A New Option for a Full-Arch Fixed Restoration (1 CEU)

The treatment concept commonly known as “All-on-X” now celebrates 25 years of successful usage. This concept employs surgical placement of four or more implants at specific sites and specific angles to support a fixed full-arch restoration.

For typical All-on-X cases, the implants are immediately loaded with a screw-retained converted denture, which provides a stable, esthetic temporary prosthesis.1 Then, the implants are typically evaluated three to four months after placement to confirm osseointegration, allowing for additional restorative procedures to produce a final, definitive fixed appliance.

There are two disadvantages of the All-on-X technique:

1. Cost: While providing a highly functional and esthetic solution for full-arch restorations, the All-on-X format can be prohibitive financially for many patients.

2. Technical Requirement: The All-on-X format demands a level of accuracy in impression taking that precisely reproduces the positions of all implants in all dimensions. This accuracy is necessary to produce a fixed prosthesis that seats passively on the implant abutments. Failure to meet this standard of accuracy can result in restorative complications. In addition, the All-on-X format typically requires a significant reduction of alveolar bone height to provide sufficient room for the prosthesis.2,3 Clinicians and lab technicians may find this format to be intimidating.

This case report will review and illustrate a novel method for a full-arch restoration using a snap-on, rather than screw-retained, prosthesis. We will explore the advantages of this new format, including a reduced cost to the patient compared to the traditional screw-retained procedure.

CASE REPORT

The patient was a middle-aged female with failing remaining teeth in the mandibular arch. Recurrent caries, fractured teeth, and periodontal deterioration created a hopeless prognosis for these teeth and required full-arch extraction. Prior to being seen in our office, all maxillary teeth had been removed and two implants placed to retain a maxillary overdenture.

The patient declined our recommendation to add more implants in the maxilla to retain a new maxillary overdenture, citing financial reasons. She requested that her treatment be confined to the mandibular arch in the hopes of being able to address the maxillary arch at a later date.

Treatment options to restore the mandibular arch included a conventional removable complete denture, an implant-retained removable overdenture or a fixed screw-retained appliance (All-on-X). Advantages and disadvantages of each option including cost estimates were presented to the patient in detail. The patient agreed to proceed with the following treatment plan:

Phase 1:

- Fabrication of a mandibular immediate complete denture

- Extraction of all remaining mandibular teeth

- Placement of four mandibular implants

- Conversion of the immediate denture to a screw-retained temporary appliance immediately after implant placement

Phase 2:

- Confirmation of proper osseointegration after four months

- Fabrication of final mandibular fixed appliance

Unfortunately, at the surgical appointment to remove the teeth and place implants, the patient noted that she could not afford the agreed-upon treatment plan. She requested that only the extractions and placement of implants be completed at that time. In this revised treatment plan, the patient would use the immediate denture without conversion to a screw-retained prosthesis as the interim solution.

