Poor to Excellent Function in One Day

Introduction

Minimally invasive devices and procedures are fast becoming the largest growth segment of the medical and dental device industry. When compared to traditional approaches, they require less anesthesia, shorten surgical and recovery times, reduce patient risk, and can offer significant cost savings. Over time, we have witnessed the research and development of smaller and smaller components. Mini dental implants dramatically improve the quality of the outcomes for patients seeking maxillary and mandibular overdenture treatment.

Small-diameter implants (1.8 mm to 3.0 mm) also differ from their full-sized counterparts in several ways. Their configuration allows for a more conservative placement protocol without involving tissue flaps or tapping procedures, resulting in minimal trauma for the bone and the gingival tissues. Mini dental implants’ size also allows the clinician to place them in ridges that might not otherwise be suitable for full-sized implants. Once these mini dental implants are firmly seated in place in intimate contact with bone, they can be immediately loaded with no lengthy waiting period or second-stage surgery.

The following case report will demonstrate the protocol for the placement of small-diameter implants, and the subsequent effects on the new prostheses.

Case Report

Diagnosis and Treatment Planning

A male in his late 70s presented to our office; he was frustrated with the look and fit of his upper and lower dentures (Fig. 1). Most importantly, he complained that his lower denture was nonretentive and nonfunctional, always falling out when speaking or while eating. He had been a denture wearer for the last 25 years, resulting in excessive resorption of the mandible. The patient also suffered from hypertension, which was controlled with medication.

The first phase of treatment would consist of having a new set of upper and lower dentures (Simply Natural Dentures™ [Glidewell Laboratories]) that would fit properly and occlude functionally. Utilizing recorded bases with corresponding wax rims, we analyzed the positioning of the teeth and proper proportions for an ideal smile. The patient desired to have his new set of teeth with shade B1 (VITA® Classical Shade Guide [Vident; Brea, Calif.]). When the patient viewed the wax try-in, he quickly approved them for processing (Fig. 2).

Outline of Clinical Treatment

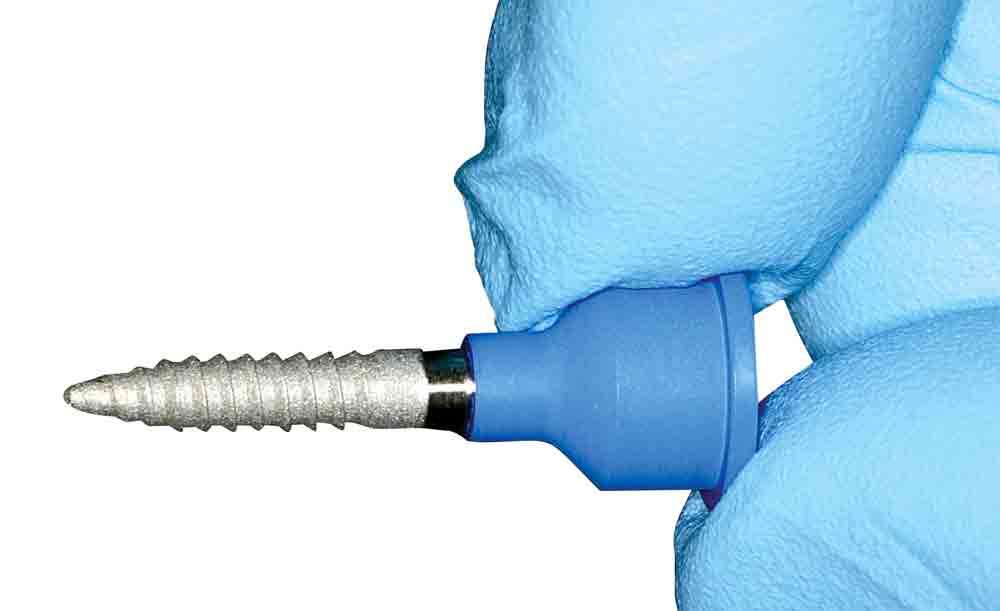

Palpation and radiographic examination revealed a moderately narrowed mandibular ridge (Fig. 3). Crestal bone and ridge height were sufficient to receive four 3 mm x 13 mm Inclusive® Mini Implants (Glidewell Direct) (Fig. 4). The thread pattern and pitch of this implant are purposely designed to immediately maximize bone-to-implant thread contact. Others like it include: I-Mini (OCO Biomedical; Albuquerque, N.M.), I6B (AB Dental USA; Los Angeles, Calif.), HM Implant (HIOSSEN; Fairless Hills, Pa.), MILO® (Intra-Lock; Boca Raton, Fla.), Midi® (Basic Dental Implants; Albuquerque, N.M.), Intermezzo (MegaGen USA; Englewood Cliffs, N.J.) and miniMARK™ (ACE Surgical; Brockton, Mass.).

