Better Crowns with Artificial Intelligence: Reduced Chair Time and Fewer Remakes

When I joined Glidewell in 2012 to start our artificial intelligence program, we made two pivotal decisions. First, we started developing our own proprietary digital crown design software. Second, we became very early adopters of cloud computing by working closely with Amazon Web Services (AWS). These decisions allowed us to accumulate vast amounts of data across millions of cases that we now use to build AI software. Today, thanks to this early investment, we can produce digital crown designs almost instantly, which are then milled and ready to ship back to the dental practice faster than ever.

THE EVOLUTION OF AI CROWN DESIGN

If you ask any two technicians to design the same crown, the designs will invariably look different. How do we achieve consistent design at scale? One of the early approaches to AI crown design involved analyzing data derived from millions of crowns in the cloud to find a design that most closely resembled the design required. Rather than create the crown designs from scratch, the technician could simply adjust and tweak it as needed.

Then, AI technology evolved further, producing advanced capabilities like “deep fake” videos that imitated the look, sound and mannerisms of real people. AI became capable of creating something on its own, not just referencing a previous design. Restorative dentistry also utilizes imitative properties to mimic the look, feel and function of real teeth. That’s why we selected the best true-to-life designs from our most experienced technicians and created digital designs, which we sent to our proprietary CrownAI™ cloud service.

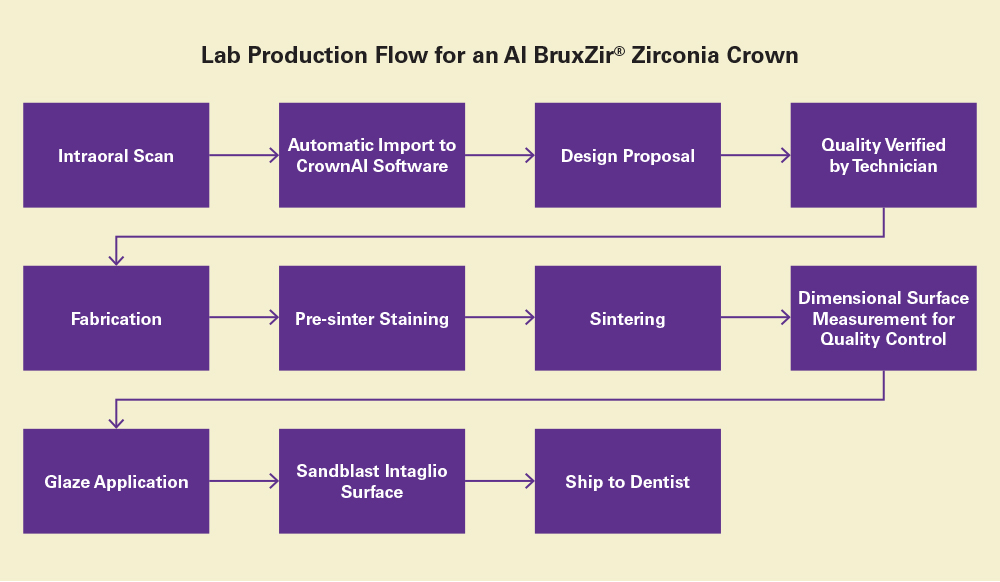

Now, we have a cloud library that can start with an intraoral scan, or a scan we make from a traditional impression the doctor sends, and generate a fully automated, realistic design using AI. The electronic file then goes to one of our technicians who reviews the design for overall quality. Once approved, they send it to our digital manufacturing factory for milling.

We selected the best true-to-life designs from our most experienced technicians and created digital designs, which we sent to our proprietary Crown AI™ cloud service.