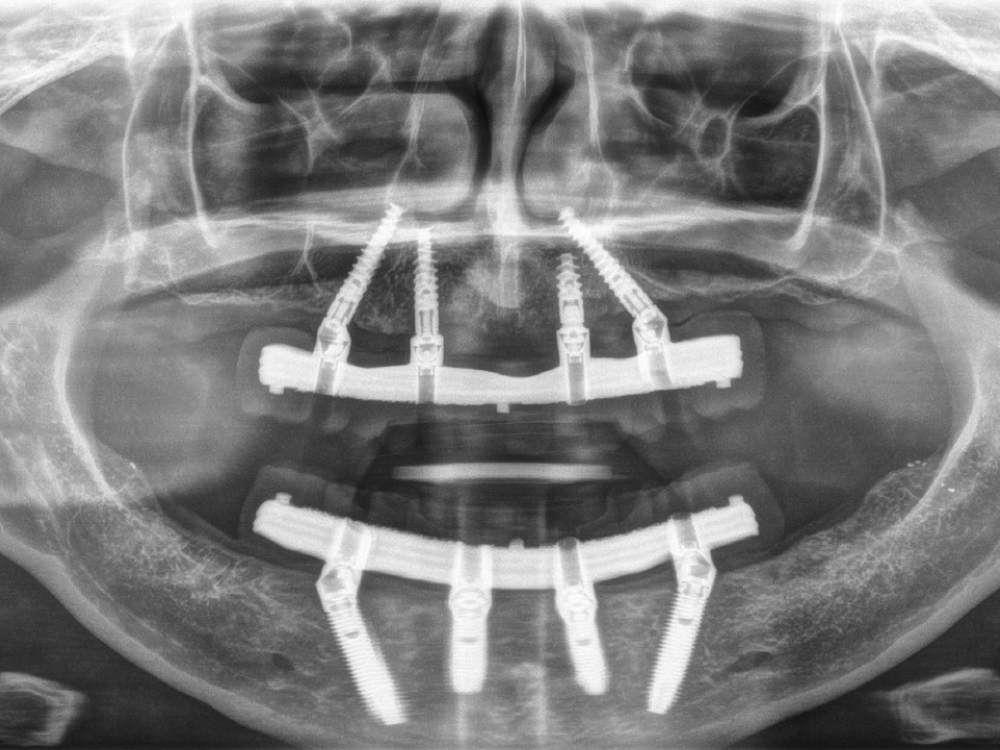

The patient was put under local anesthesia and IV sedation while all remaining mandibular teeth were extracted. Moderate bone reduction with osteoplasty was completed and four Glidewell HT™ Implants (formerly Hahn™ Tapered Implants) were placed (Glidewell Direct; Irvine, Calif.) with healing abutments. The implant sizes included one Ø3.5 x 10 mm, two Ø4.3 x 8 mm and one Ø5.0 x 8 mm. A one-stage surgical implant placement procedure was completed without complications. The Glidewell HT implant system was chosen due to the ease of use, surgical kit features and cost effectiveness.

The immediate denture intaglio surface was relieved sufficiently to allow complete seating over the implants and healing abutments. The denture was relined with a soft liner material. Occlusion and flange areas were adjusted to the patient’s approval prior to leaving the office. We recalled the patient at one-day and one-week intervals to check for any sore spots and to assess her acclimation to the new prosthesis.

