Adding a New Dimension to Your Practice with 3D Printing

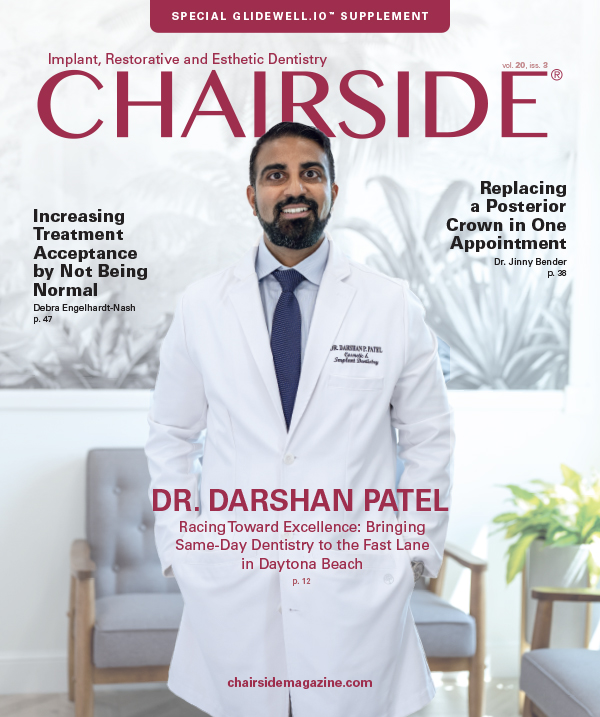

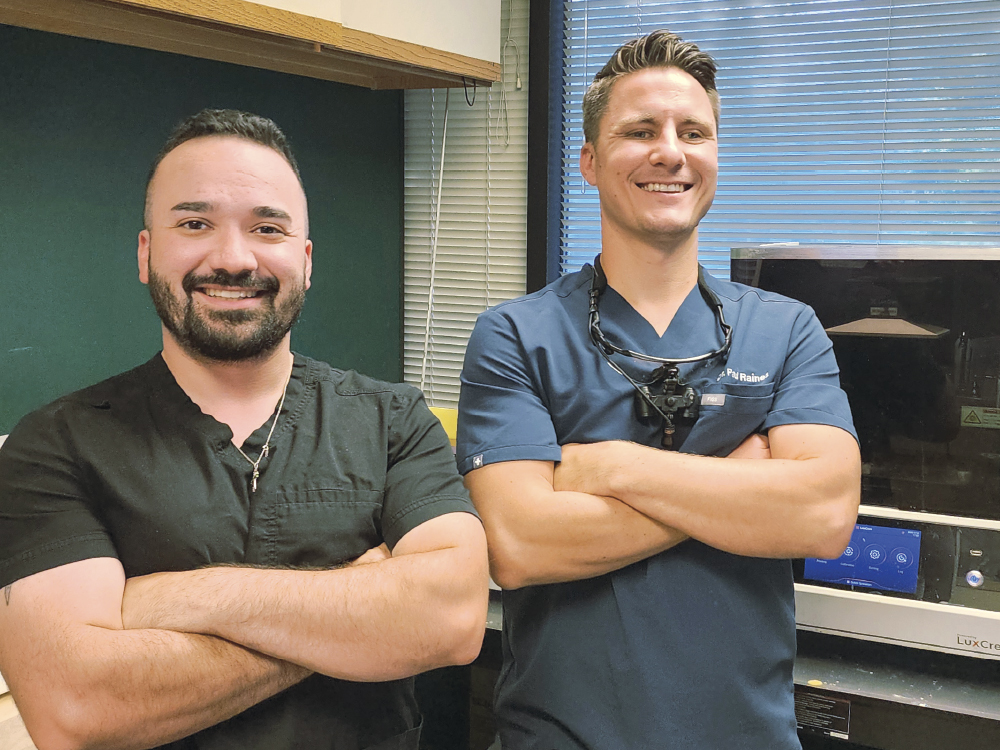

When Dr. Paul Raines brought the fastprint.io™ 3D Printing Solution into his practice in December 2023, it wasn’t just a tech upgrade — it was a commitment to greater precision, efficiency and patient-centered care. Seamlessly integrating with his existing glidewell.io™ In-Office Solution workflow, this new addition marked a major step forward in his digital journey.

CHAIRSIDE® MAGAZINE: How important is digital dentistry to your practice?

DR. PAUL RAINES: I think we are in a digital golden age. From the moment I decided we would be a digital office, the rewards have been great. We’ve been growing year after year because we have really harnessed these digital workflows and are giving patients what they want: convenience, efficiency and quality.

My digital journey began in 2020 when I got my first iTero Element® scanner (Align Technology, Inc.; San Jose, Calif.). I bought my first mill in 2022, and demand for same-visit treatment prompted us to get a second mill a few months later. By the end of 2023, we had incorporated a 3D printer.

CM: Did you conduct a financial analysis before purchasing your fastprint.io™ 3D Printing Solution?

PM: With every piece of technology, I always do a return on investment analysis to determine how much new revenue we can bring into the practice. For example, we do around one hundred cases of clear aligner therapy in a good year. If we can 3D print the final retainers ourselves, that saves me money. I can literally say that my printer is being paid for by the clear aligners savings, and everything after that is additional revenue.

My lab technician, Tyler, had a lot of training in how to 3D print single-unit and multi-unit implant surgical guides. With a 3D-printed surgical guide, the iTero scanner, and the fastmill.io™ In-Office Mill, we can quickly and precisely place a single-unit implant. Considering how affordable the glidewell.io In-Office Solution is, the workflow is hard to beat.