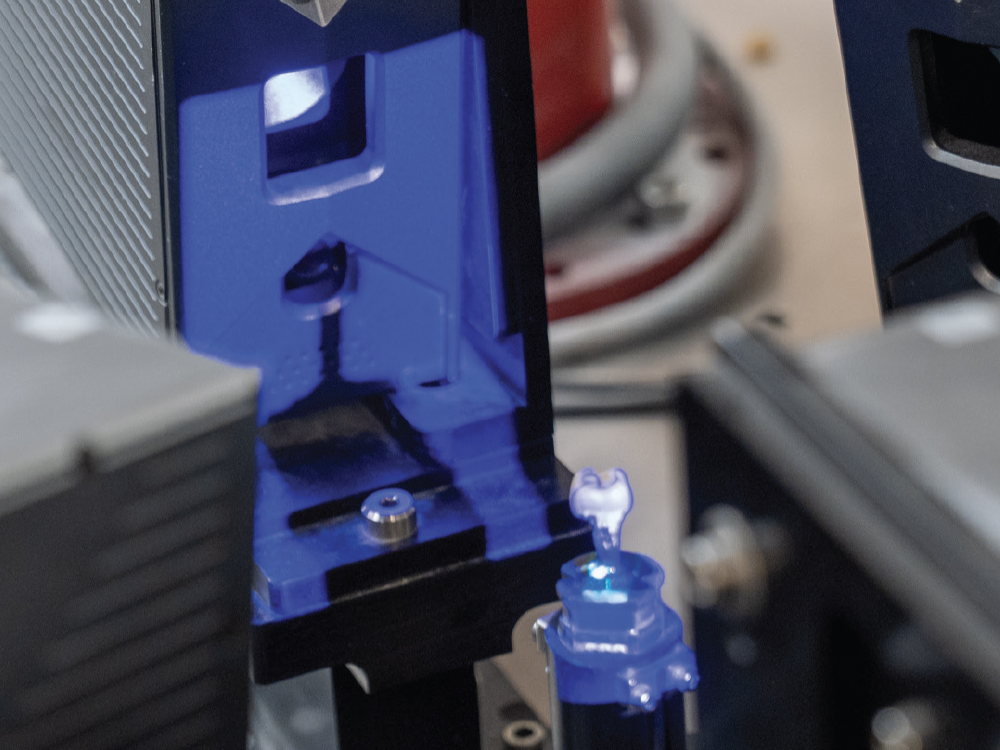

Reducing Production Time and Remakes with CAD/CAM Technology

While our AI software is fast and generates excellent crown proposals, it is not of much use until it is coupled with an efficient manufacturing system. We developed an automated facility called “BruxZir® Automation.” The facility contains several production lines that consist of twenty interconnected mills that are fed BruxZir Zirconia blocks by a series of robotic arms. Once milled, the crowns go through the rest of the production process, including pre-sinter coloring, sintering, glazing and sandblasting of the intaglio surface. The entire process is exceptionally quick. It is not unusual to get an intraoral scan from a doctor and have the finished crown milled and shipped the next day.

We have minimal human intervention during the production process, which provides exceptional consistency. Quality control is maintained using Dimensional Surface Measurement (DSM) cameras. These cameras measure the surface of the finished crown and make sure it precisely matches the specifications from the original design. If the camera detects a match, the crown is glazed and shipped to the doctor. If an issue is detected, the crown is automatically rejected and sent to be milled again. This process greatly reduces doctors requesting remakes and gets us closer to the ultimate goal: precision-fit crowns that are ready to seat on delivery day.

It is not unusual to get an intraoral scan from a doctor and have the finished crown milled and shipped the next day.

Saving Chair Time with Scanning and AI

Much like AI, intraoral scanning technology is advancing quickly. The cost of scanners has dropped, while at the same time speed and resolution have increased. Additionally, intraoral scanners are faster than traditional impressions and provide higher capture precision while eliminating impression distortions. Real-time feedback with the capture software allows dentists to check the scan for accuracy before submission to the lab. When the scan is imported into AI software that designs the crown, the result is a streamlined, integrated digital system that reduces errors and saves a lot of time both chairside and in the lab.

Today, we have fabricated millions of crowns generated by this AI technology. We’ve seen productivity in the lab go up nearly four times. In 2012, our average technician was designing about 50 crowns a day. Today, our best people design over 200 each day with the help of AI. We can scale without compromising quality.

We’ve applied AI to other indications as well, including bridges, screw-retained crowns, nightguards, dentures and esthetic cases. We’re getting to a point where essentially every single design of every single indication can be highly automated and result in cases that are indistinguishable from those designed by hand.

Designing and producing crowns boils down to high quality and speed. We’re now producing most crowns with a three-day turnaround. Or, for a slight added fee, we can even deliver your case in less than 24 hours. When Jim Glidewell founded his company in 1970, he began with a vision of providing high-quality, affordable dentistry to as many dentists and patients as possible. With AI, we continue to bring this vision closer to reality.