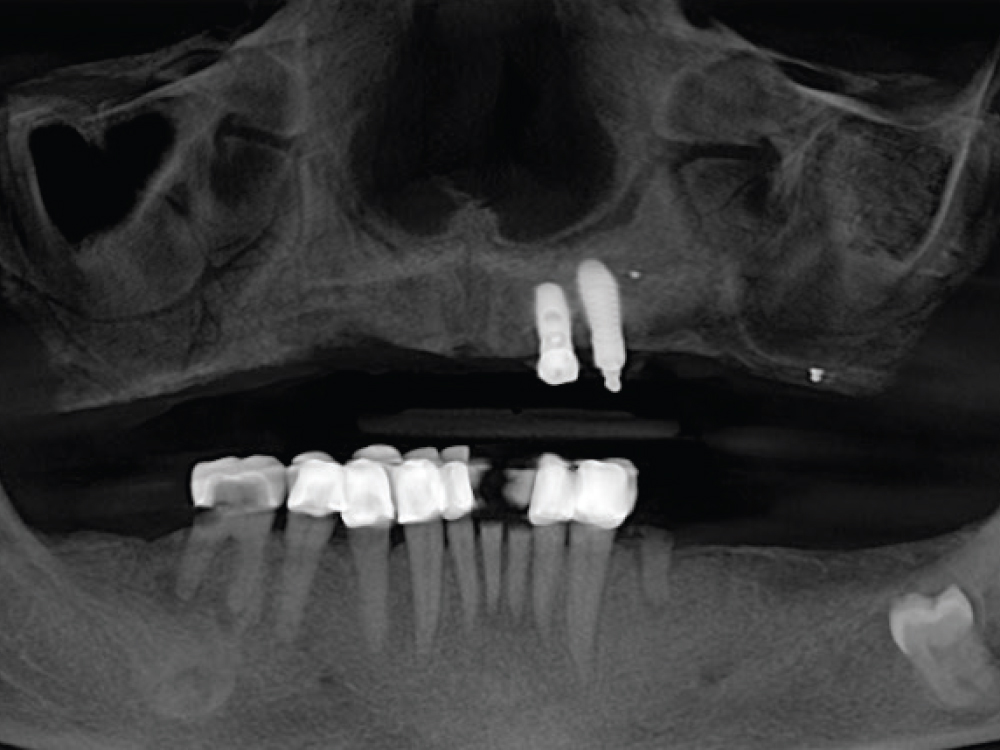

Four months after surgery, healing of the surgical sites was normal with no complaints from the patient. At that time, the patient confirmed her inability to proceed with the original treatment plan for a definitive screw-retained All-on-X appliance due to financial reasons. Fortunately, a new snap-on fixed solution had been recently introduced in the form of Zest Locator Fixed® (Glidewell; Newport Beach, Calif.), an innovative new solution for supporting a fixed implant prosthesis. Using this technology, a fixed prosthesis can be fabricated chairside or by a lab like Glidewell. In this case report, we will outline the chairside procedure for fabricating a Locator Fixed prosthesis for the patient. Among other features, this format provides an appliance that is retentive beyond the patient’s ability to remove it. This allows for normal function without worrying about loosening.

In contrast to the traditional All-on-X format, the Locator Fixed option does not require use of a milled titanium bar but features traditional Locator abutments — thereby significantly reducing the costs of completing the case. The patient was given a fee estimate for converting the immediate denture to a fixed appliance retained by standard Locator Abutments and Locator Fixed Attachments. She found this alternative to be within her budget and approved the treatment plan.

LOCATOR ABUTMENTS

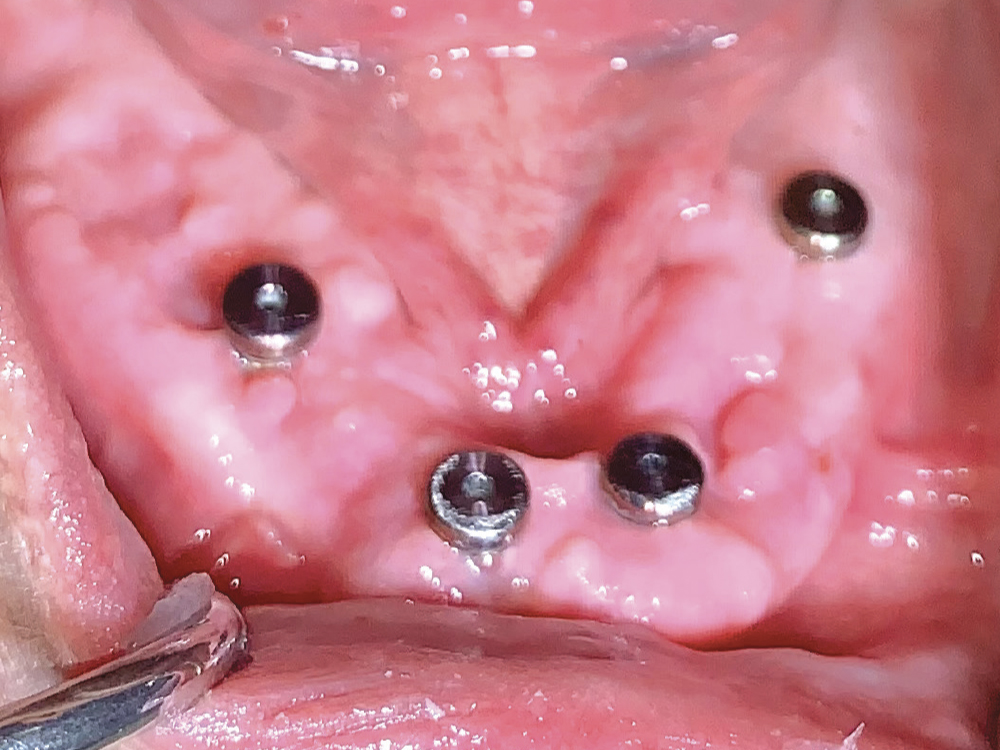

Selection and ordering of the proper Locator Fixed Abutments was made by matching the abutment height to the sulcus depth with the implant type and diameter. In this case, all Locator Abutments were 3 mm heights for the Glidewell HT Ø3.5 mm, Ø4.3 mm, and Ø5.0 mm diameter implants. The abutments were connected to each implant and torqued to 35 Ncm using the Locator insert for the torque wrench.

