Renewing a Smile with the glidewell.io™ In-Office Solution

The introduction of in-office milling was a rewarding experience for my practice. I began with posterior cases and enjoyed the ability to offer same-day crowns while controlling the quality of the restoration.

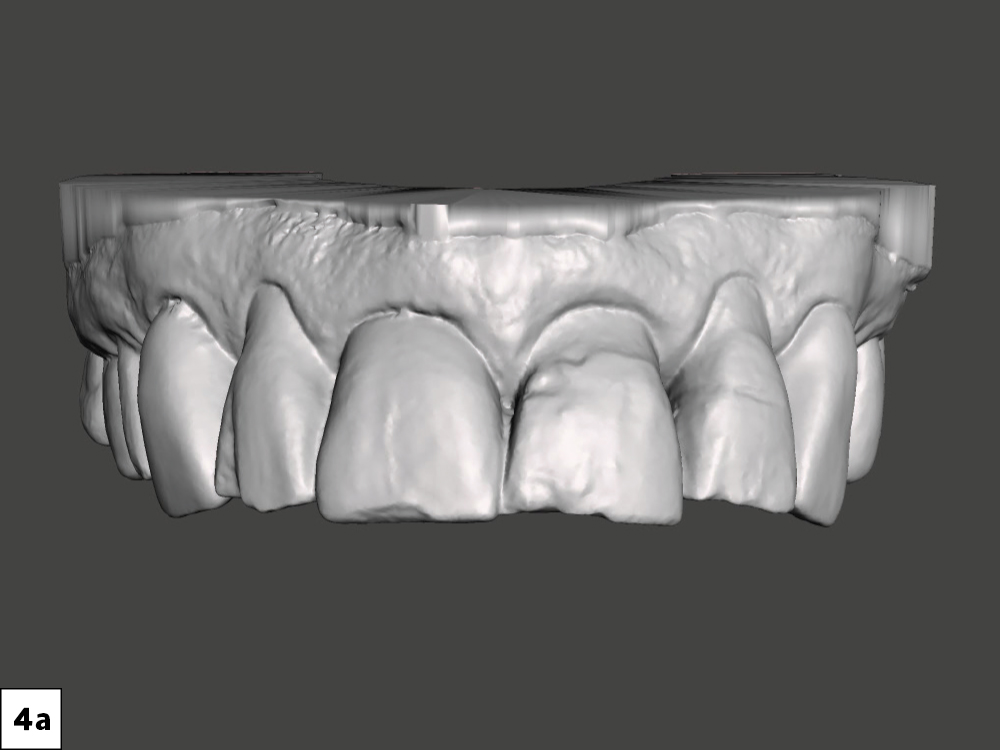

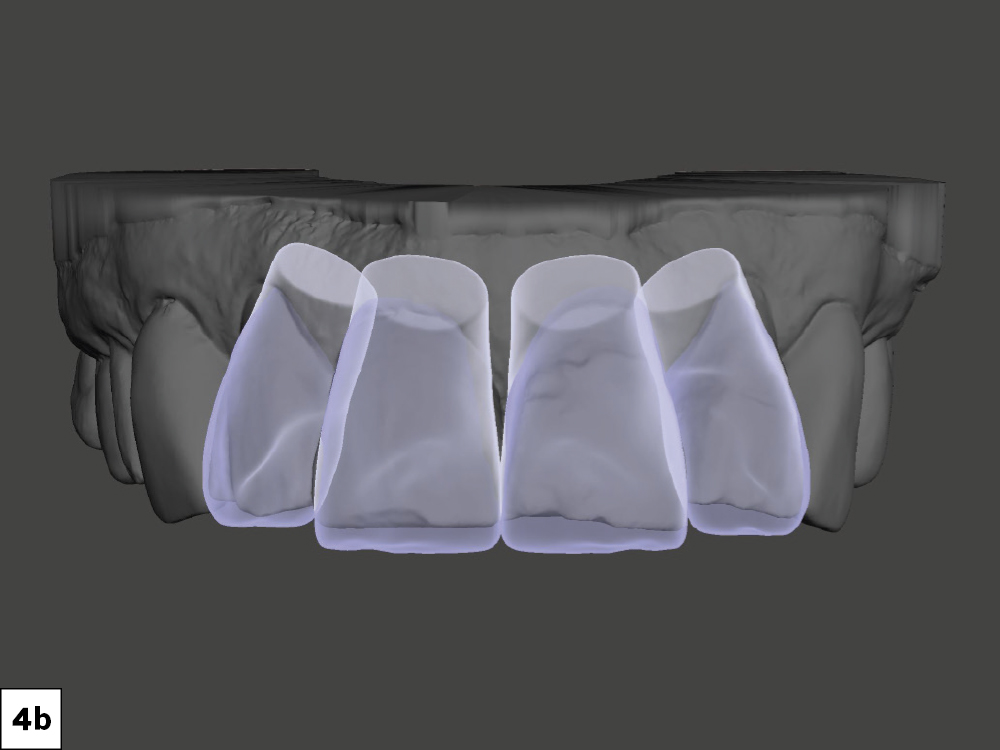

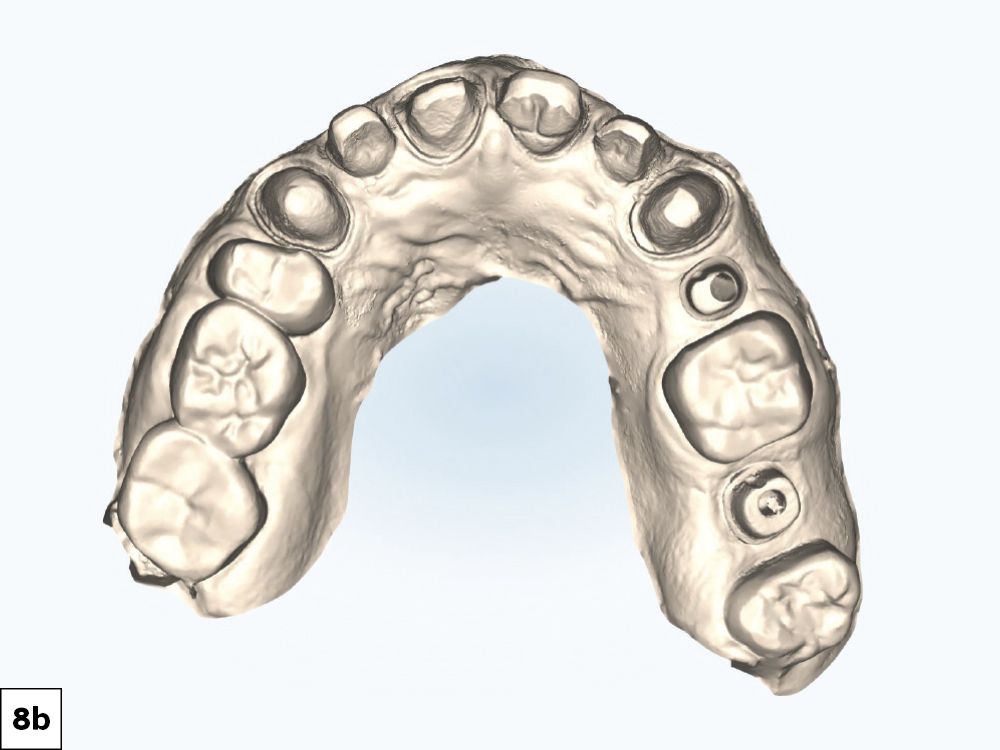

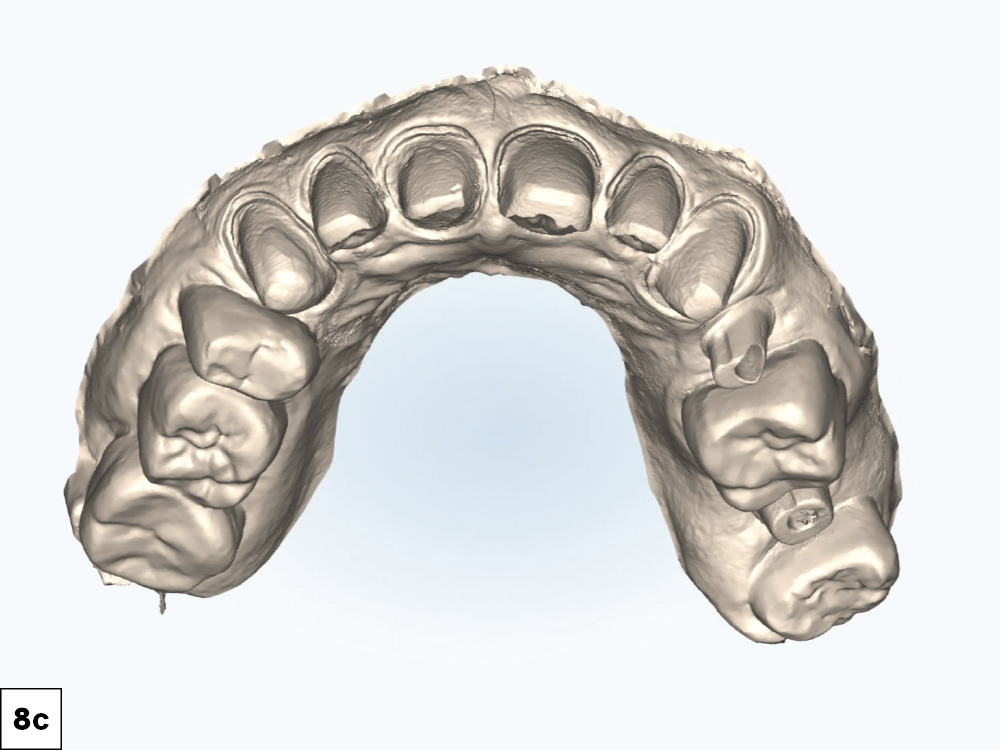