After reviewing the patient’s panoramic radiograph, the mental foramina were also located, and it was confirmed that the four mini dental implants could be safely placed within the cuspid-to-cuspid area.

Before starting treatment, all the risks, benefits and alternatives were reviewed with the patient. A clean operating environment was established, the patient was draped and local anesthetic was administered. Then, an indelible marker was used to designate landmarks and areas of insertion.

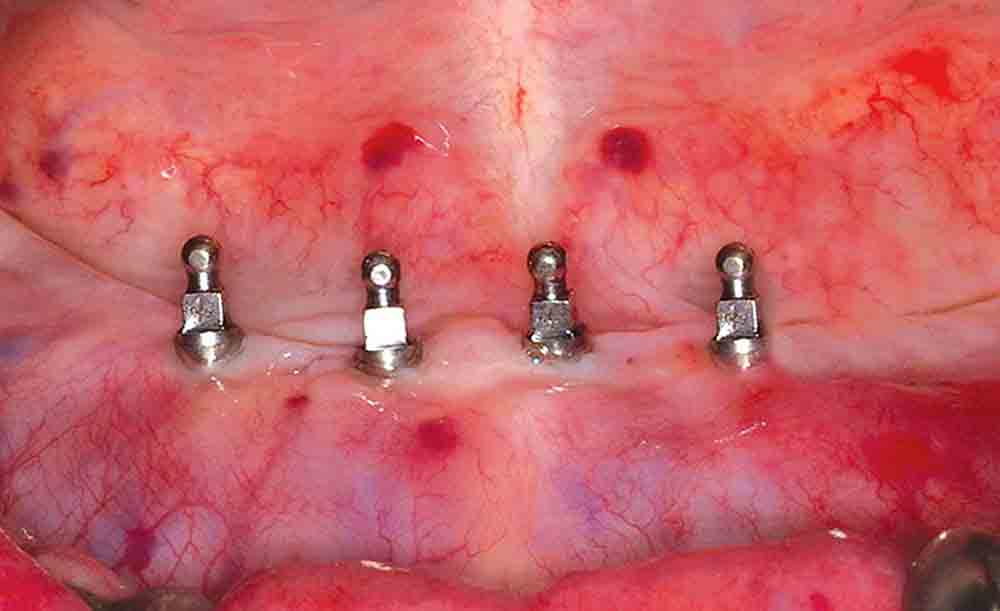

Keeping correct alignment, a 1.5 mm pilot drill from the Inclusive® Surgical Kit (Glidewell Direct) was placed into the sites and advanced to a depth of 15 mm, measuring from the tissue surface using a surgical motor (AEU-7000E [Aseptico; Woodinville, Wash.]) with generous amounts of sterile water. This additional 2 mm was the same depth of the tissue height to bone. In other words, 13 mm for the osteotomy in bone and 2 mm for tissue thickness was created to place a 13 mm long implant. Paralleling pins (Salvin Dental; Charlotte, N.C.) were placed in the sites of the osteotomies and an X-ray was taken to check the angulations to ensure proper orientation among the implant sites. Using a rotary tissue punch, a 3.0 mm outline was created over the initial osteotomies and the tissue plugs removed with a serrated curette (Zoll Dental; Niles, Ill.). The osteotomies were completed with the final drill (2.4 mm) included in the Inclusive Surgical Kit. Once the osteotomies were completed, four 3 mm x 13 mm Inclusive Mini Implants were placed in the osteotomies, using an implant finger driver (Fig. 5) until increased torque became necessary. The ratchet wrench was then connected to the adapter and the implants were torqued to final depth, reaching a torque level of 65 Ncm (Fig. 6). A postoperative radiograph was taken of the implants before initiating the prosthetic phase of treatment.

At that point, the location of each implant was transferred to the denture using bite registration material (Take 1® Advanced™ [Kerr Corp.; Orange, Calif.]). These areas were relieved to a diameter of 5.0 mm, and the denture was then reseated passively, confirming adequate relief had been properly established.