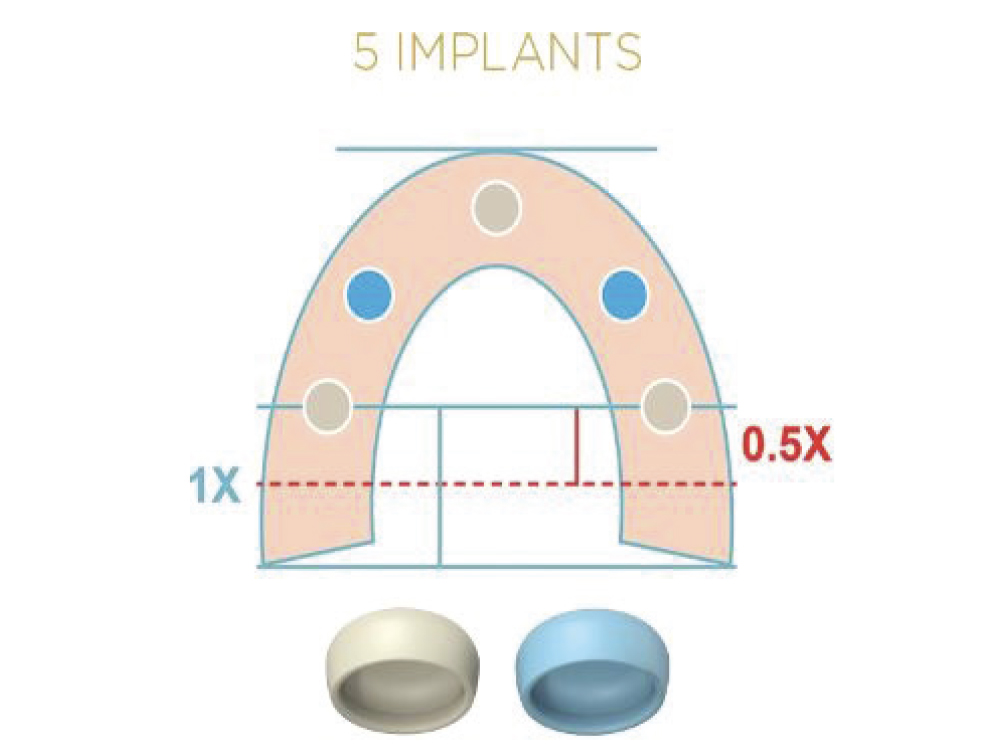

Locator Fixed Attachments are available in three different retention levels and are identified by different colors: green (for four-unit cases), blue (for five-or-more-unit cases mid-arch), and tan (for five-or-more-unit cases in the anterior or posterior). Metal housings with black processing attachments were snapped on the abutments according to the selection recommendations for a case with only four implants. In this case with four abutments, all the implant sites received metal housings containing green attachments.

