Single-Unit Implant Restoration Milled with BruxZir® NOW SRC

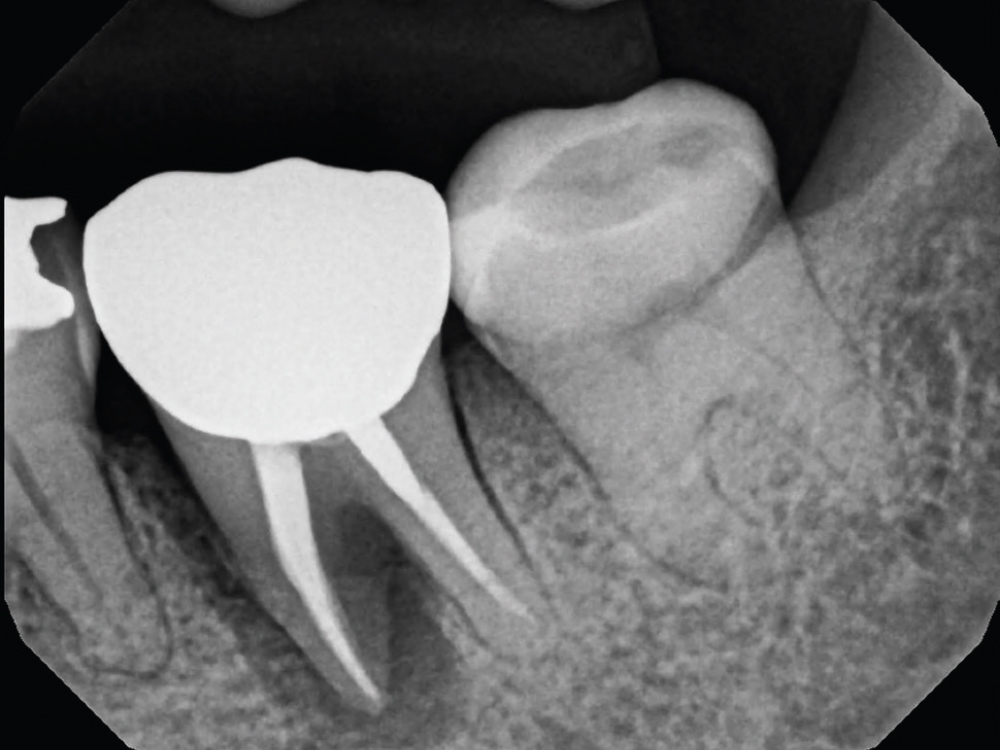

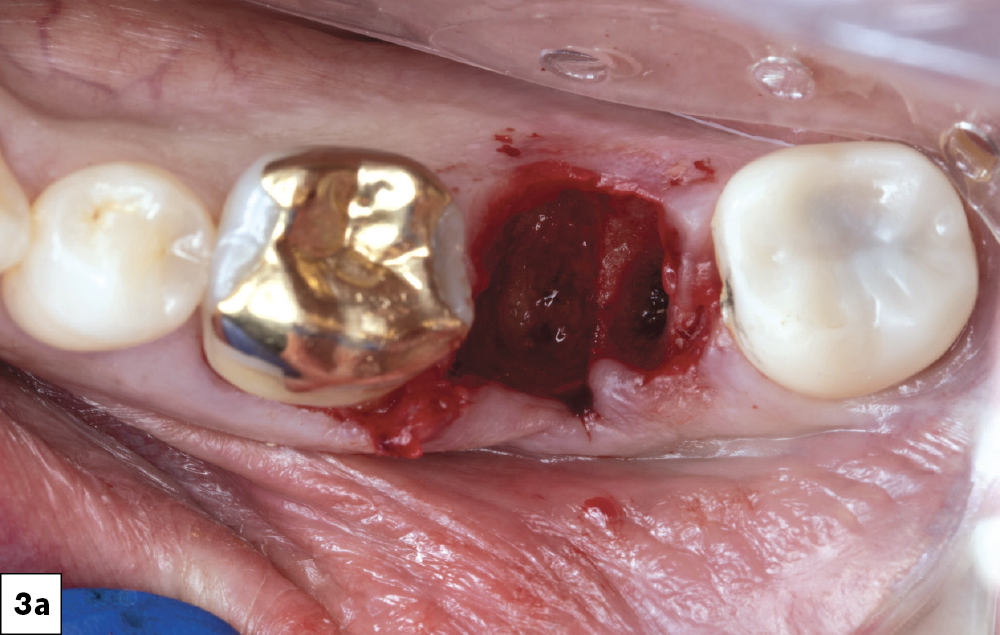

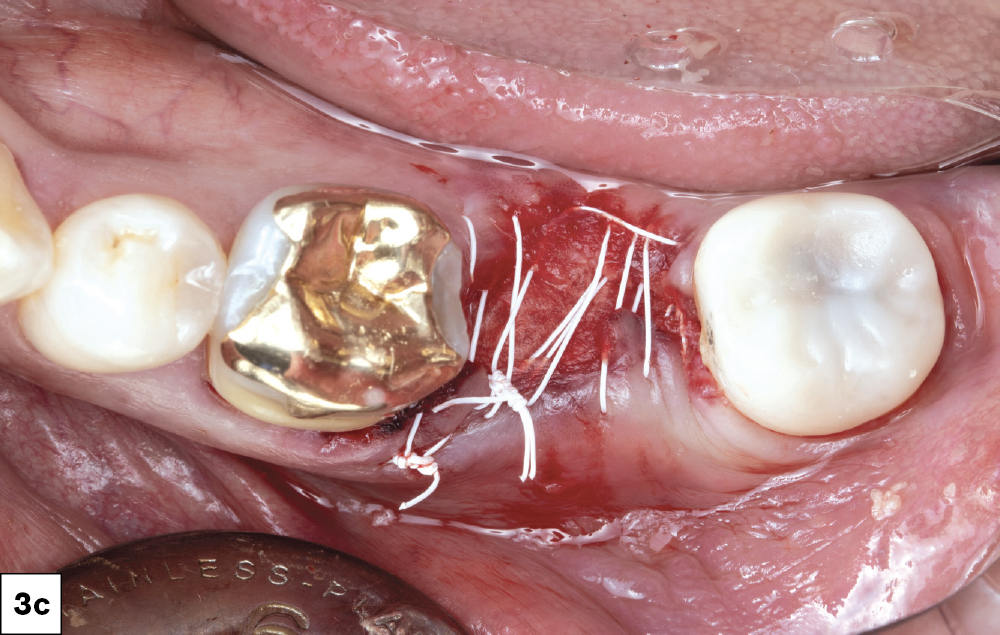

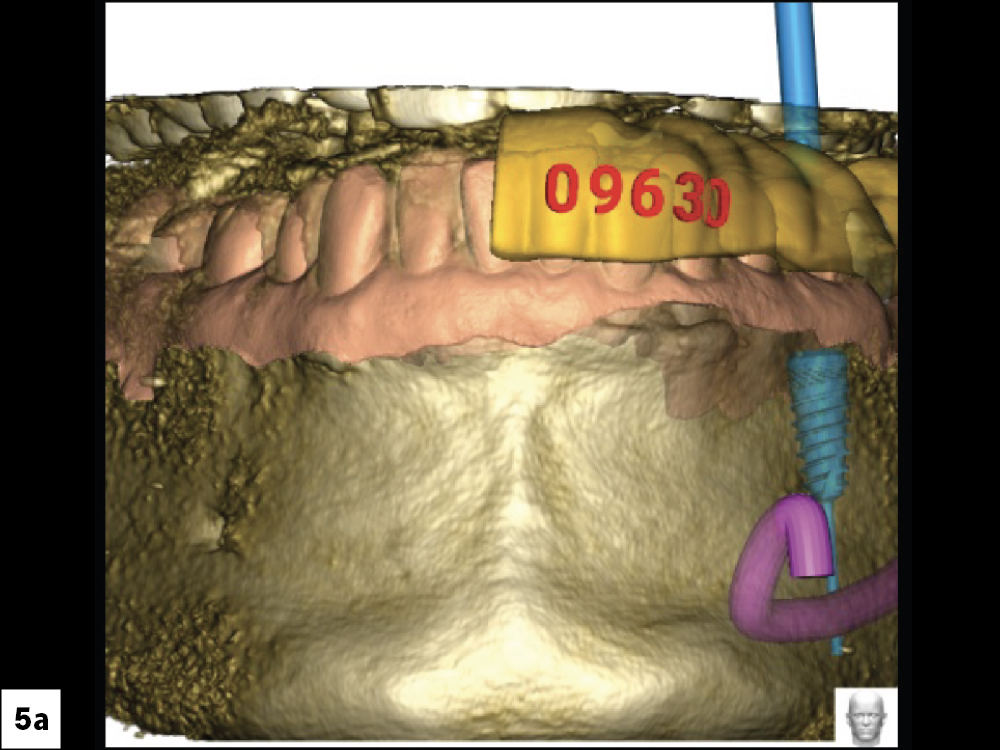

