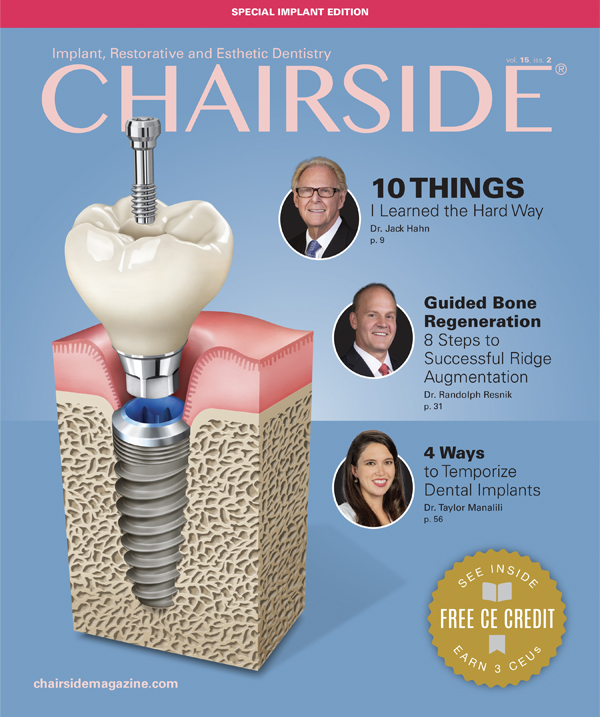

My First Immediate Load Full-Arch Implant Case

Note: The Hahn Tapered Implant System is now known as the Glidewell HT Implant System

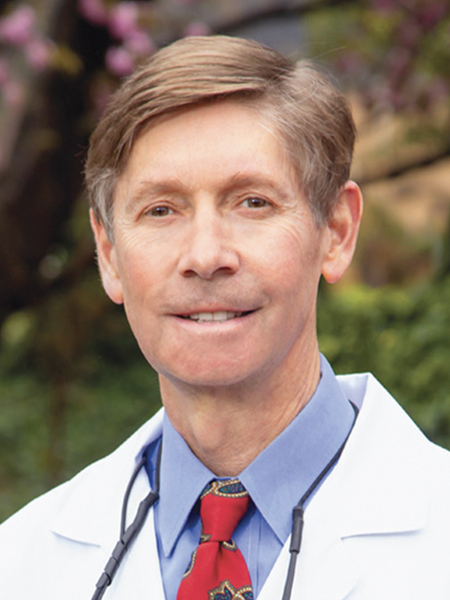

Dr. John Fish, a general dentist with a strong focus on implantology, takes pride in offering his patients a comprehensive range of implant treatment options at his practice in Hildebran, North Carolina. Here, he discusses how much implantology has changed since he began placing implants in the 1980s, the benefits of immediate loading in full-arch indications, and his recent experience providing his edentulous patients with the BruxZir® Implant Prosthesis, which has helped simplify his clinical workflow while avoiding the prosthetic wear and fractures common to other types of full-arch restorations.

CHAIRSIDE® MAGAZINE: Thanks for joining us today to discuss full-arch implant treatment and your recent experience with the BruxZir® Implant Prosthesis. To start, can you talk about how long you’ve been practicing dentistry and what led you to pursue this profession?

DR. JOHN FISH: I’ve been practicing dentistry for more than 30 years. My dad was an orthopedic surgeon and he loved his job, but I also saw that he had a lot of sleepless nights and he was on call a lot. I wanted to follow my father’s footsteps, but I thought that dentistry might be a better choice for me as far as work-life balance and autonomy were concerned, when compared with medicine. So midway through college I decided that I wanted to go to dental school, and I ended up at the University of North Carolina at Chapel Hill School of Dentistry.

CM: You’ve been placing implants since 1983. What inspired you to learn to place implants back then, when implants weren’t as mainstream as they are today?

JF: Coming out of dental school, I bought a practice that offered implants to its patients. I looked at several practices, but this one really jumped out at me because I was very excited about the possibilities that implant dentistry had to offer. The practice was owned by Dr. Paul Homoly, who has since become a renowned leader in dental implantology and had a significant nationwide following even back then. And he was selling this little practice in Hildebran, which is just west of Hickory, North Carolina. He was very generous with his time and taught me many very useful things, both clinical and managerial. I worked with him for eight or nine months, and this gave me a really accelerated introduction to dentistry and implant treatment.

Back in those days, root-form implants were not really the thing — it was more endosseous blades, ramus frames and subperiosteals. So I placed a lot of those early designs at a time when implant dentistry was quite controversial, really. Then the Brånemark implants came on the scene a few years after I started and, of course, now everything’s gravitated toward root-form implants.

CM: So did you receive most of your initial implant training from Dr. Homoly?