DENTURE PREPARATION

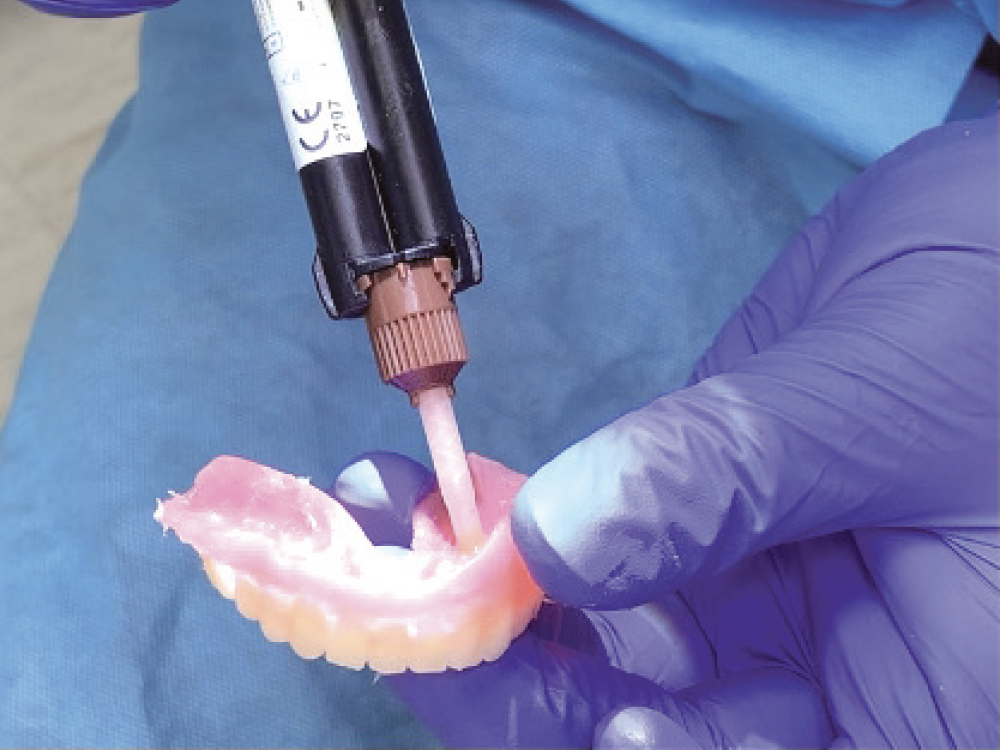

The Locator Chairside Recess Bur provides a correct size opening in the denture base for the Locator Abutment and Attachment dimensions without sacrificing excess acrylic or weakening of the denture. The denture was then seated in the mouth and the patient was instructed to close into complete occlusion to confirm complete seating intraorally at the correct vertical dimension. Lingual vent holes were drilled into the denture base connecting to the access openings using a tapered Locator Chairside Vent Hole Bur (Zest IP Holdings, LLC). White blockout spacers were placed apical to each metal housing to prevent locking the denture in place during the ensuing pickup procedure.

LOCATOR ATTACHMENT CONNECTION OR PICKUP

A small amount of the same material was also injected onto each Locator Metal Housing intraorally. The denture was placed into the mouth and fully seated over all of the metal housings. The patient was again instructed to close lightly into occlusion. This position was maintained for five minutes to allow the acrylic pickup material to self-cure and harden. During this period, a handheld curing light was used to cure through the denture base for a period of 30 seconds at each implant site.

The black Locator Fixed attachments placed intraorally within metal housings provide a relatively light degree of retention. Therefore, removal of the appliance with these attachments connected was accomplished simply by lifting the denture with the handle of a cotton forceps.

CONVERSION OF DENTURE TO LOCATOR FIXED HYBRID

Excess acrylic from the connection procedure was trimmed and polished using lab carbide burs and polishing wheels. Next, the black attachments were removed from their metal housings. The final green attachments were seated into the metal housings using the Locator Fixed Seating and Removal Tool (Zest IP Holdings, LLC).

The flanges of the denture were removed, and the distal portion of the denture prosthesis was trimmed slightly posterior to the distal-most implant abutment and attachment.

In this fashion, the denture modification closely resembled that of a conventional All-on-X format, other than having limited distal cantilever of the prosthesis. The appliance was polished with conventional pumice and acrylic polishing material.

The final Locator Fixed appliance was re-inserted intraorally with hand pressure to provide initial stability. A Locator Fixed Seating Tool was then positioned occlusally over the teeth corresponding to the implant sites. This tool was then activated by cocking and releasing the tool trigger to produce force through the denture base. In this manner, the attachments were thoroughly snapped onto the Locator abutments.

The retention created by the fully seated attachments onto the abutments is significantly greater than with conventional removable overdenture attachments. Because of this high level of retention, the prosthesis will not become dislodged during function, making it a fixed case.

Occlusion, esthetics and phonetics were checked and approved by both the patient and the dentist. The patient was given instructions for cleaning the appliance using a water irrigation system and a toothbrush with toothpaste. The irrigation device provides for effective removal of debris and bacteria on all surfaces of the appliance but especially the traditional hard-to-clean intaglio surfaces. Because hygiene maintenance is often a neglected part of patient instruction for this type of full-arch restoration, the patient received in-depth instruction on how to clean daily with special emphasis on usage of the irrigation device. Water irrigation systems should be dispensed to all full-arch fixed prosthesis patients and considered mandatory in order to prevent the accumulation of debris under the prosthesis.