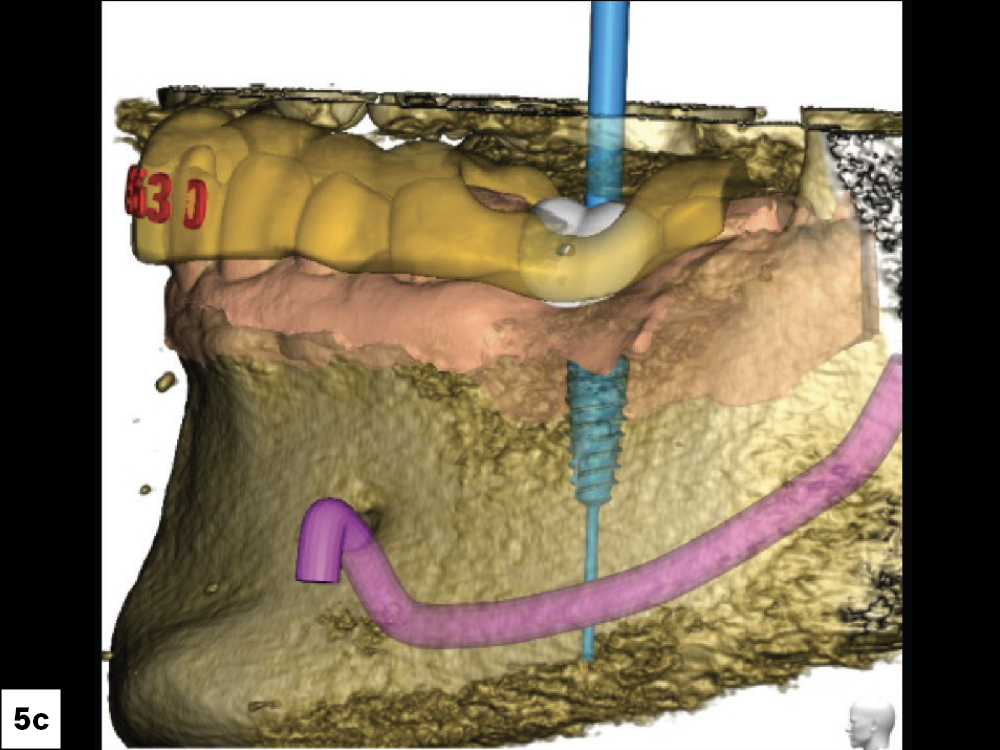

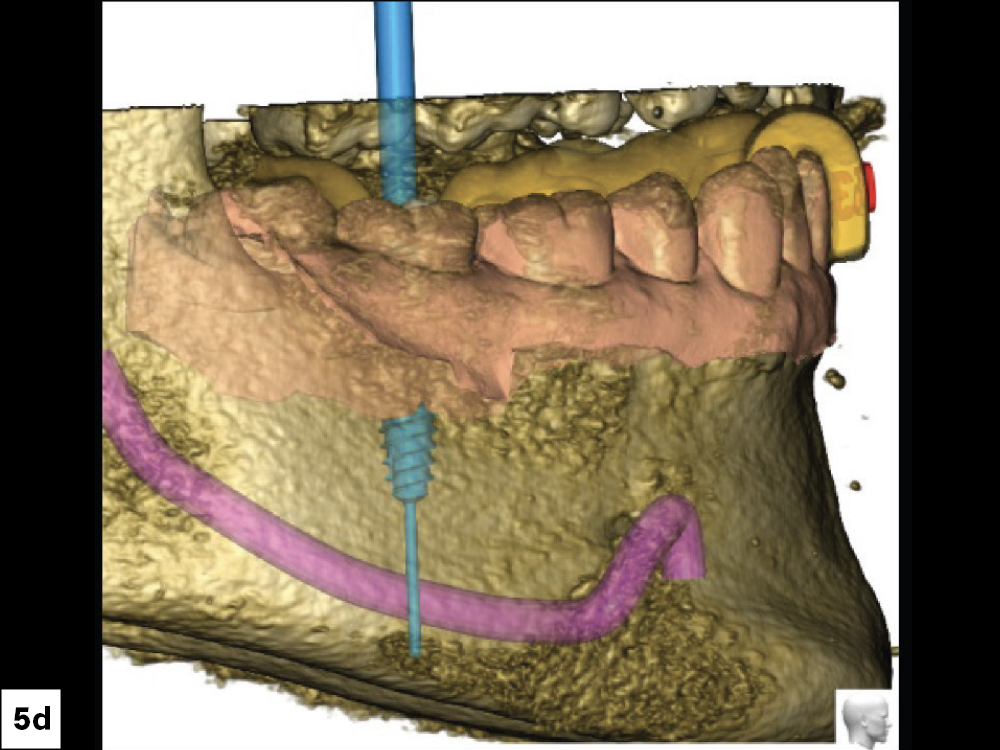

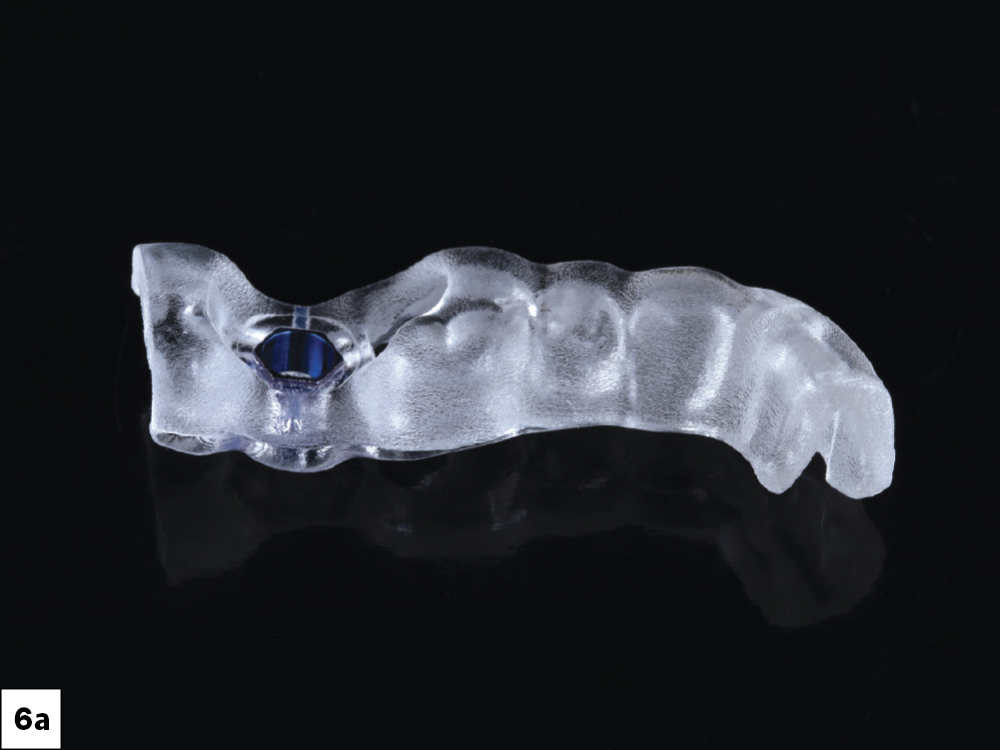

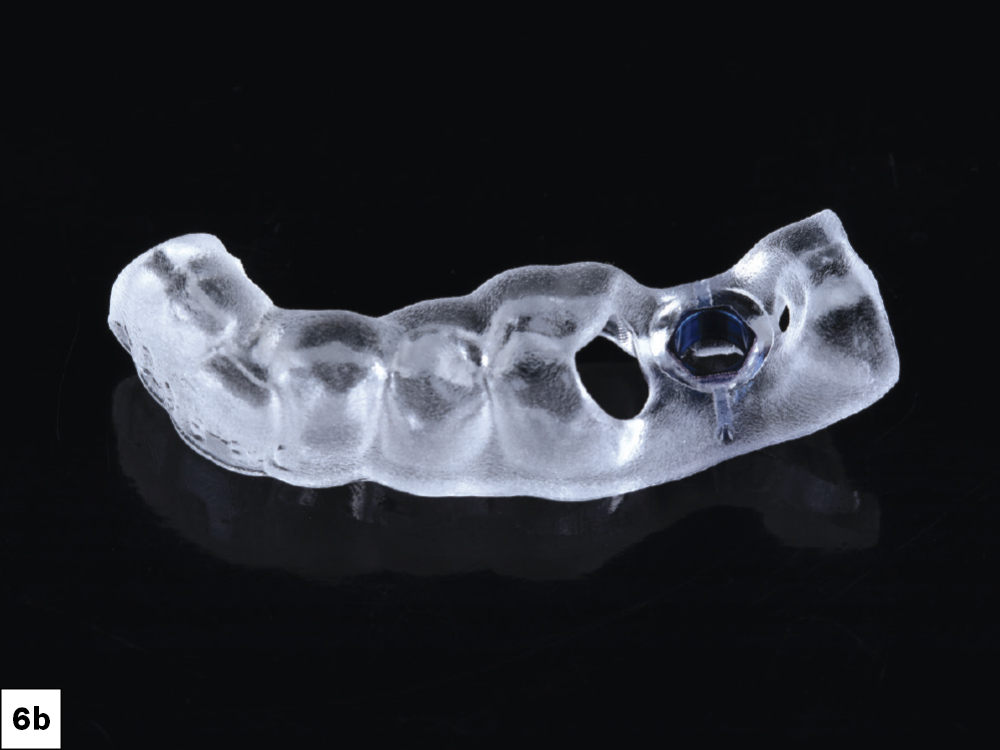

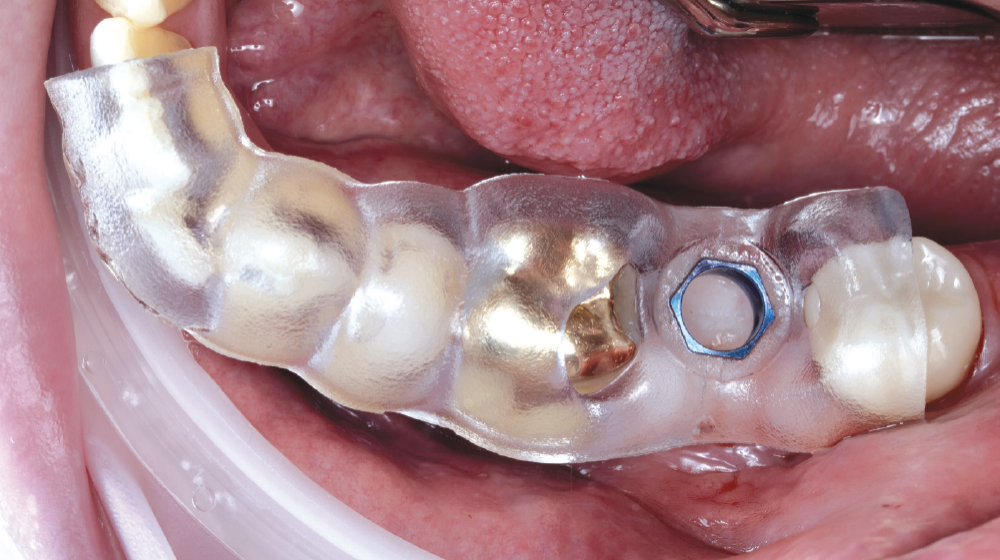