JF: I had zero experience or exposure to implants coming into dentistry because it was not taught in dental school. Implants were basically heresy back then, in 1982–83. So everything I learned early on was from Paul, who was placing implants every day. And of course, I embraced continuing education very early in my career. I got involved in the AAID and I became an Associate Fellow. I also joined the Dental Implant Associates of North Carolina, and we’d have live-surgery meetings. There were oral surgeons in the group as well as general dentists. There were probably 15 or 20 of us, and the group hung together for about 20 years. I got a lot out of that and formed a lot of strong mentor relationships with more experienced dentists.

Of course, these days, implant programs are more readily available. However, even back then I got involved with the Misch Implant Institute, though I had completed quite a few cases even before I went to see Dr. Carl Misch. I remember meeting Carl at the annual AAID meeting in Washington, D.C., in 1988. He said, “Come to my institute — I promise you’ll love it, and I promise you’ll get a lot out of it.” He was right. There was nobody quite like him — God rest his soul. He was amazing.

CM: How long have you been doing full-arch implant treatment, and what types of restorations have you worked with over the years?

JF: I probably did my first full-arch porcelain fused to metal implant restoration in 1984. I’ve done hundreds of implant overdentures, but doing fixed full-arch cases — to me that’s the pinnacle of dentistry. I’ve certainly done quite a few acrylic hybrid dentures, where you’ve got acrylic and denture teeth fused to a bar. When I used to do full-arch cases, any issues I experienced tended to be on the prosthetic end of things. It has gradually evolved, and with the advent of monolithic zirconia, we can provide this type of restoration with much more confidence, without worrying that the denture teeth will wear down or the porcelain or acrylic will break, chip off or delaminate.

As an experienced implantologist of over 30 years, Dr. John Fish has witnessed time and again how offering implant treatment in the general practice can benefit patients. He recently began prescribing the BruxZir Implant Prosthesis for his edentulous patients, and has seen dramatic improvement in the restorative workflow as well as the durability and esthetics of his full-arch restorations.

Dr. Fish recently placed five mandibular implants for a patient who requested a permanent solution for terminal dentition. He opted to place and immediately load five Hahn Tapered Implants with a fixed provisional denture. After the implant sites healed, Hahn Multi-Unit Abutments were connected to the implants and elevated the restorative platform above the soft tissue, thereby simplifying the fabrication of the immediate provisional denture as well as the final restoration.

My dental implant practice has culminated with full-arch zirconia implant restorations, and that’s been within the last three years or so. I’ve never seen a BruxZir Zirconia restoration chip, crack or fail in the seven years since I started working with the material. It’s a game changer. From single units up to full-arch implant restorations, BruxZir has to be the most successful dental material ever. It has revolutionized dentistry.

And doing a full-arch PFM on implants is way more labor-intensive — it’s just painfully slow going. There are just so many more layers and steps compared to the greatly streamlined workflow of doing a BruxZir Implant Prosthesis.

My next frontier is the immediate loading of full-arch cases, where you send the patient home on the day of surgery with a fixed, converted denture. Even back in the ’90s, Dr. Misch’s research showed that immediately loading a converted full-arch provisional denture was more predictable than doing one or two implants and loading them on the day of surgery, so the idea is not new. I’ve done a couple of those and picked up some great tips and tricks from my friend Dr. Paresh Patel at the full-arch implant course he teaches for Glidewell Clinical Education. He really helped build up my confidence that I should be doing immediate provisional implant dentures routinely. It’s a huge jump to go from placing the implants and waiting for them to heal to immediately loading a converted denture, so I’ve been grateful for the guidance and expertise provided by Dr. Patel. It makes such a positive impact on the lives of patients when they can leave your office with fixed teeth on the same day you place the implants.

CM: Can you talk about any notable cases you’ve recently restored with the BruxZir Implant Prosthesis?

JF: Sure. He had been a regular patient of mine for a number of years, and his lower teeth were failing at a pretty rapid rate due to periodontal disease. So we talked about all the options, and he finally decided it was time to move forward with replacing his terminal dentition. The patient had some esthetic and functional concerns, so a fixed implant restoration fabricated from BruxZir Zirconia was an ideal solution. He’s a huge guy — a bodybuilder, in fact — so the high strength and durability of monolithic zirconia was also important.

Prior to the surgical appointment, we had a temporary denture specifically made for conversion to a fixed appliance after placing implants. We took out his remaining lower teeth and immediately placed five Hahn™ Tapered Implants (Glidewell; Irvine, Calif.). I positioned the three anterior implants axially, and I angled the posterior implants mesially to avoid the inferior alveolar canal. I freehanded the surgical procedure, and it came out really well. We connected three straight multi-unit abutments to the anterior implants and two angled 17-degree multi-unit abutments to the posterior implants. Then, we prepared holes in the denture, did the pickup procedure with the temporary cylinders, reshaped it, and sent him home with the fixed, converted denture in place. This was my first immediate load fixed full-arch restoration on multi-unit abutments. As I mentioned earlier, this was a procedure I learned at Dr. Patel’s course at Glidewell. It was something I took home with me and was able to put it into practice within a few weeks. The patient is kind of a quiet guy, but it was obvious that he was really happy to leave there with fixed teeth.

