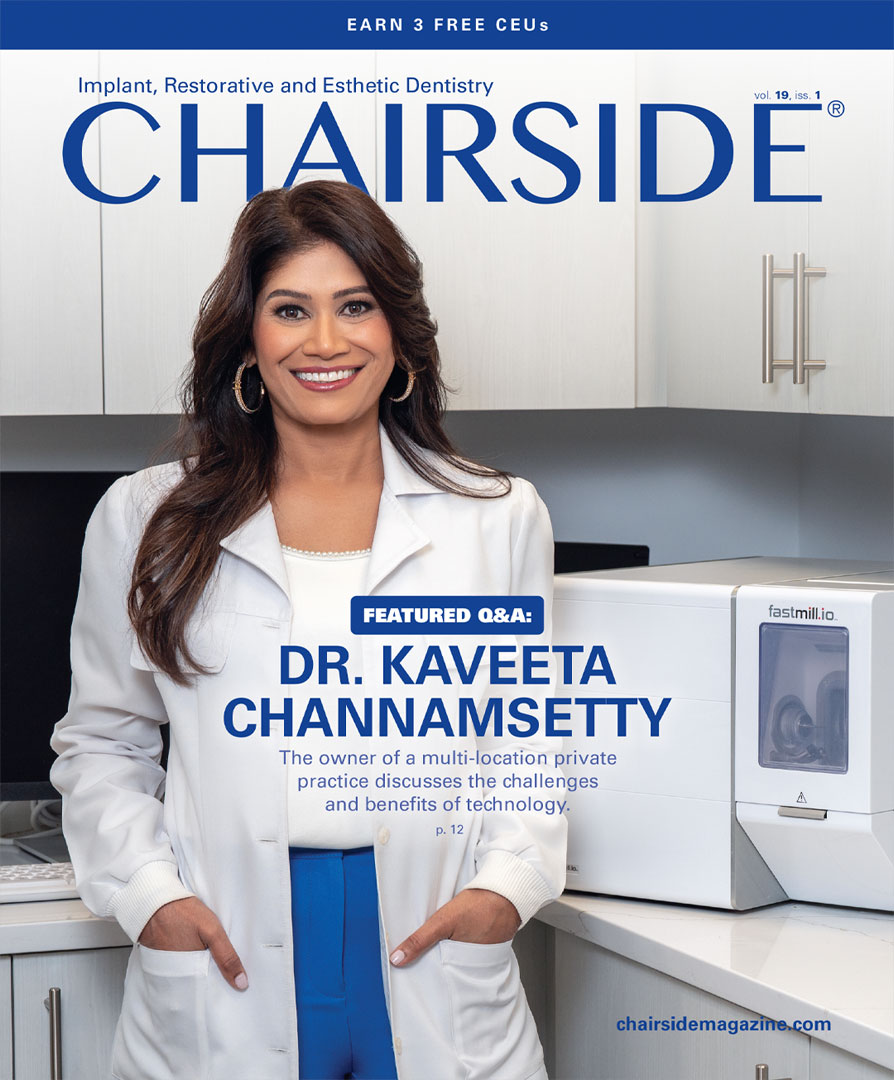

Introducing the Glidewell HT™ Implant System

Since 2015, the Hahn™ Tapered Implant has been Glidewell’s flagship implant system, helping us provide dentists with a premium-quality solution at a fraction of the cost typically charged for comparable implant systems. From the start, Dr. Jack Hahn and I had a mission to provide doctors with an implant system that simplifies implant surgery at a price that makes treatment more viable for general practices. By combining his clinical expertise with the capabilities of our laboratory — which is now armed with data from over two million implant cases — we were able to simplify the surgical and restorative aspects of treatment with cutting-edge design while expanding patient access to implant care with more affordable prices.

Thanks to the success of this implant system — one that is now enjoyed by thousands of dentists across the United States — and the extensive ways Glidewell helps to advance implant dentistry with innovations in lab processes, digital technology and clinical education, I was honored with the 2023 Isiah Lew Memorial Research Award. I am humbled by the American Academy of Implant Dentistry’s decision to recognize this company’s role in the industry, but know our work is far from done. I strongly believe there is more we can contribute, which has inspired an evolution of our implant program for 2024. Today, I’m proud to announce the latest update to our line of implant solutions, which I believe will continue to transform implant dentistry while still adhering to the goal I strived for with Dr. Hahn all those years ago. It is my pleasure to introduce the Glidewell HT™ Implant System.

WHAT IS THE GLIDEWELL HT IMPLANT SYSTEM?

