Simplified Impressions for Complete Dentures

Traditional denture fabrication protocols include a two-step impression procedure with a preliminary impression with alginate in a prefabricated tray. From that initial impression, a custom impression tray is fabricated, border-molded and used for making the final impression with an elastomeric material such as vinyl polysiloxane (VPS).

In our experience, alginate used with a prefabricated impression tray can also be a very successful final impression material. This simplified technique provides important advantages to the dentist and patient.

ADVANTAGES OF THE SIMPLIFIED APPROACH

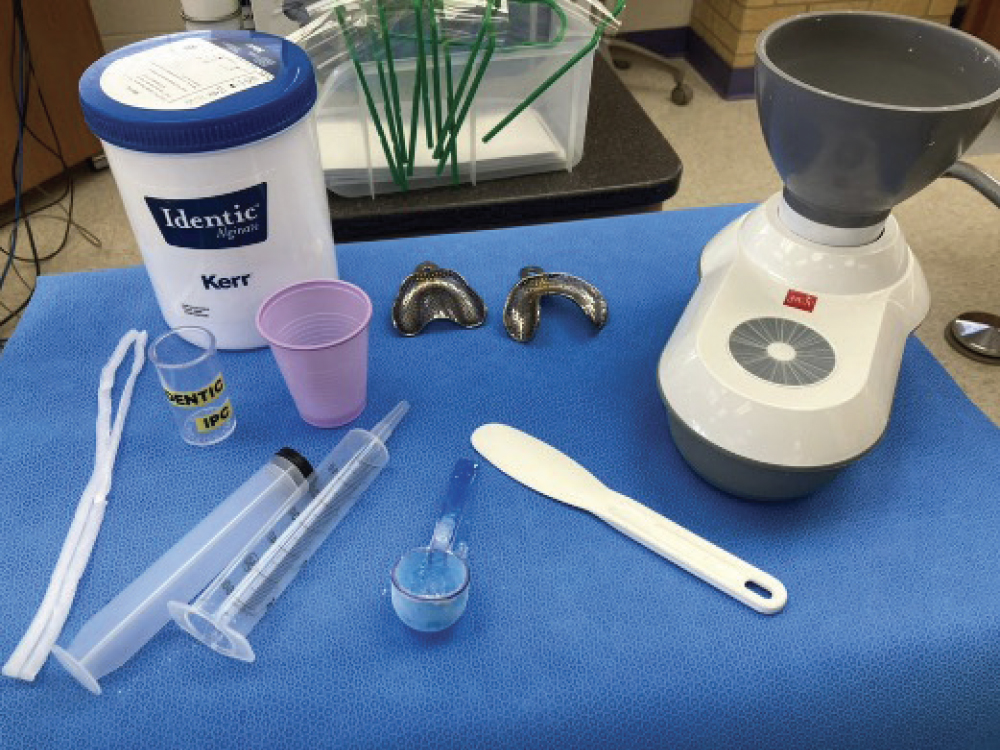

Alginate is inexpensive, readily available and widely used in dental offices. Although VPS impressions may produce a higher level of accuracy, alginate impressions yield results that are sufficient to fabricate dentures with which patients are satisfied.1 Importantly, alginate impression material can be as easily border-molded as VPS material. Using prefabricated trays significantly reduces laboratory material and labor costs, compared to the traditional approach. In the protocol described below, metal STO-K (GC Corporation; Lucerne, Switzerland) edentulous trays allow for easy modification with rope wax. They are also reusable and sterilizable, making the initial investment in their purchase pay off when compared to one-time-use edentulous plastic trays.

With this more efficient, simplified approach, patients receive quality dentures in one fewer appointment, and clinicians save valuable chair time. Why schedule more appointments, spend more time and incur more cost to make a denture the traditional way when the simplified way yields comparable outcomes?