After three months, we removed the converted denture, took impressions, and began restoring the case. We tried in the setup and everything looked good, so we sent it in to get it copy-milled. Glidewell sent us a provisional implant prosthesis to make sure everything was perfect. We seated the provisional and made sure he could clean it and liked the way it looked. We let him wear it for three weeks and there were no adjustments needed, so then it was a simple phone call to have the final prosthesis milled from BruxZir Zirconia. The final delivery appointment went very quickly because the patient and I both knew exactly what to expect thanks to the provisional. Like I said, the patient is not the most verbal guy, but when I handed him the mirror, he said, “I like it a lot,” and we could tell that he was very happy.

This workflow totally changed my outlook on full-arch implant treatment. This was just a huge leap for me, and when I see what can be done now with so much less effort and so much more benefit for the patient, it’s totally reenergized the way I practice dentistry.

CM: We’ve actually made multi-unit abutments a standard part of our restorative protocol for the BruxZir Implant Prosthesis, whether the dentist loads the implants on the day of surgery or waits until the implant sites have healed. How has your experience been with multi-unit abutments?

JF: They help tremendously in these cases because it elevates everything above the gingival tissue. When you get the multi-unit abutments in place at the beginning of treatment, it makes the try-ins, the provisional and the delivery of the final restoration an easier experience for the dentist and the patient. This particular patient was something of a dental phobic, and we only had to sedate him once. After placing the implants and connecting the multi-unit abutments, each subsequent visit went smoothly because we could easily attach the try-ins and didn’t have to worry about impinging on his gingiva. So just from the patient’s standpoint, he would tell you that he doesn’t remember one bit of pain or discomfort through the whole procedure. It’s phenomenal.

The denture converted to a fixed appliance (left) on the day of surgery was duplicated and sent to Glidewell to begin the restorative process. A provisional implant prosthesis (middle) was provided by the lab so the function, occlusion and esthetics could be confirmed by the doctor and patient. After a three-week “test drive,” the patient indicated that he was happy with the design and the final BruxZir Implant Prosthesis (right) was milled from monolithic zirconia.

CM: How often are you prescribing the BruxZir Implant Prosthesis for your full-arch cases?

JF: If I’m going to do a fixed full-arch, that’s my go-to restoration — period. It has all the advantages in terms of workflow, patient satisfaction, durability and quality. And they’re just utterly gorgeous. When I put the prosthesis in patients’ hands, they’re always amazed at the beauty. I don’t imagine I’ll ever deliver a PFM or acrylic hybrid denture for these types of cases again.

CM: Do you find a lot of value in the provisional implant prosthesis?

JF: It’s huge. It gives the patient a chance to test-drive the restoration, and it’s an exact replica of what we’re proposing for the final restoration. I wouldn’t think of going straight from the approved setup to the final restoration. It’s a very valuable intermediate step and basically allows the patient not only to preview the looks, but also an opportunity to function with it during real life. I wouldn’t do a case without it, and I’m glad it’s part of the service Glidewell provides.

CM: You mentioned that you did the restoration over Hahn implants — have you found that those work well in full-arch indications? When did you start using Hahn?

The final BruxZir Implant Prosthesis was delivered, completing a streamlined, predictable clinical workflow. The patient was extremely happy with the look and feel of the monolithic zirconia restoration, which affords the high strength needed to avoid prosthetic complications and does a great job of addressing the long-term needs of the patient.

JF: They work well in any indication. I’ve had great success doing everything from single units, to 3-unit bridges, to full arches. It’s a very versatile implant I can use anywhere, in just about any application. And the Hahn system offers a cost-effective approach due to the relatively low cost of the implants, the improved workflow and the 20% lab discount I receive for implant restorations through Glidewell. I can offer implant treatment with confidence at a significantly lower price point than I could before, which makes it easier for patients to accept treatment.

I started using the Hahn implant in 2015. I was attending a dental meeting in Las Vegas. Dr. Carl Misch, who was the creator of the BioHorizons implant I was using at that time, was there promoting the Hahn system as a more cost-effective alternative. I switched over pretty quickly after hearing Carl talk about the Hahn system, and my practice really transformed when I began using the Hahn implant and started working a lot with Glidewell.

CM: What general advice can you offer to any dentists out there who are considering switching to or learning how to provide monolithic zirconia full-arch implant restorations?

JF: First of all, I’d suggest leaning heavily on Glidewell, which pioneered this type of restoration and has a well-established reputation. They’ve been refining the restorative workflow for full-arch cases for years, and they have a great technical support team in place that can provide you with any help you need in restoring these cases. I’d also suggest taking advantage of Glidewell as a tremendous educational resource and attending one of their courses on full-arch implant treatment. Dr. Patel’s course was great, and it really opened my eyes to a lot of possibilities.