3D-Printed Immediate Dentures: A Case Report

Digital technology has enabled many advances throughout the denture workflow. From better-fitting record bases to functional try-ins without the need for wax, all aspects of denture design and fabrication can benefit from these new processes. And now, immediate dentures can be digitally designed from intraoral scans and 3D-printed at Glidewell, streamlining the clinical workflow.

Simply Natural™ 3D-Printed Dentures — Glidewell’s newly launched 3D-printed dentures — are an ideal solution when a temporary appliance is needed immediately after tooth extraction, prior to the completion of definitive treatment — whether that will be a complete denture or an implant-supported restoration. Whether the dentist makes a traditional impression or submits a digital impression to the lab, the case is digitized at Glidewell, allowing for a key benefit: The design of the prosthesis is stored in a virtual cloud so that if the patient damages or loses their denture, a replacement can be provided within a few days.

CASE REPORT

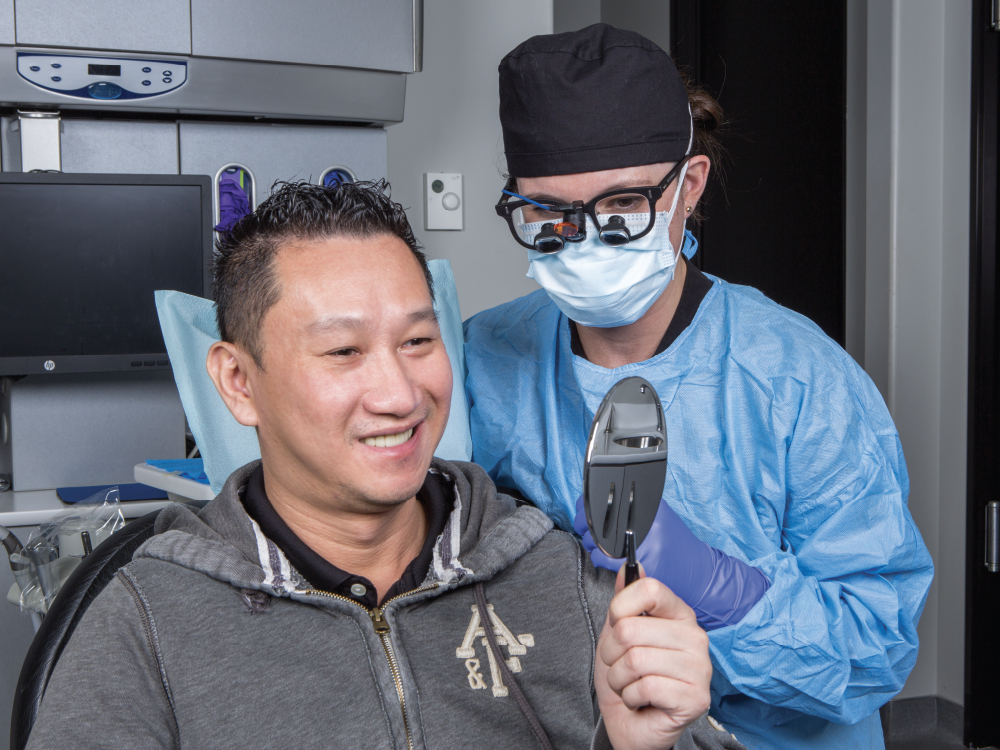

The patient presented with advanced periodontitis, dental caries and failing restorations. After CBCT analysis of the oral structures, a treatment plan was developed for extraction followed by grafting and healing, in preparation for eventual implant treatment. Because some of the patient’s teeth were extremely mobile, intraoral scanning was beneficial in simplifying the impression procedure for the fabrication of immediate dentures. The digital impression procedure also shortened turnaround time from the lab. After extracting the teeth, the immediate dentures were relined and delivered, serving as comfortable, esthetic appliances as the patient’s ridges healed in advance of implant treatment.

Figure 1: The patient presented with terminal dentition, requiring extraction and full-mouth rehabilitation. Implant treatment was desired by the patient, who will eventually receive fixed full-arch restorations.

Figure 2: CBCT imaging was obtained utilizing a VATECH Green CT 2 system (Vatech America, Fort Lee, N.J.), and these scans were used to evaluate the current status of the dentition along with the quantity and quality of the surrounding bone. My goal was to examine the patient’s bone levels and evaluate for any other issues that may have not been visible in my intraoral exam.

Figure 3: With many immediate denture cases, including this one, several teeth are mobile, so taking a traditional alginate or VPS impression creates a risk that the mobile teeth will be inadvertently extracted with the impression. For these cases, I utilize an iTero Element® 2 intraoral scanner. When scanning these cases, I disable the automatic cleanup feature, which allows me to capture more of the soft tissue. Alternatively, if an intraoral scanner is not available, conventional impressions can be sent to Glidewell, where they will be scanned and converted to a digital platform.

