Publisher’s Letter: Making Implant Treatment Affordable for More Patients

Note: The Hahn Tapered Implant System is now known as the Glidewell HT Implant System

Dental implant treatment can be one of the most life-changing services we offer in dentistry, and like so many of the dentists we serve, we believe these benefits should be available to every patient in need. But the reality is that, for many practitioners, providing dental implant treatment is perceived as out of reach — a notion that was reinforced for many years by overpriced implant components, unpredictable prosthetic designs, and uncertain case profitability.

Starting nearly two decades ago, I sought to address these issues. By that time, our laboratory had already restored hundreds of thousands of implant cases, learning from the challenges and complexities that made implant treatment anything but straightforward. We used these insights to develop an implant manufacturing division — obtaining German-engineered machinery to fabricate our own prosthetic components in 2007, mini implants in 2011 and tapered implants in 2012.

However, implantology is about far more than precision-manufactured components. As our goal was to improve the availability of implant treatment, we recognized that every aspect of the process would need to be simplified — from initial training, to treatment planning, to surgery and ultimately to seating the final restoration.

We began seeking partners who had expertise in areas we lacked. We first connected with implant pioneer Dr. Jack Hahn, who has dedicated the last 50 years to making implant treatment more accessible to general dentists, including developing one of the most widely used implant systems in dentistry. Out of this partnership came the Hahn™ Tapered Implant System, which combines clinically proven features with contemporary innovation to meet the demands of modern implant dentistry.

From there, we joined forces with the Misch International Implant Institute, the group of educators that has continually advanced the standards for dental implant training for more than 30 years. Not only has our company hosted some of their comprehensive courses in our state-of-the-art classroom facilities, but we also rely on Misch faculty and graduates to keep our engineers and laboratory technicians informed of the latest developments in implantology, ensuring that our efforts are focused on solving real challenges.

Now, as implants have become the gold standard for the replacement of missing teeth, our company is firmly positioned to ensure the general dentist can participate. With our free and low-cost education opportunities, advanced surgical solutions, and full range of CAD/CAM custom laboratory services, we offer clinicians everything they need to deliver this superior form of treatment simply and reliably, case after case. And better still, because we do all of this in-house at our California facilities, we’re able to keep costs down as we’re not reliant on third-party manufacturers, distributors or middlemen — savings we’re excited to pass on to our customers.

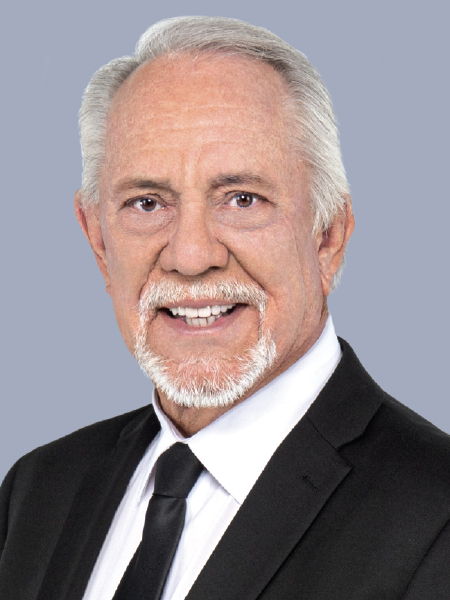

Yours in health,

Jim Glidewell, CDT

President and CEO, Glidewell