R&D Corner: Chipping Resistance — Traditional PFMs vs. Obsidian® Fused to Metal

Despite the surging popularity of monolithic dental restorations in recent years, the traditional PFM remains the restorative option of choice for many clinicians. Even dentists who prefer the strength and esthetics of all-ceramic materials will encounter clinical situations in which using a metal framework may be a better choice. While the demand for PFMs persists, there is also a desire for a metal-ceramic restoration that is more resistant to chipping. Indeed, clinical studies show veneer chipping and fractures as the major causes of failure for PFM restorations.1,2

While the demand for PFMs persists, there is also a desire for a metal-ceramic restoration that is more resistant to chipping.

This need to improve the PFM led to the creation of Obsidian® Fused to Metal (Glidewell Laboratories; Newport Beach, Calif.), which is produced by fusing lithium silicate ceramic to a laser-sintered metal coping. Nearly a decade of R&D efforts was necessary to develop a glass ceramic formulation that offered strength, vitality and the matching thermal expansion properties required to allow the material to be heat-pressed to metal. The result, Obsidian lithium silicate, replaces the porcelain of traditional PFMs with a monolithic layer better able to withstand functional forces.

Side-by-side examples of 3-unit bridges illustrate how Obsidian Fused to Metal (left) offers esthetics that compare favorably to traditional PFM restorations (right).

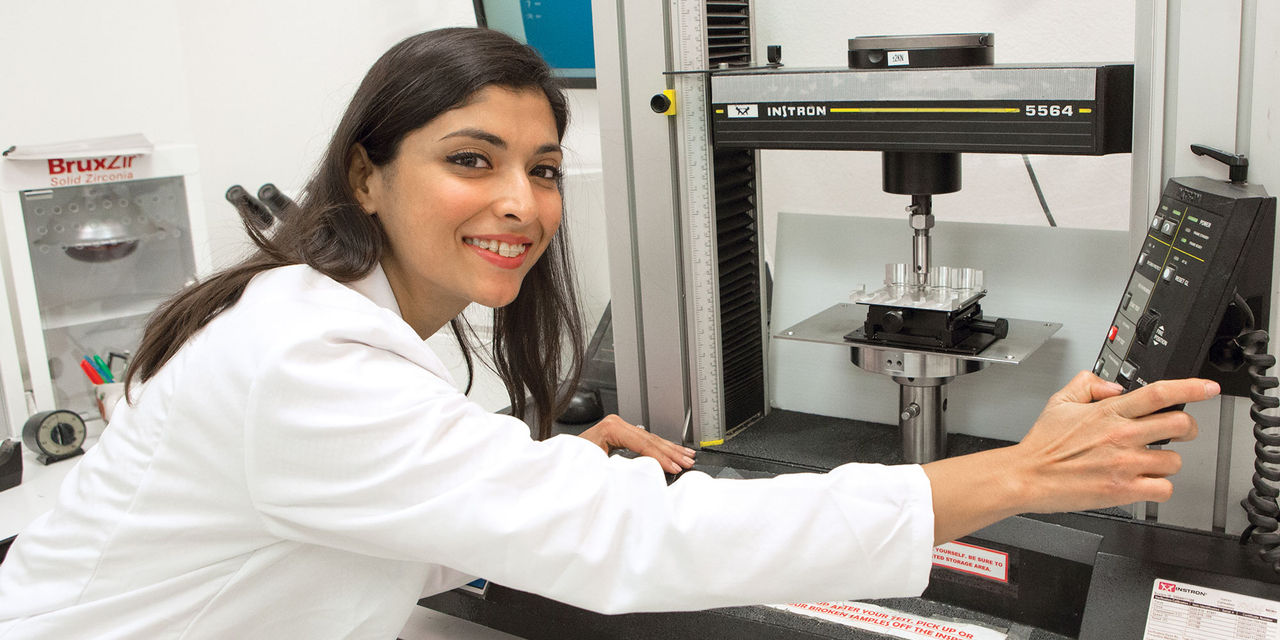

An in vitro study was recently conducted to compare the mechanical properties of Obsidian Fused to Metal with those of traditional PFMs produced with feldspathic porcelain. The biaxial flexural strength and edge strength of the two metal-ceramic restorative systems were tested to determine their relative resistance to chipping and fractures.

STUDY METHODOLOGY

The study compared bilayer metal-ceramic specimens representing the Obsidian Fused to Metal and Ceramco®3 PFM (Dentsply Sirona, Inc.; York, Pa.) restorative systems. Two types of tests were performed to determine the biaxial flexural strength and edge strength (i.e., chipping resistance) of each system according to the material preparation guidelines and testing methods outlined here.

Biaxial Strength Test

This test, conducted to determine the biaxial flexural strength of each restorative system, was performed on 1.5-mm–thick ceramic specimens pressed (Obsidian) or powder-stacked (Ceramco3) onto Argeloy® NP Supreme alloy discs (Argen Corporation; San Diego, Calif.). The alloy discs were 14 mm in diameter and 0.5 mm thick, and were cast using a lost-wax process followed by finishing, sand-blasting, ultrasonic cleaning and oxidation.