A covering silicone (Fit Test C&B [VOCO America; Briarcliff Manor, N.Y.]) was used to cover any undercuts or interface of the implants, allowing only the O-ball of the implant to be exposed. This step prevented problems of the pickup material locking around the implants. A female O-ring keeper cap (Inclusive) was then fitted over each implant. Retentive fit and mobility were again verified. Each O-ring would create a retentiveness of approximately 5 lbs. Because there were four implants with corresponding housings, the total amount of force needed to remove the prosthesis would be about 20 lbs.

The cleaned and dried recesses in the lower denture were filled with cold-cure acrylic (Quick Up [VOCO America]) (Fig. 7) and seated onto the implants, allowing it to polymerize. Upon setting, the lower denture was relieved of any excess flash, and the flange areas were relieved (Fig. 8). Finally, postoperative instructions were reviewed with the patient regarding denture placement, removal and oral hygiene. The patient was extremely excited and pleased that his new dentures were now very retentive and functional.

Implants Are Easy to Code: The Question Is the Final Appliance!

Tom M. Limoli, Jr.

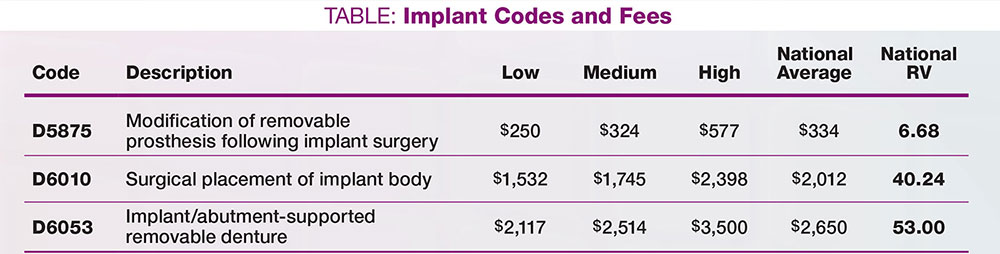

Gaining in rapid popularity are these so-called “mini implants.” They are sometimes referred to as “small” or “narrow diameter” depending on the precise dimensions as well as the specific manufacturer. From the coding, billing and reimbursement perspective, let’s separate the global procedure into its two major subcomponents. They are the implant and the existing denture that is now being modified to become an overdenture.

Procedure code D6010 identifies the surgical placement of the implant body. In reviewing thousands of claims for multiple implant placements during the same surgical series, it is not uncommon to find documentation and billing based upon the premise of the “single incision rule.” This type of billing generally results in the first implant being billed at 100% of the fee, while each additional at the same surgical visit being billed at some variation of 80%, 60%, all the way down to 40% of the fee for the first surgically placed implant.

When the technique involved is the modification of an existing removable denture to one becoming an implant-retained overdenture, they are globally identified with procedure code D5875. This code would only be applicable if we were simply going to be using the patient’s existing appliance with modifications. A weakness in the existing coding sequence is that code D5875 does not specify if the original removable appliance replaces either a partial or completely edentulous arch. Also the fact that this code, by ADA definition, does not require a “by report” clinical narrative makes the claim delay the inevitable. That is why I recommend that the code always be submitted with a description of the prosthetic modification along with the original date of placement and anticipated longevity.

As concerns Dr. Nazarian’s specific technique and treatment plan for this individual patient code, D5875 would not apply because the completed “global” procedure is in fact an implant-retained overdenture identified by code D6053.

Closing Comments

The advent of the mini dental implant has given general dentists an efficient and more affordable way of solving many of the challenges associated with complete dentures. In providing mini dental implants that immediately improve denture function and retention, the clinician can rapidly restore a patient’s confidence and also yield positive economic benefits for the practice. In addition, the simplified protocols, conservative procedures and elimination of gingival surgery make mini dental implants ideal for medically, anatomically and financially compromised patients.

It has been estimated that more than 36 million patients in the United States have lost their teeth; however, 0.5% have received implant therapy. This striking disparity signifies a huge untapped market for implants and dentures!

General References

Dr. Nazarian maintains a private practice in Troy, Michigan, with an emphasis on comprehensive and restorative care. He can be reached at 248-457-0500 or at premierdentalcenter.

Disclosure: Dr. Nazarian reports no disclosures.

Reprinted by permission of Dentistry Today, © 2012 Dentistry Today