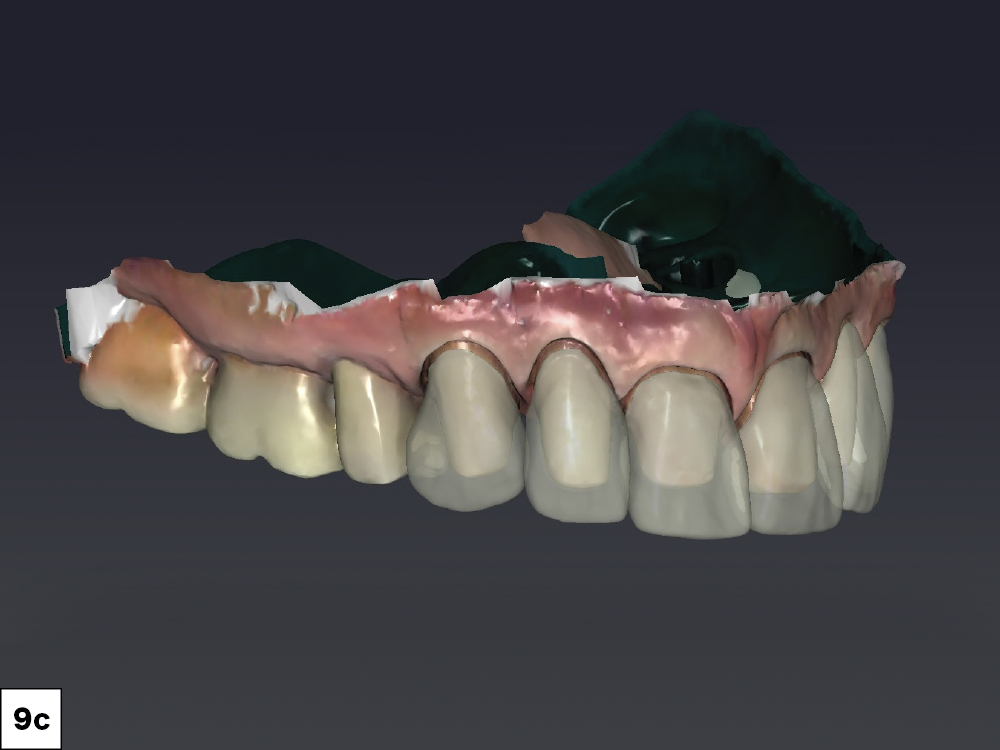

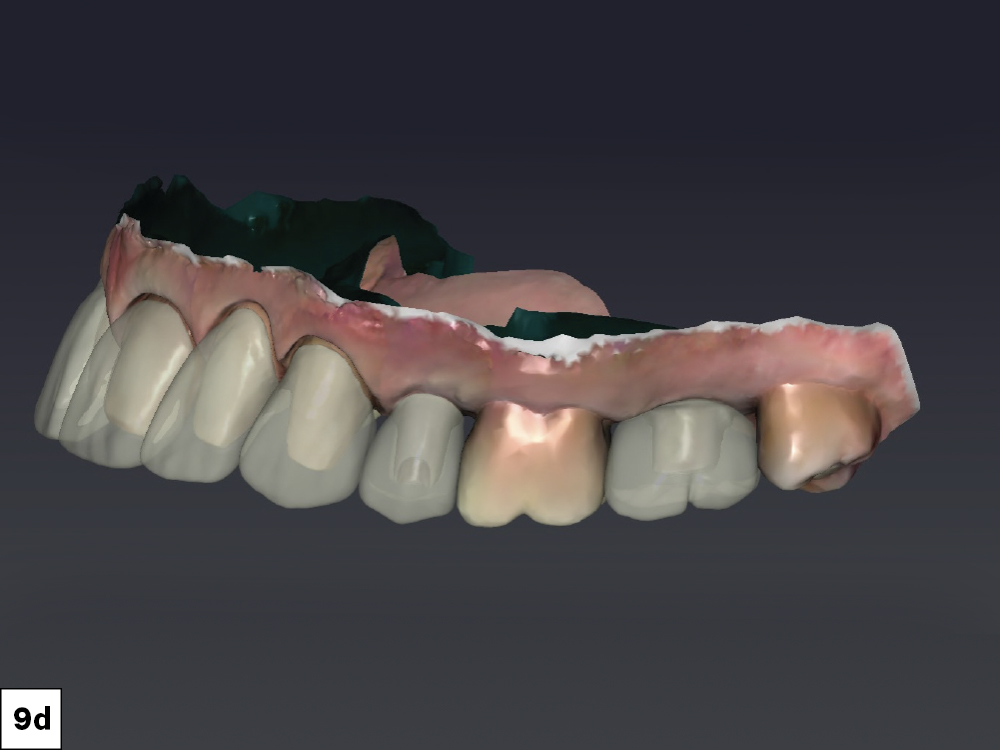

After about a year, I was ready to take the next step and begin milling anterior cases. To this end, I took Dr. Justin Chi’s hands-on advanced anterior course at Glidewell. The course covered the finer points of crown design and characterization, which served me well when this patient sought a remake of his smile.