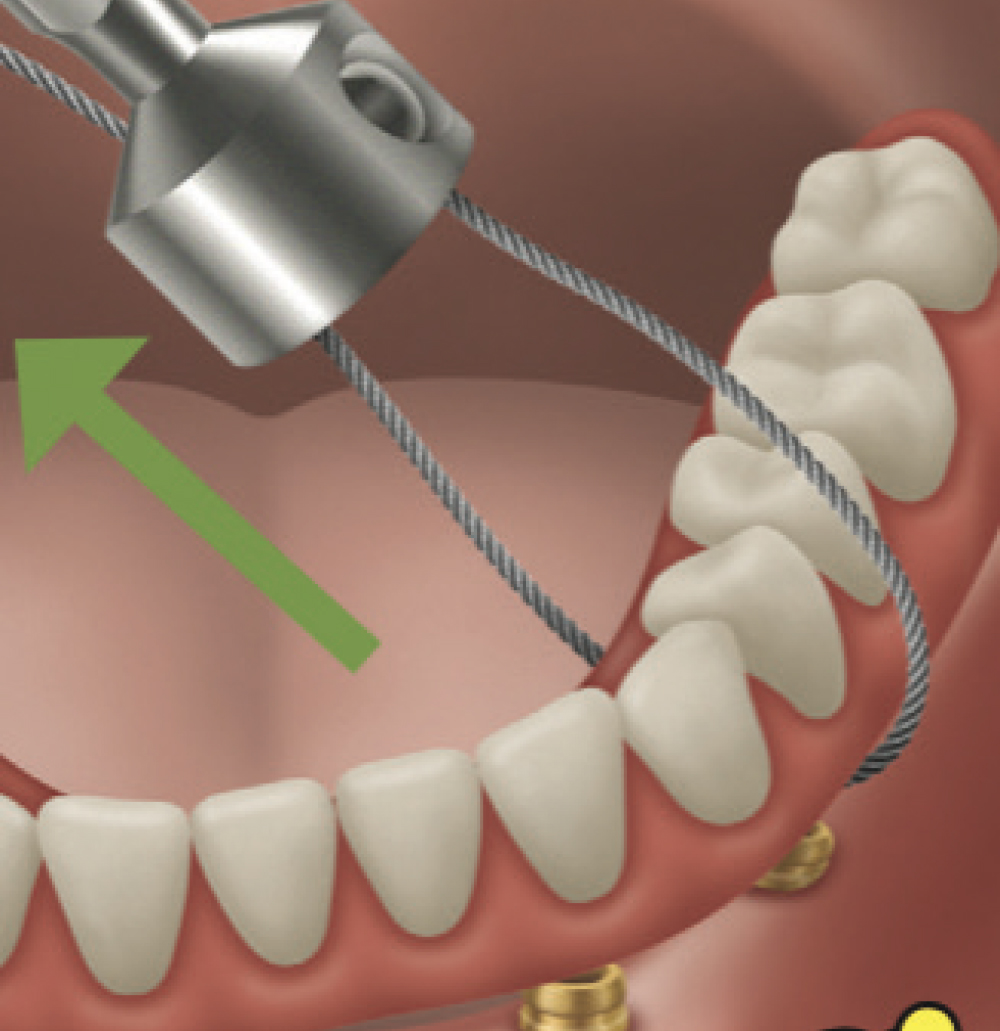

The patient was recalled for regular hygiene evaluation and maintenance on a six-month schedule. Removal of the prosthesis is recommended at this appointment to clean and polish any areas that may harbor debris or be resistant to thorough cleaning. To facilitate removal of the prosthesis, the Locator Fixed removal wire loop was placed under the posterior portion of the appliance to lift the attachment from its abutment retention. The tool handle was cocked and snapped to create the loosening of the attachment. This procedure was followed around and underneath the appliance adjacent to all attachments, resulting in its removal from the mouth.

CONCLUSION

The patient was completely satisfied with the function, esthetics and phonetics of this conversion to a Locator Fixed Prosthesis. This represents a novel alternative to the more costly and demanding technique required from the traditional milled, screw-retained All-on-X format. While the traditional technique is a proven and popular option for full-arch restorations, the Locator Fixed procedure can provide an excellent choice for patients and clinicians who desire its advantages.

For lab fabrication of this restoration, Glidewell offers a wide range of Locator Fixed Prostheses so you can serve patients across the economic spectrum. To learn more, visit glidewell.com/locator-fixed. To purchase Locator Fixed products for chairside fabrication, contact Glidewell Direct at 888-303-3975 or visit glidewelldirect.com.

All third-party trademarks are property of their respective owners.

Available CE Course

References

-

Strong SM. Prosthetic conversion for an interim All on 4 appliance. Gen Dentistry. 2013;61(3):18-20.

-

Scherer MD. Adapting the digital reference denture technique for full-arch cases using a novel fixed attachment system. Compendium. 2022;43(10).

-

Zitzmann NU, Marinello CP. A review of clinical and technical considerations for fixed and removable implant prostheses in the edentulous mandible. Int J Prosthodont. 2002;15(1):65-72.