OTHER CONSIDERATIONS

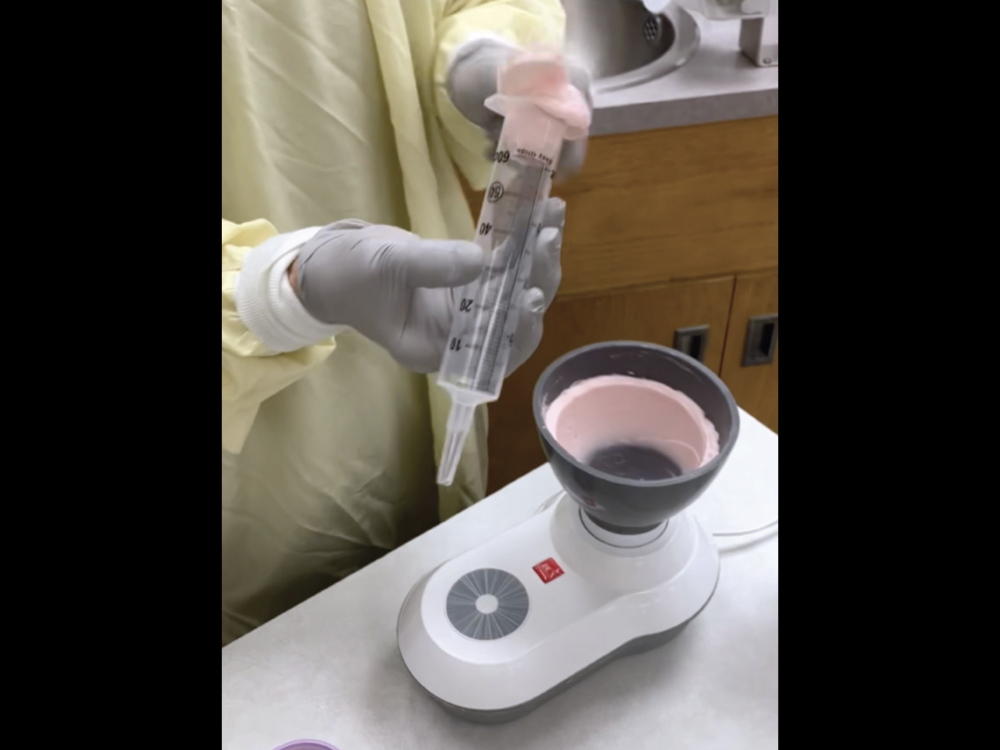

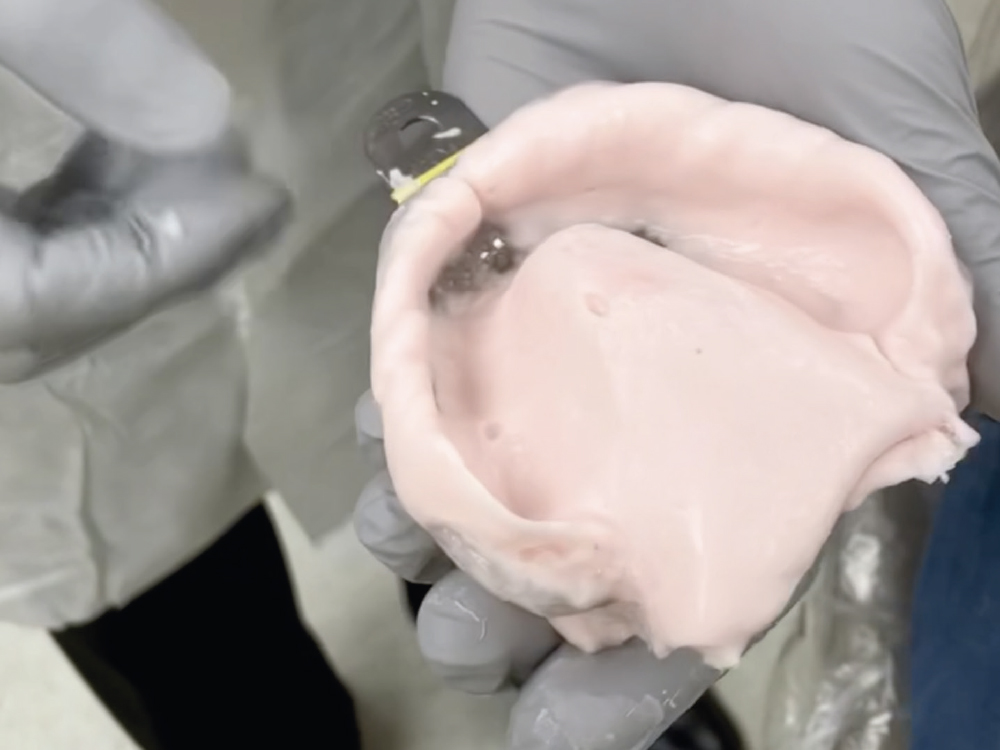

Alginate is normally mixed using a powder/liquid model, which may lead to inconsistency. However, we have found that the inconsistency of hand-mixing can be eliminated by using an electric mixing bowl, like an alginator. Alginate is more viscous than VPS. It is important to recognize that, despite efforts to border-mold while making an alginate impression, overextension or distension of vestibular tissues is fairly common. Accordingly, allowances must be made during denture insertion adjustments. It is also important to note that alginate is not dimensionally stable over time. Therefore, to gain maximum accuracy from an alginate impression, it must be poured within 10 minutes. Otherwise, phenomena like syneresis can cause the alginate to shrink, leading to an inaccurate impression.

Prefabricated metal edentulous trays, such as STO-K, come in different shapes to match different jaw configurations and sizes. However, modifications are often needed to achieve a successful impression. In cases where the flange is underextended, rope wax can build up the length of the tray flange so that alginate is not left unsupported. For patients with a high palate, rope wax can be added to the palatal portion of the maxillary tray to support the alginate impression material and to decrease the risk of a void. On occasion, a patient will present with a jaw shape that does not fit any of the prefabricated tray shapes. In this instance, a custom tray should be fabricated.

THE PROPOSED PROTOCOL FOR SIMPLIFIED IMPRESSIONS

CONCLUSION

There are numerous studies comparing traditional and simplified denture fabrication approaches, where the traditional approach employs a custom tray and VPS model, and the simplified approach employs a prefabricated tray and alginate model. Ultimately, there is little evidence that the traditional method yields better clinical results as measured by patient-reported outcomes.1,2

We may think that we are providing a higher level of care and that we are better dentists for doing so, but the majority of our patients cannot tell the difference between dentures made with either approach. By adopting a simplified impression technique, as described in this article, dentists can increase the amount of time they spend optimizing the jaw position and esthetics of complete dentures.

References

1. ^Carlsson GE. What is the evidence base for the efficacies of different complete denture impression procedures? A critical review. J Dent. 2013;41(1):17-23.

2. ^Ayami J. Kanazawa M. Sato Y. Iwaki M, Akiba N, Minakuchi S. A randomized controlled trial of the different impression methods for the complete denture fabrication: patient reported outcomes. J Dent. 2015;43(8):989-96.