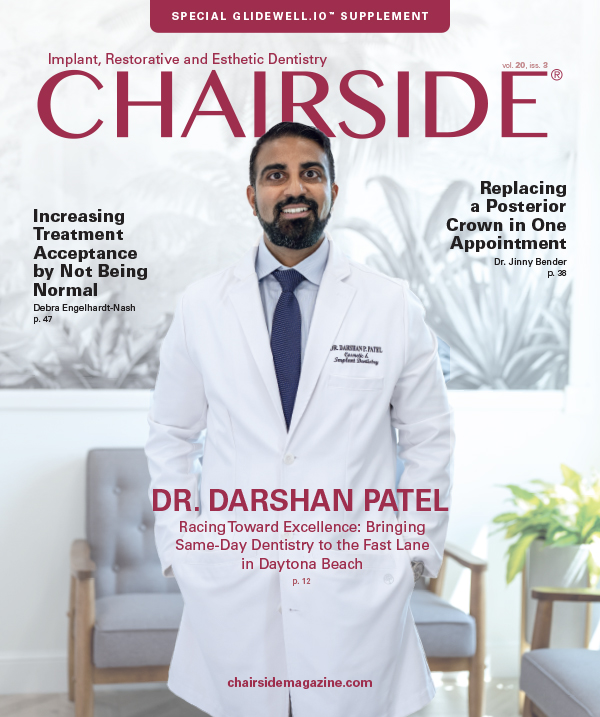

Third Mill’s a Charm: Optimizing Chairside Productivity

After my exposure in dental school to early CAD/CAM systems that were difficult and time consuming, I was hesitant to use CAD/CAM milling in my office. That changed when I came across the glidewell.io™ In-Office Solution. At the time, I was building a 14-operatory practice and was looking for the right digital partner to ensure my success.

The fact that the glidewell.io system uses AI to design crowns immediately caught my attention. Even more compelling was the idea that this could be a staff-driven technology and would not require my constant involvement or expertise.

MILLING 1-2-3: MY FINANCIAL APPROACH

I have a 14-operatory practice and wanted to make sure I had enough mills so that I could always say yes to treatment. When I made the investment, it was just me and one associate. So, when I decided to invest in my first mill, I ran the numbers.

I looked at how many crowns I was doing each month and calculated the associated lab fees, as well as the time and cost of making temporaries and setting up a second appointment just to deliver the final crown. I considered the monthly mill payments, the number of crowns I expected to mill per machine, and the cost of each block to reach a reliable per-unit cost. But for me, the real dealmaker was being able to offer same-day crowns to my patients, which I knew would set me apart from other practices in my area.

I believe the only thing that should limit our production is the flow of patients. For this reason, I made the bold decision to purchase three mills at once because I didn’t want to be limited by my equipment. And knowing I could count on outstanding training and support from the people at Glidewell gave me the confidence to go forward.

ALL-STAR TRAINING

My team has adopted technology with open arms. They have received in-office training, and I’ve sent team members on multiple trips to the Glidewell campus in Irvine, California, for additional training. We also continue to receive live, online support during our design process and have access to designated representatives who can answer any questions we may have.

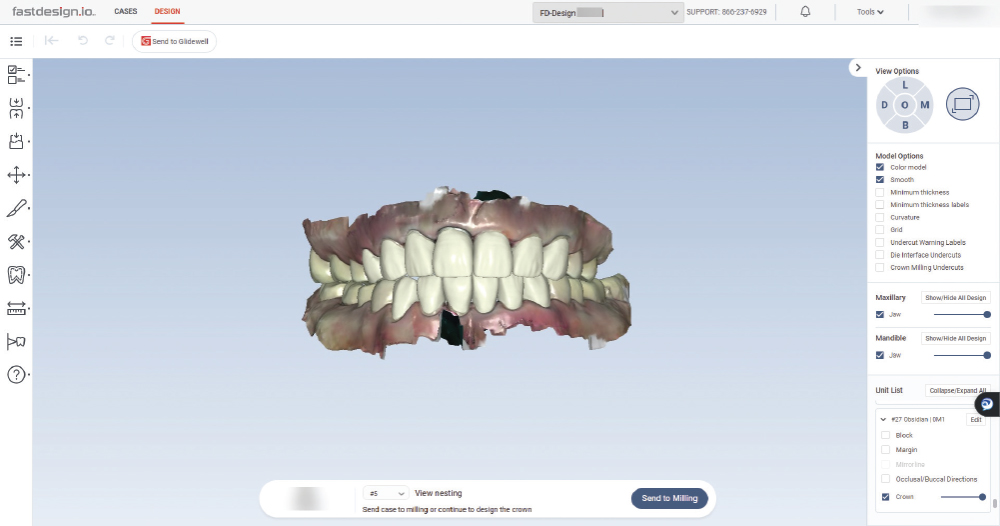

My team is truly adept at using this technology. While I’m treating patients, my team will scan, design, mill, and seat the crowns, and they’ll take an X-ray to confirm fit — all before they get me to give final approval and deliver the final crown.

TECHNOLOGY ENHANCES PATIENT CONVENIENCE

What patient wouldn’t want to decrease chair time and the number of visits to the dental office? Not having to deal with temporaries is great for patients and even better for the dental practitioner. We enjoy not having temporaries coming off or breaking during the night or over the weekend. No unscheduled appointments related to temporaries are needed.

We also intentionally designed our new facilities so that our lab and sterilization unit are on display. It’s really something that we’re proud of. We like to showcase our cleanliness, organization and technology. All three of our fastmill.io™ In-Office Mills along with our intraoral scanners can be easily viewed by everybody that’s coming in and out of the clinic. We even invite patients to come and watch their crowns being milled.

MILLING AWAY

I have used CAMouflage® NOW and Obsidian® Milling Blocks, but the material we use the most is BruxZir® NOW. I am also very excited about being able to mill screw-retained implant crowns with BruxZir NOW SRC Milling Blocks. This will decrease our lab costs, increase practice efficiency and reduce delivery times for our patients.

We use our mills mostly for posterior cases. We do mill anterior crowns, but for highly esthetic, complex cases in the anterior, we typically send them to the lab. Nevertheless, I think that our crowns are turning out great straight out of the mill, and my associate, Dr. Kishan Patel, has gone to the Glidewell campus to receive advanced training in esthetic design with chairside CAD/CAM.

After this advanced training, we recently completed a 28-unit full-mouth rehabilitation for a patient who flew in from Florida. We milled and sintered everything overnight and delivered all the crowns in just 24 hours.

MULTIPLE MILLS MULTIPLY REVENUE

By telling the patient they will not have to deal with an impression, a temporary or a second visit, case acceptance has increased. And having three mills in our office almost ensures that we always have one mill available to start same-day treatment, which we offer as frequently as possible.

We have a thriving practice that grows year after year, and last year’s 15% growth was due in part to offering same-day crowns. We did 933 crowns on our three mills last year. My cost per single unit was about $54, which is extremely competitive.

The more crowns you mill, the greater the savings. I also factor in that I’m not flipping the room twice. There’s no need for all the supplies that go into making and cementing a temporary, and I’m often avoiding having to numb the patient a second time. My practice simply wouldn’t be as successful today without my three mills.