CM: What other uses have you found for your printer?

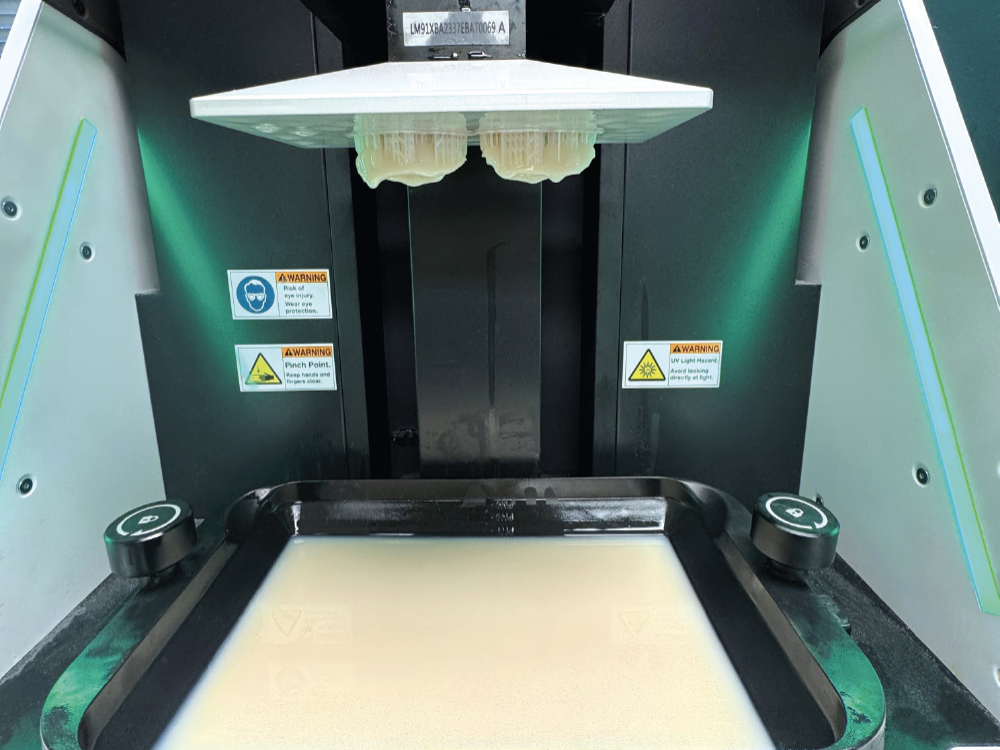

PR: Let’s take today as an example. The schedule involves a 3D printer in almost every one of our procedures: At 2 o’clock, we are going to extract teeth on a patient’s upper arch and seat a full denture that was 3D printed on the fastprint.io printer. We will also print a 3D diagnostic model for his lower arch to propose a new procedure. Then, we have a surgery case where we will extract a tooth and immediately place an implant using a surgical guide that we printed. Toward the end of the day, we are printing three sets of retainers for a clear aligner therapy case that just finished.

TYLER ROSE: We use the 3D printer for everything. As a matter of fact, today I have already finished printing a presurgical edentulous model, a digital tooth reduction guide, and a denture. I would say that our printer usage is broken down into 30% retainer-related, 40% implant-related, and 30% prosthesis-related solutions.

CM: How has a digital workflow impacted your practice?

PR: Our current digital in-office setup has helped us streamline our practice, made us more efficient, and turned 90% of our work into same-visit treatments.

When I bought the fastmill.io In-Office Mill, I thought I had bought a complete digital solution for the office, but I was wrong. The 3D printer is a part of the digital solution ecosystem. The fastdesign.io™ Software and Design Station works seamlessly with the rest of the digital workflow and allows me to do all kinds of 3D cases, including wax-ups for full-arch cases. If I can’t 3D print it and need something a little bit stronger, I always have the option to send it to the lab. Having access to fastdesign.io software gives us the opportunity to take advantage of our digital workflows.

Another great advantage is being able to show a patient what you are going to do, and what the result will look like. Using the software, I can present them with a clear picture of what the end result will be. Sometimes, I will even 3D print the proposed solution for them. Nothing beats being able to showcase the 3D-printed physical model of the work you will do for them.

CM: What aspect of the fastprint.io 3D Printing Solution impressed you the most?

PR: The Glidewell 3D printer is so accurate that the surgical guides fit intimately. The surgical placement from these guides is immaculate. We recently had a patient who walked in and needed two teeth extracted. We took a CT scan and told him that we could plan an implant and fabricate his surgical guide in about an hour, so he waited while we printed the guide that we used to extract his teeth and immediately placed the implant.

CM: What patient-centered improvements have you seen since adopting this technology?

PR: A patient can come in with a missing tooth or a tooth that needs to be extracted and walk out an hour later with an implant that was completely guided and precisely placed with a printed surgical guide.

Nothing beats being able to showcase the 3D-printed physical model of the work you will do for them.

CM: Has the printer contributed to additional production in your practice?

TR: We experienced a significant increase in our crown & bridge production. What made the difference is the ability to show patients a real, tangible model of the outcome. It’s helped us present more comprehensive treatment plans — and patients are saying “Yes.” The final restorations match the models they approved, and we deliver everything in less time.

Since adopting 3D printing and guided surgery two years ago, our implant production has grown from five implant cases per year to 65 implant cases in just the first five months of this year. But it’s so much more than just an implant service. The software is great for treatment planning and final solutions. Whether the 3D-printed product is being used as a model, a temporary solution, a guide to treatment, or a final appliance, digital dentistry made it all possible.