements for a well-fitting, functional and esthetic restoration.

Due to its experience processing an extremely high volume of digitally submitted cases, CDOP offers unparalleled expertise in identifying, troubleshooting and resolving the most common issues and errors with intraoral scans. Every time a dentist sends a digital impression to Glidewell Laboratories, CDOP performs the following screening and verification process, producing a flawless virtual model upon which to design the prescribed restoration.

- The digital impression is received by Glidewell Laboratories and routed to a CDOP technician who specializes in the intraoral scanner utilized to submit the case.

- The digital Rx is reviewed for completeness. The CDOP technician completes any missing information, contacting the prescribing doctor if necessary.

- The intraoral scanning data file is opened and the virtual model created from the digital impression is checked for the following characteristics:

- Correct inter-arch alignment

- Clear margins

- Sufficient restorative space and occlusal clearance

- A clear path of insertion for the restoration

- If any issues are identified in the above areas, the virtual model can usually be repaired using specialized software. In many cases, automated software is used to correct flaws or fill in gaps in the intraoral scanning data. In other instances, the CDOP technician works with the prescribing doctor in making changes to the virtual model, such as exposing the margin or making alterations to the preparation, adjacent teeth or opposing dentition. The CDOP technician provides the doctor with any information needed to make the corresponding chairside adjustments, such as screenshots of the changes made to the virtual model. When necessary, the CDOP technician contacts the doctor to request a new scan or a different material for the prescribed restoration.

The prescribing doctor performs the intraoral scan and submits the digital impression to Glidewell Laboratories.

After Glidewell Laboratories receives the digital impression, it is forwarded to a CDOP technician, who closely evaluates the intraoral scan for proper bite alignment, well-defined margins, sufficient restorative space, and a clear path of insertion.

- Virtual die-trimming is performed. This involves marking the margins so the dental CAD technician has a virtual removable die for restoration design.

- The CDOP technician then logs the case into order entry and imports the prepared files into dental CAD design software.

As a result of the CDOP screening and verification process, the dental CAD team receives a highly accurate virtual model for digital restoration fabrication, without the worry of flaws in the intraoral scanning data impeding the design process.

Because the intraoral scanning data is evaluated, prepared and optimized before the case enters the production workflow, the patient receives a well-fitting restoration with ideal margins, contacts and occlusion.

The screening process described above serves to optimize the scan data and ensures that the virtual model used in dental CAD design is highly accurate and free of any voids or deficiencies. Because this occurs before the production process begins, restoration fabrication proceeds smoothly and efficiently, resulting in a precise crown design with optimal fit, margins, contacts and occlusion.

CONCLUSION

With so many clinicians taking advantage of the precision, efficiency and long-term cost savings afforded by intraoral scanners, the ability of dental labs to quickly and accurately process digital impressions is essential in modern dentistry. The Centralized Digital Order Processing team at Glidewell Laboratories helps address this need by ensuring that intraoral scans are free of errors, promptly resolving any data deficiencies, and providing technical support for doctors encountering issues with their digital impressions. Because this screening process provides an ideal virtual model for dental CAD design purposes, the patient receives the most accurate, well-fitting and esthetic restoration possible.

THE CLINICIAN'S PERSPECTIVE

Interview with Dr. Chad Duplantis

by Chairside® magazine

As a general dentist who maintains a private practice in Forth Worth, Texas, Dr. Chad Duplantis is heavily involved with digital dentistry and has been working with intraoral scanning technology for over 14 years. Here, he shares his thoughts on the CDOP team and the benefits he’s experienced through partnering with Glidewell Laboratories for his digital restorations.

CHAIRSIDE® MAGAZINE: Can you describe your experience sending digital impressions to Glidewell Laboratories and working with Centralized Digital Order Processing? What benefits have you experienced through working with CDOP as your partner for digital impressions?

DR. CHAD DUPLANTIS: When I digitally submit a case to Glidewell, I get a notification the moment it’s received. We fortunately haven’t had many problems with the digital impressions we’ve sent in, but occasionally there will be a question about the margin or bite, and it’s very reassuring to receive feedback and communication from an able technician who can work with me in making sure the scan is perfect before the crown is designed.

CM: How does this differ from the experience you’ve had working with other labs?

CD: The biggest difference is the communication. I’m promptly contacted if there are any potential issues with my submission. Also, with Glidewell, everything has been fine-tuned to the point where I receive restorations in a very timely manner.

CM: Can you describe an experience you’ve had where CDOP identified and helped you correct a problem with a digital impression you submitted?

CD: I recently had a case where the patient had an open bite, so they worked with me in making sure that the bite scan was completely accurate. The restoration ended up being perfect despite the occlusal challenges of the case, so the extra care and attention paid off.

CM: How important do you think it is for a dental lab to have a department like CDOP?

CD: There are three key items to crown fabrication: margin marking, production, and polishing and finishing. Having specialists who are specifically trained to handle digital restorations and take care of that first element before the crown is designed is a huge plus. Knowing that there are quality control measures on the front and back end of the restorative process inspires confidence, and it shows with the fit, form and function of the restorations.

CM: For doctors who haven’t yet added intraoral scanning technology to their practices, do you see the CDOP team as a resource that can help smooth the path toward digital dentistry?

CD: So many things in dentistry are about checks and double checks. And when doctors are just getting started with digital impressions, having that second set of eyes looking over cases will be extremely beneficial. Dentists new to this technology will get more calls in the beginning, but receiving assistance from a specialist who can help you learn what to look for in a digital impression can help you get through the learning process faster and will ultimately benefit the quality of your restorations.