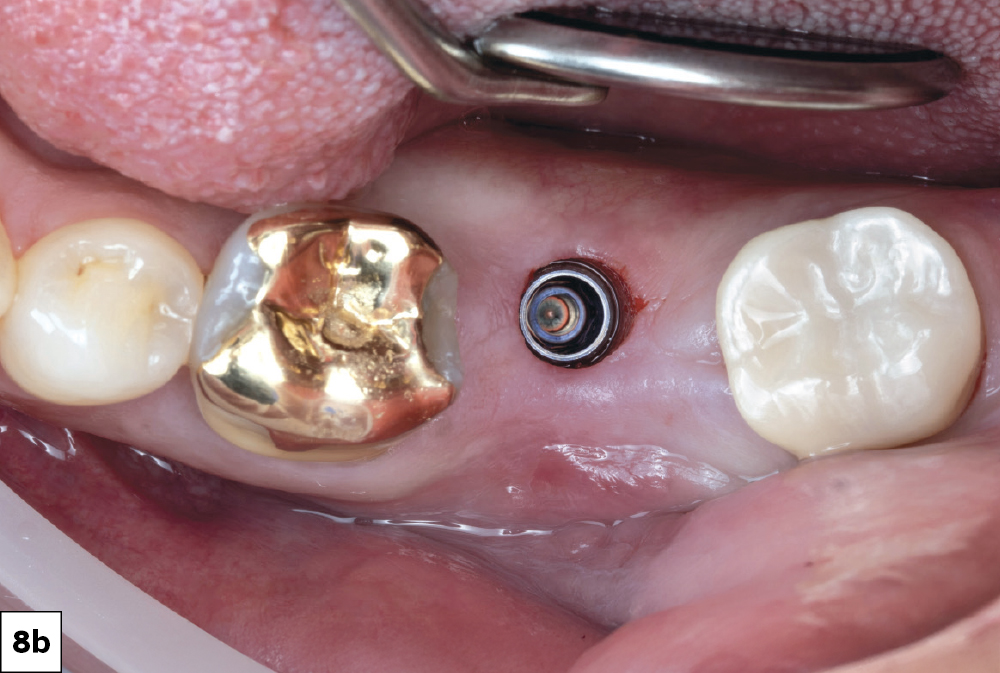

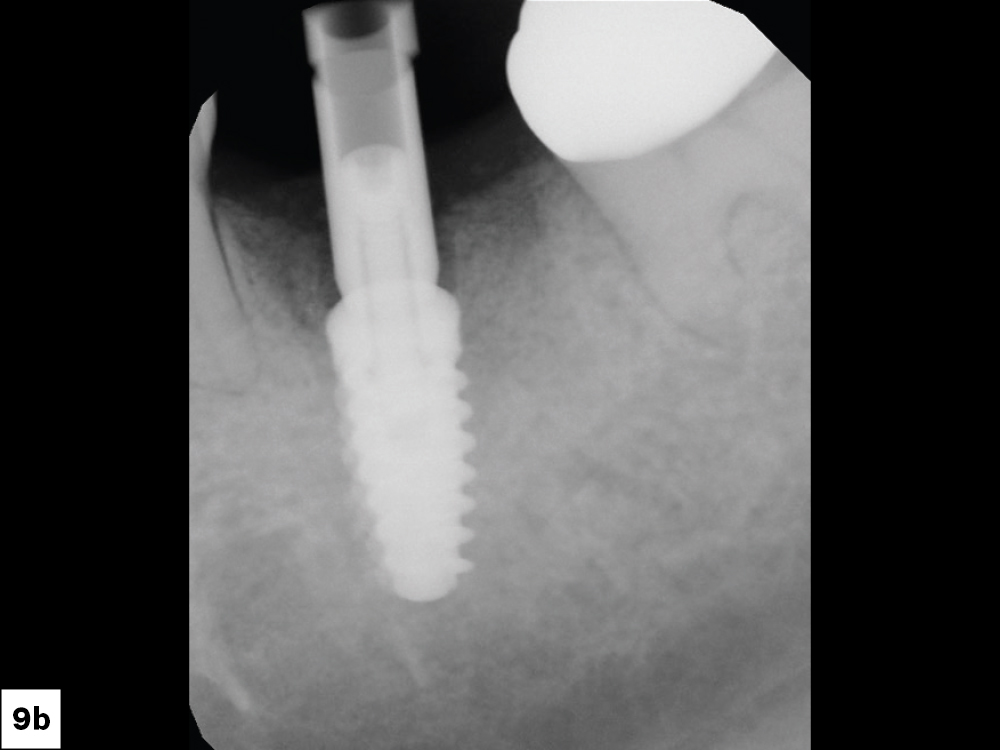

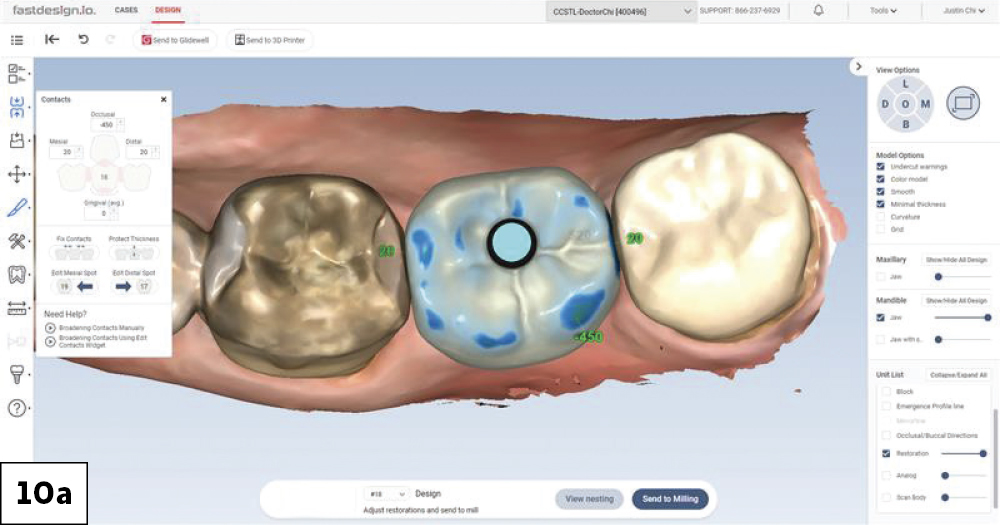

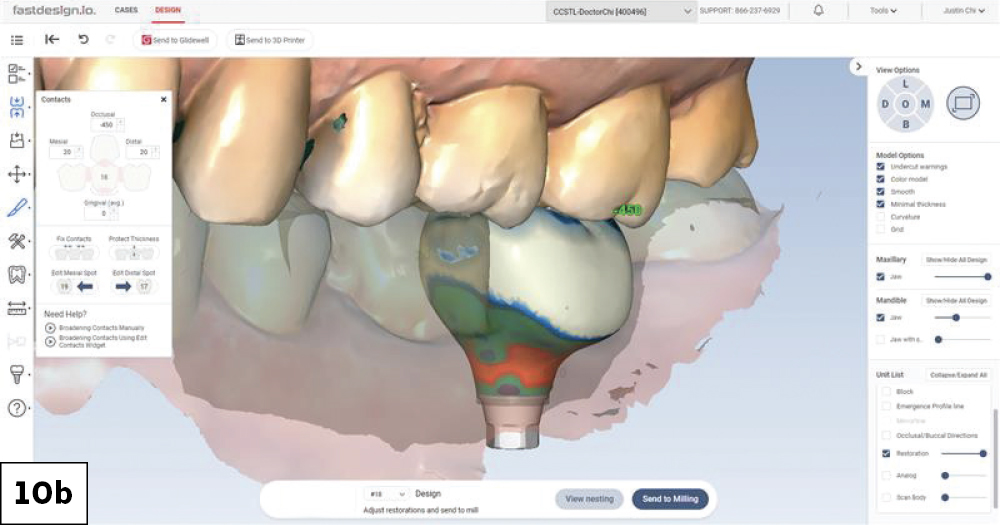

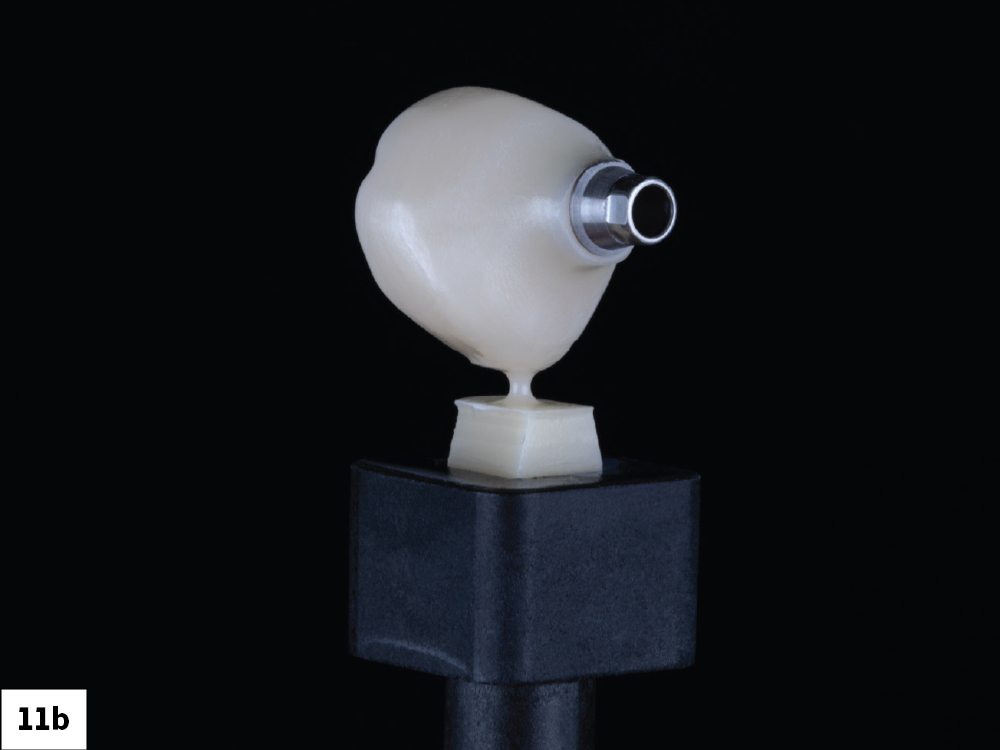

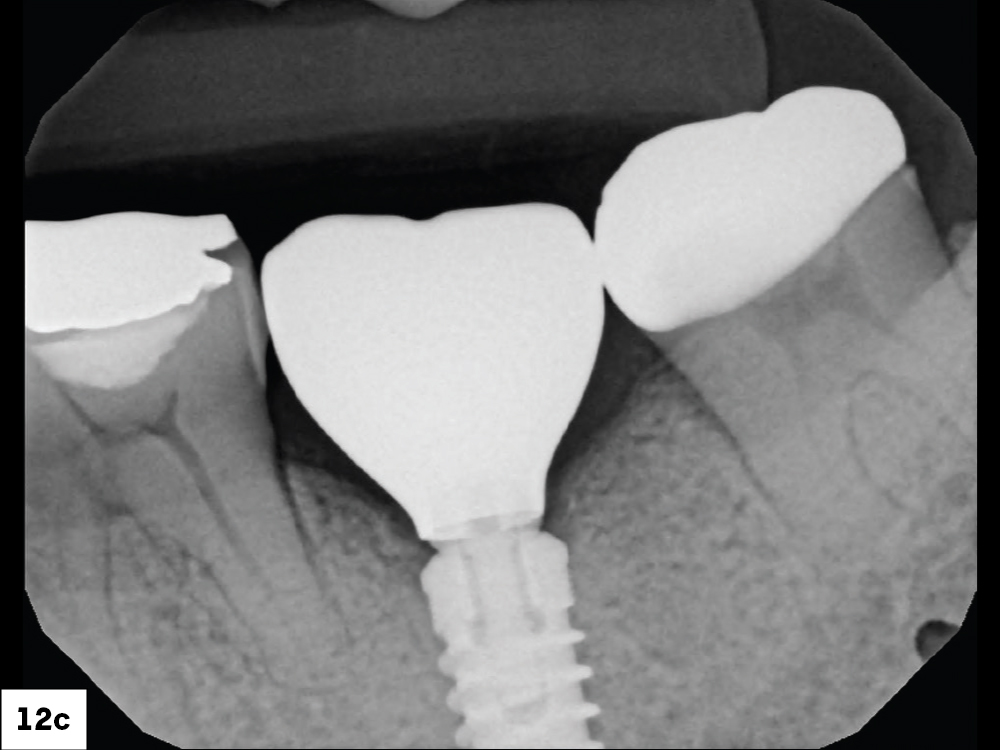