CONCLUSION

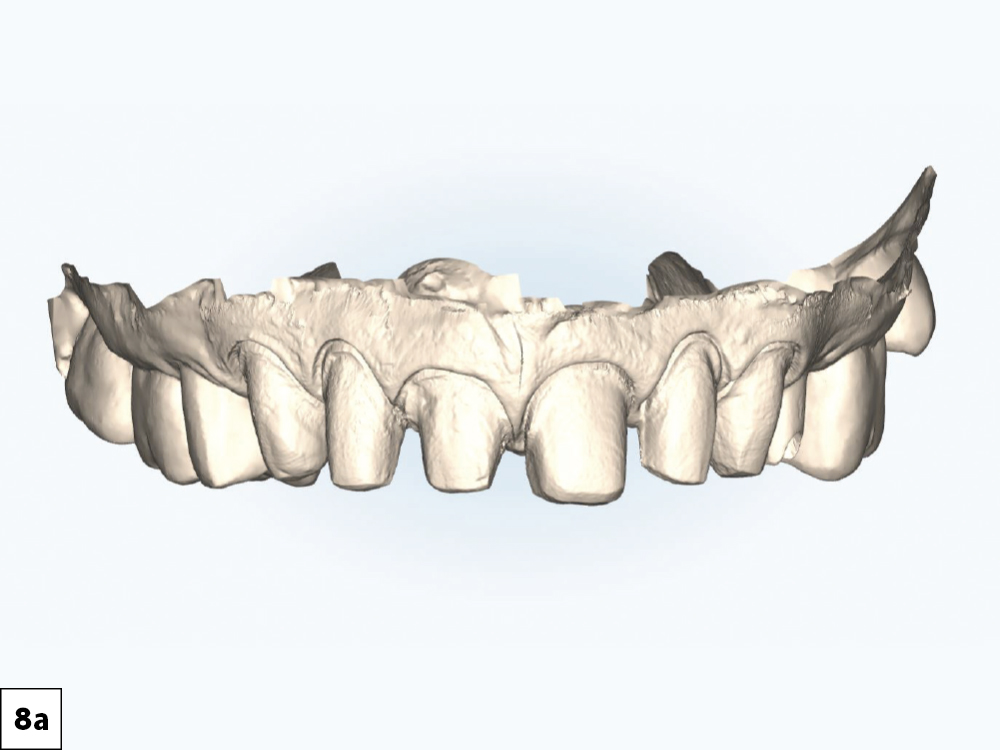

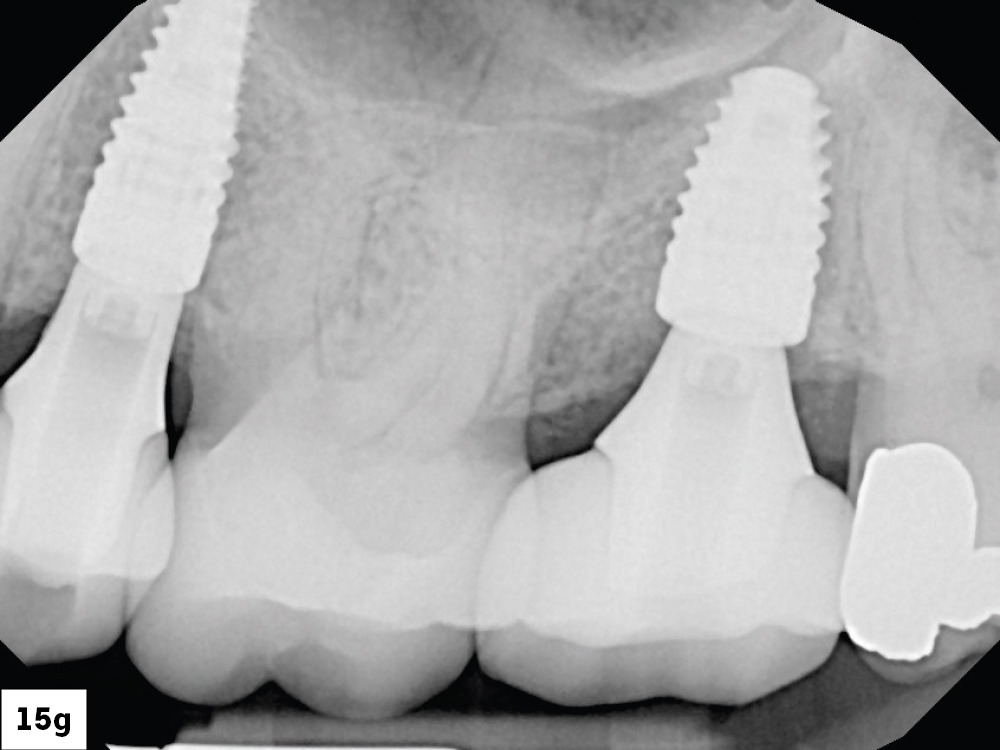

The glidewell.io system helped me turn around a case efficiently and to a standard that satisfied me and the patient. The design process and milling were completed in a day, even with a full clinical schedule. I was able to stain and glaze the crowns between patients while my assistants helped with milling. I was especially pleased with the surface anatomy and texture, which gave the restorations a natural look.

Adding the skills necessary to provide anterior restorations with my mill made a rewarding experience even more gratifying, as I could provide the patient with a high-quality result in a timely manner. Whether you want to start doing anterior cases or stay with the more straightforward posteriors, I recommend glidewell.io In-Office Solution milling to any dentist looking to add another dimension to their practice.