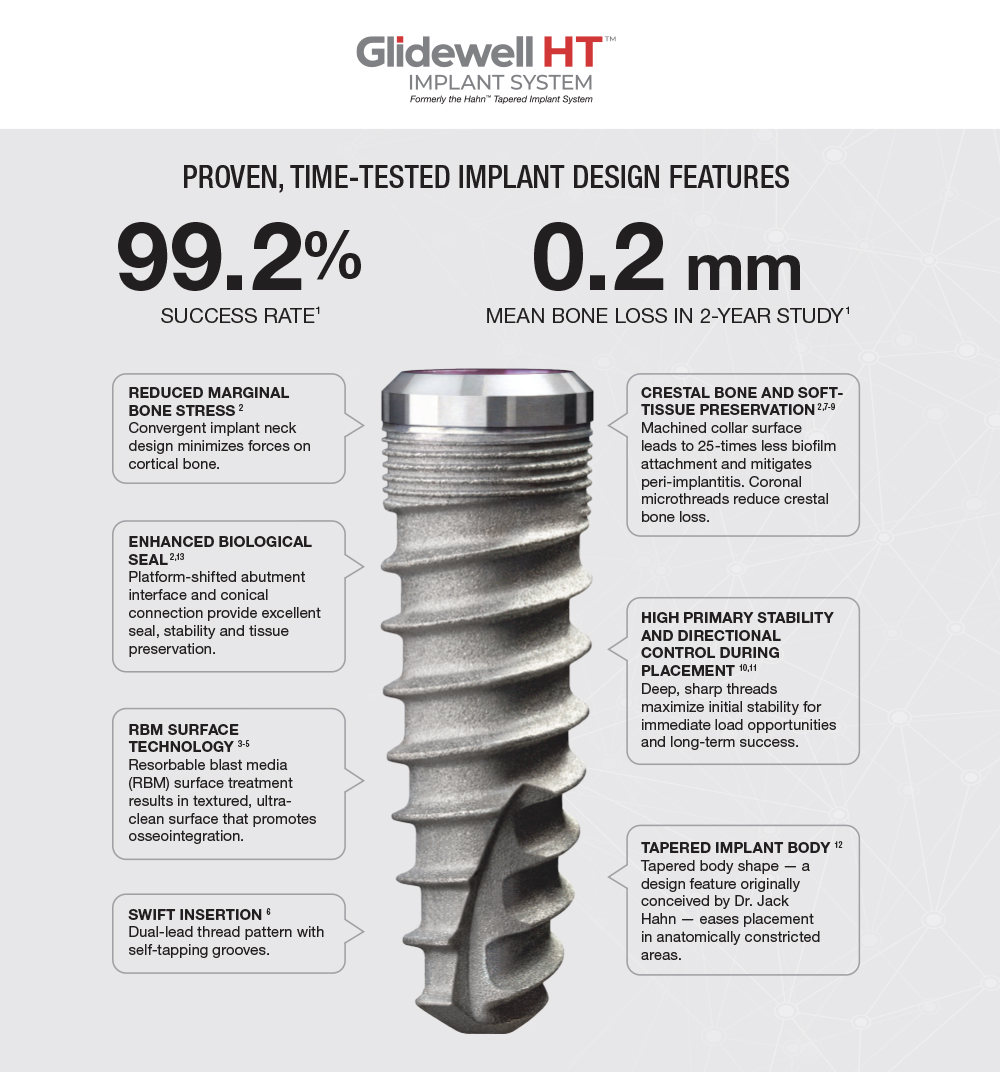

The Glidewell HT Implant System is largely the same premium implant solution dentists have come to know and love as the Hahn Tapered Implant System. The implants are designed with the same aggressive thread pattern, offer the same efficient user-friendly surgical protocol, and are backed by the same unrivaled support from the most experienced dental lab in the world. They also boast the same 99.2% success rate that Hahn implants have demonstrated and are still proudly manufactured from high-strength titanium alloy at our headquarters in Southern California.

WHY THE CHANGE FROM HAHN™ TAPERED IMPLANTS TO GLIDEWELL HT?

Why change a well-known brand that thousands of dentists have adopted in their practices? It comes down to what I believe the Glidewell name means to our implant customers:

- Unmatched expertise thanks to over 50 years of restorative experience

- A “crown-down” approach for a more predictable, esthetic outcome

- Unparalleled lab support every step of the way

For these reasons, we have chosen to lean into Glidewell as the flagship brand name for our implants.

HOW THE GLIDEWELL HT IMPLANT SYSTEM SAVES YOU MONEY

One of the biggest barriers to patient acceptance is the cost of care. For over 60 years, companies like Nobel Biocare® and Straumann® have been notable pioneers in helping advance this industry. Their groundbreaking work and innovations have helped establish dental implants as the first option for tooth replacement, but the millions they spent on research & development — as well as sales and marketing — led them to charge clinicians millions of dollars to use their products, which turned into billions in revenue for them.