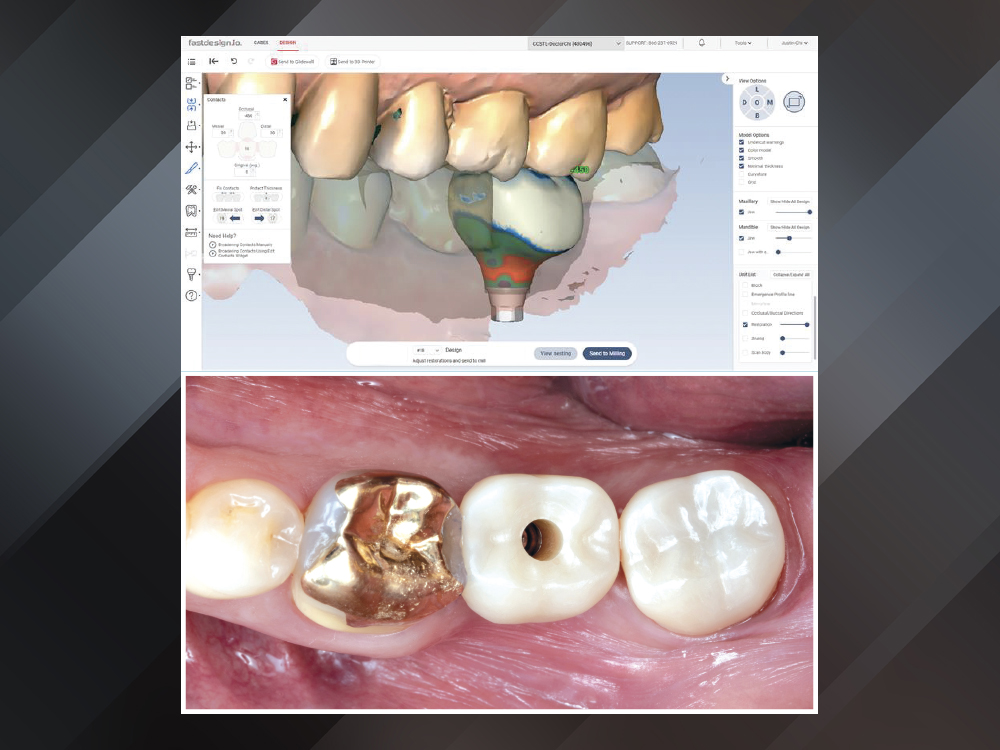

In-office milling is a quickly evolving option for the modern dental practice. With the introduction of a same-day screw-retained option, BruxZir® NOW SRC milling blocks, there’s even more opportunity for optimizing single-unit restoration workflows. In this case study, I’ll demonstrate how this product can be used as part of an efficient workflow for tooth replacement in the posterior. When combined with guided surgery and in-office crown design, this procedure offers reliable results while saving money and significantly cutting down on chair time for dentists.

Case Report

Conclusion

Increased sophistication of in-office crown design software gives dentists more control over restorations they mill in their own practice. More streamlined workflows in surgical and restorative phases means more predictability, repeatability, and long-term success for these essential procedures. By reducing the likelihood of surgical errors with guided implant surgery and cutting down on in-lab working times with in-office milling, clinicians can provide great services while continuing to increase revenue.