Figure 4: Once the scans were complete, I digitally submitted the files to Glidewell’s technicians for fabrication of the patient’s immediate dentures. Note that it’s important to review your scans to make sure you’ve captured as much of the vestibules as possible, as well as the entire palate, including the vibrating line, the maxillary tuberosities and the retromolar pads.

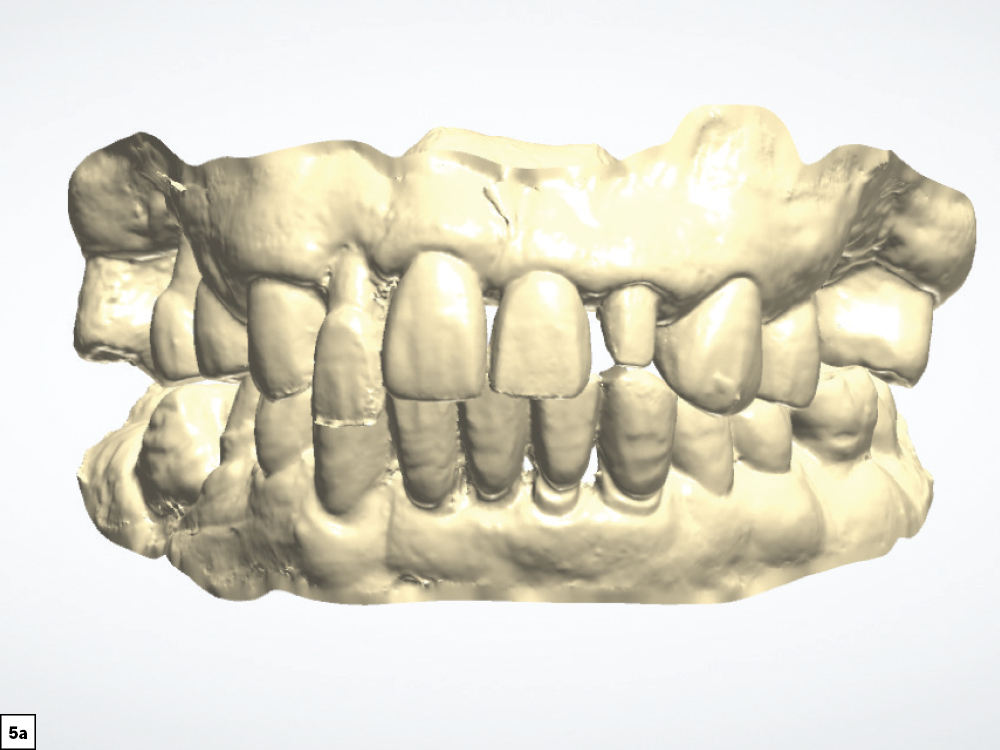

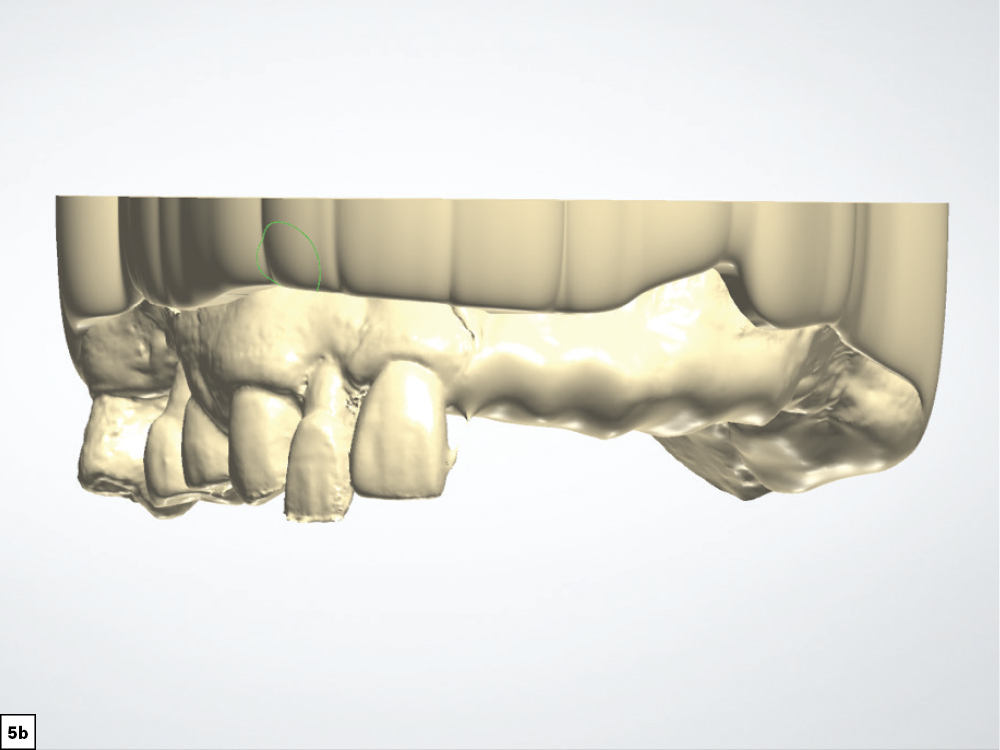

Figures 5a–5c: The lab converted the intraoral scans to virtual models for digital design of the patient’s immediate dentures. The technician digitally removed the patient’s teeth from the virtual models, and designed the dentures using advanced CAD software. The midline, incisal edge position, and tooth size and shape were created by referencing the patient’s existing dentition. Any desired alterations were communicated to the technician through the digital lab script. Clinical photos were provided as well for extraoral soft-tissue references.