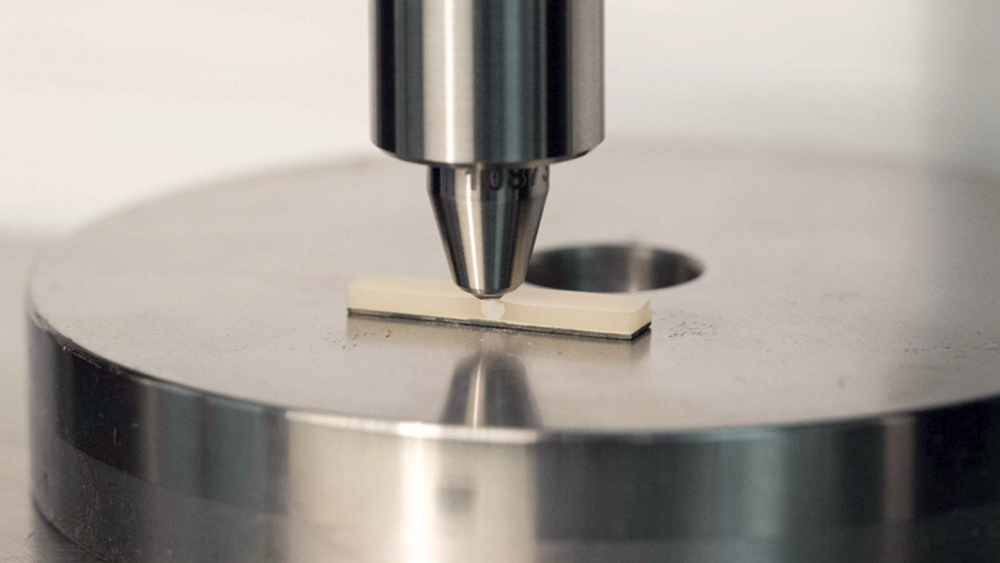

For the experimental setup used in the biaxial strength test, tension was applied to an Obsidian and a Ceramco3 bilayer disc until fracture occurred.

For the edge strength test, ceramic-metal bar specimens were loaded with a point force 1 mm from the edge of each sample until chipping was observed.

Each specimen was loaded under biaxial flexure using a piston-on-three-balls setup, an ISO-standardized test in which the bottom surface of the sample is supported by three balls and a piston is lowered at a set speed on the top surface, thereby mimicking multiaxial stress environments. Load was applied to the lithium silicate and porcelain test samples by vertically lowering the piston at a speed of 1 mm per minute. Tension was continuously exerted on the specimens until fracture occurred, and the load required for failure was recorded for each restorative system.

Chipping Test

The edge strength test, performed to determine how much load each restorative system could withstand before chipping occurred, was conducted using 1.5-mm–thick ceramic specimens pressed (Obsidian) or powder-stacked (Ceramco3) onto Argeloy NP Supreme alloy bars measuring 25 mm x 5 mm x 0.5 mm.

The two specimens were loaded with a Vickers indenter secured in a custom-made fixture attached to an Instron® Model 5564 testing machine (Instron; Norwood, Mass.). Load was applied with a cross-head speed of 0.5 mm per minute at 1 mm from the edge of each test sample. The load required to initiate edge chipping for the lithium silicate and porcelain specimens was recorded.

Obsidian Fused to Metal restoration of tooth #7. In addition to offering four times the flexural strength and more than twice the chipping resistance of traditional PFMs, Obsidian Fused to Metal exhibits lifelike color and translucency well-suited to the esthetic zone.