Simply put: We believe that the time for dentists to pay hundreds of dollars for an implant is over. With the Glidewell HT Implant System, we aim to free practices from the burden of overpriced implants through everyday surgical and restorative cost savings.

Since Glidewell is the only implant manufacturer that also operates its own full-scale dental lab, we’re able to pass tremendous cost savings on to doctors, while still delivering on quality gained through decades of restorative experience. With the launch of the Glidewell HT Implant System, implants will be priced at only $99. And every time you restore your cases over Glidewell HT Implants with the Glidewell lab, you will automatically save 20% on the cost of your restoration.

In today’s landscape, I believe it’s essential to explore more cost-effective alternatives for the sustainability and growth of implant dentistry without compromising on quality. It’s their new teeth that patients take pride in, not what’s hidden underneath. With the Glidewell HT Implant System, we can provide a proven, FDA-cleared solution that eliminates your implant costs and stands tall against any premium implant — anywhere.

If you have any questions or would like to learn more about the Glidewell HT Implant System, please reach out to our Glidewell Direct team at 888-944-7874. We are looking forward to continuing to service all your implant solution needs for years to come.

The Glidewell HT Implant System is manufactured by Prismatik Dentalcraft, Inc., a wholly owned subsidiary of Glidewell Laboratories. Glidewell HT and Hahn are trademarks of Prismatik Dentalcraft, Inc. All third-party trademarks are property of their respective owners

References

-

Kerr M, Allen B, Park N. Clinical and radiographic evaluation of tapered implants with an aggressive reverse buttress thread and crestal microthreads: a retrospective study. For the full report, visit glidewell.com/ht-2-year.

-

Gracis S, Llobell A, Bichacho N, Jahangiri L, Ferencz JL. The influence of implant neck features and abutment diameter on hard and soft tissues around single implants placed in healed ridges: clinical criteria for selection. Int J Periodontics Restorative Dent. 2020 Jan/Feb;40(1):39–48.

-

Germanier Y, Tosatti S, Broggini N, Textor M, Buser D. Enhanced bone apposition around biofunctionalized sandblasted and acid-etched titanium implant surfaces. Clin Oral Implants Res. 2006 Jun;17(3):251–7.

-

Dohan Ehrenfest DM, Coelho PG, Kang BS, Sul YT, Albrektsson T. Classification of osseointegrated implant surfaces: materials, chemistry and topography. Trends Biotechnol. 2010 Apr;28(4):198–206.

-

Kim YK, Kim SG, Kim JH, Yi YJ, Yun PY. Prospective study of tapered resorbable blasting media surface implant stability in the maxillary posterior area. Oral Surg Oral Med Oral Pathol Oral Radiol. 2012 Jul;114(1):19–24.

-

Abuhussein H, Pagni G, Rebaudi A, Wang HL. The effect of thread pattern upon implant osseointegration. Clin Oral Implants Res. 2010 Feb;21(2):129–36.

-

Hermann JS, Jones AA, Bakaeen LG, Buser D, Schoolfield JD, Cochran DL. Influence of a machined collar on crestal bone changes around titanium implants: a histometric study in the canine mandible. J Periodontol. 2011 Sep; 82(9):1329–38.

-

Ormianer Z, Palti A. Retrospective clinical evaluation of tapered screw-vent implants: results after up to eight years of clinical function. J Oral Implantol. 2008 Jun;34(3):150–60.

-

Ormianer Z, Palti A. Retrospective clinical evaluation of tapered screw-vent implants: results after up to eight years of clinical function. J Oral Implantol. 2008 Jun;34(3):150–60.

-

Torroella-Saura G, Mareque-Bueno J, Cabratosa-Termes J, Hernández-Alfaro F, Ferrés-Padró E, Calvo-Guirado JL. Effect of implant design in immediate loading. A randomized, controlled, split-mouth, prospective clinical trial. Clin Oral Implants Res. 2014 Oct;26(3):240–4.

-

Eraslan O, Inan Ö. The effect of thread design on stress distribution in a solid screw implant: a 3D finite element analysis. Clin Oral Investig. 2009 Jun;14(4):411–6.

-

Alves CC, Neves M. Tapered implants: from indications to advantages. Int J Periodontics Restorative Dent. 2009 Apr;29(2):161–7.

-

Moergel M, Rocha S, Messias A, Nicolau P, Guerra F, Wagner W. Radiographic evaluation of conical tapered platform-switched implants in the posterior mandible: 1-year results of a two-center prospective study. Clin Oral Implants Res. 2015 Jun;27(6):686–93.