Figures 6a, 6b: The Simply Natural 3D-Printed Dentures were 3D-printed by Glidewell based on the technician’s design and digital alteration of the patient’s pre-op scan. During the fabrication process, the denture base and teeth are 3D-printed separately and then bonded together.

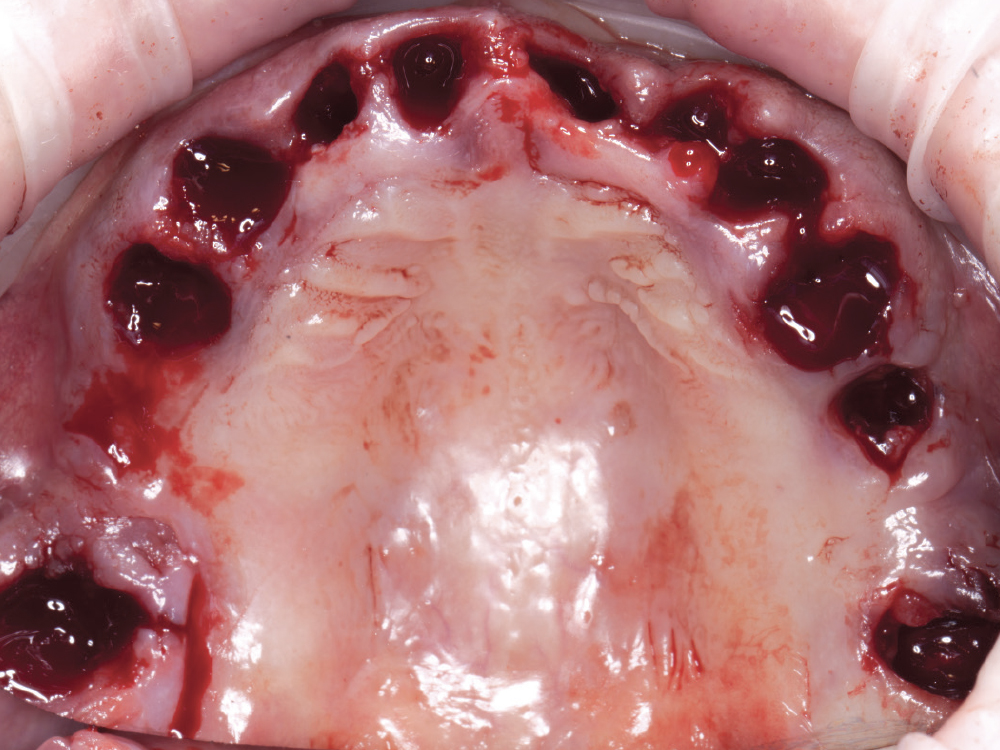

Figure 7: On the day of the surgery, I removed the patient’s remaining teeth, grafted the sockets, sutured, and placed his immediate dentures.

Figure 8: Ufi Gel SC soft reline material (VOCO America; Fort Mill, S.C.) was used to reline the immediate dentures. This type of silicone-based material provides the best retention to the 3D-printed base material. The dentures helped protect the healing ridges while also providing an esthetic improvement for the patient.

Figures 9a, 9b: These 3D-printed immediate dentures are utilized to give patients something to wear while they heal from the extractions, prior to the next phase of treatment. In this case, implants will eventually be placed to support immediate provisional prostheses, with a BruxZir® Implant Prosthesis serving as the definitive restoration.

CONCLUSION

Using advanced digital design and fabrication technology, the patient’s immediate dentures were created in a simple, efficient manner. The process involved taking the patient’s intraoral scans, sending the digital impression to Glidewell, receiving the dentures back, and then proceeding with the removal of the teeth and delivery of the immediate 3D-printed dentures. The steps were seamless and the patient loved leaving the office after surgery with a full complement of teeth that looked great and functioned better than he’d experienced in many years.

HOW TO PRESCRIBE SIMPLY NATURAL 3D-PRINTED DENTURES™

Digitally: Submit your full-arch intraoral scans to Glidewell via your scanner interface or upload through My Account. Indicate “Simply Natural Smart Dentures” in the case notes.

Traditional VPS Impressions: Download the removable appliance Rx at glidewell.com/removable-rx and select Simply Natural Smart Dentures when you send your prescription in with your full-arch impressions.