– Clinical dentistry by Anamaria Muresan, DMD, ME, CDT

RESULTS

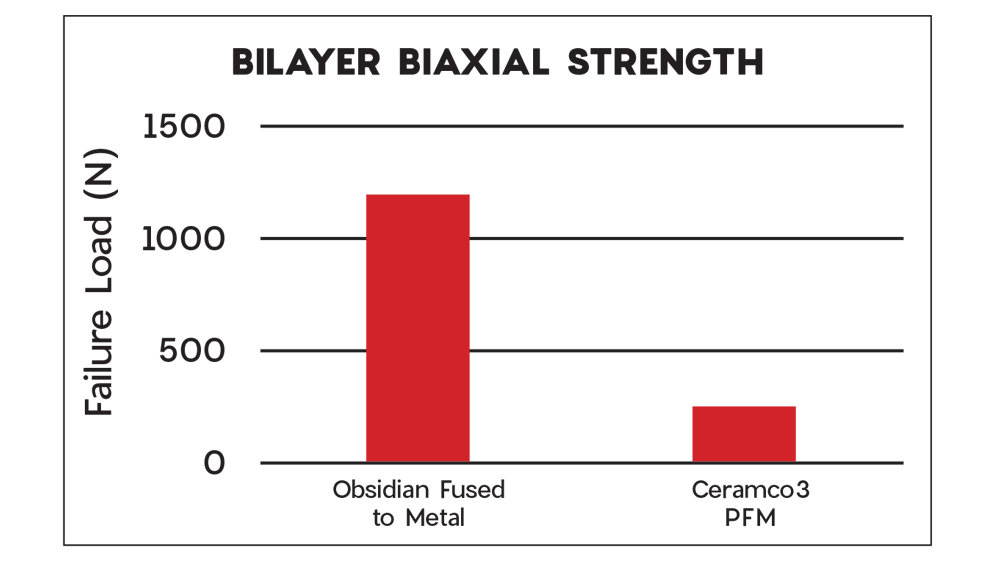

Biaxial Strength Test

The Obsidian Fused to Metal test specimen exhibited significantly higher biaxial flexural strength than that of the Ceramco3 PFM sample, including a load four times greater at the time of fracture of the metal-ceramic interface.

Graph depicting results of biaxial strength comparison shows that the Obsidian Fused to Metal sample withstood four times more load than the Ceramco3 PFM test specimen before failure was recorded.

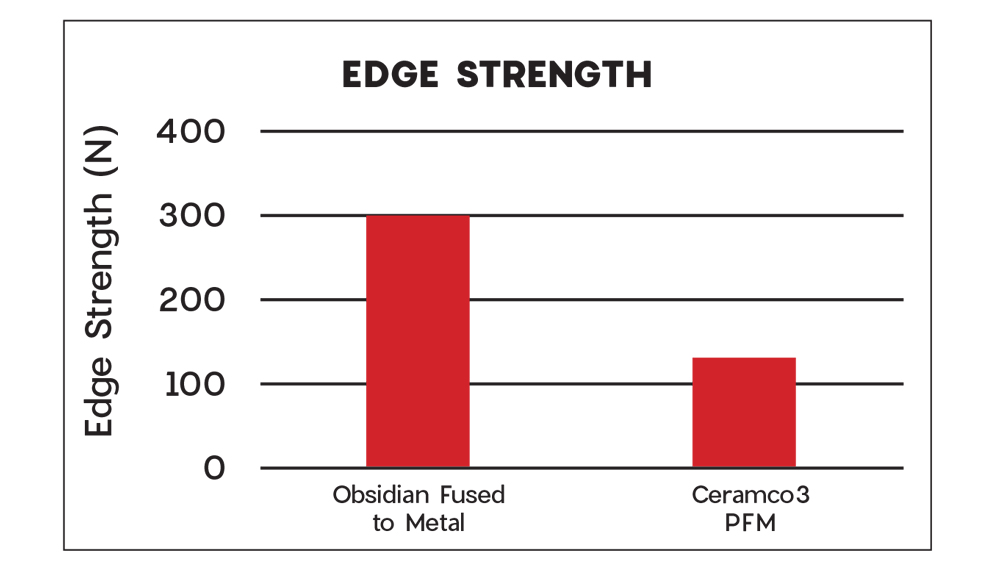

Graph showing the edge strength test results illustrates that a significantly higher load was required to initiate chipping to the Obsidian Fused to Metal specimen compared to the Ceramco3 PFM sample

Chipping Test

The results of the edge strength test showed that the Obsidian Fused to Metal specimen could withstand more than twice as much load as the Ceramco3 PFM sample before chipping occurred.

In this clinical case example, the patient’s posterior PFM crowns exhibited significant chipping and fractures after three years of use. In need of a more durable solution, the teeth were restored as a 3-unit Obsidian Fused to Metal bridge, improving upon both the strength and the esthetics of the original restorations.

– Clinical dentistry by Anamaria Muresan, DMD, ME, CDT

CONCLUSION

The Obsidian Fused to Metal restorative system showed superior mechanical behavior both in terms of fracture strength and chipping resistance compared to the porcelain-based metal-ceramic system. This could be attributed to the nano- and micron-sized crystals of lithium silicate glass-ceramic and lower porosity of pressed monolithic ceramic compared to powder porcelain. The results of this study suggest that Obsidian Fused to Metal offers a significantly higher degree of resistance to chipping and fractures than PFMs fabricated with feldspathic porcelain, providing clinicians with a more durable option for metal-ceramic restorations.

The Obsidian Fused to Metal restorative system showed superior mechanical behavior both in terms of fracture strength and chipping resistance compared to the porcelain-based metal-ceramic system.

References

- ^ Anusavice KJ. Standardizing failure, success, and survival decisions in clinical studies of ceramic and metal-ceramic fixed dental prostheses. Dent Mater. 2012 Jan;28(1):102-11.

- ^ Sailer I, Gottnerb J, Kanelb S, Hammerle CH. Randomized controlled clinical trial of zirconia-ceramic and metal-ceramic posterior fixed dental prostheses: a 3-year follow-up. Int J Prosthodont. 2009 Nov-Dec;22(6):553-60.