Same-Day Screw-Retained Zirconia Restorations: A Fully Integrated Digital Workflow (1 CEU)

The integration of chairside digital technology has redefined how clinicians approach implant rehabilitation. What once required multiple appointments, provisional restorations, and laboratory coordination can now be completed within a single visit. The convergence of guided surgery, high-accuracy scanning, AI-driven design, and in-office milling has created a workflow that is efficient and predictable in both function and esthetics. A recent case demonstrates this evolution.

CASE REPORT

CASE ANALYSIS

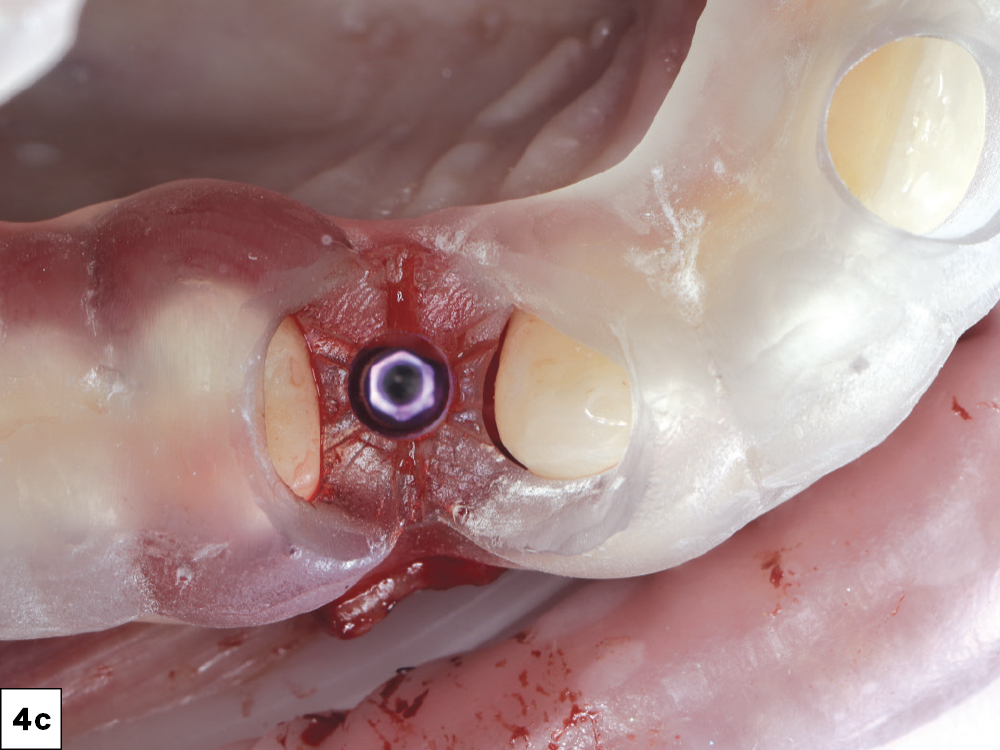

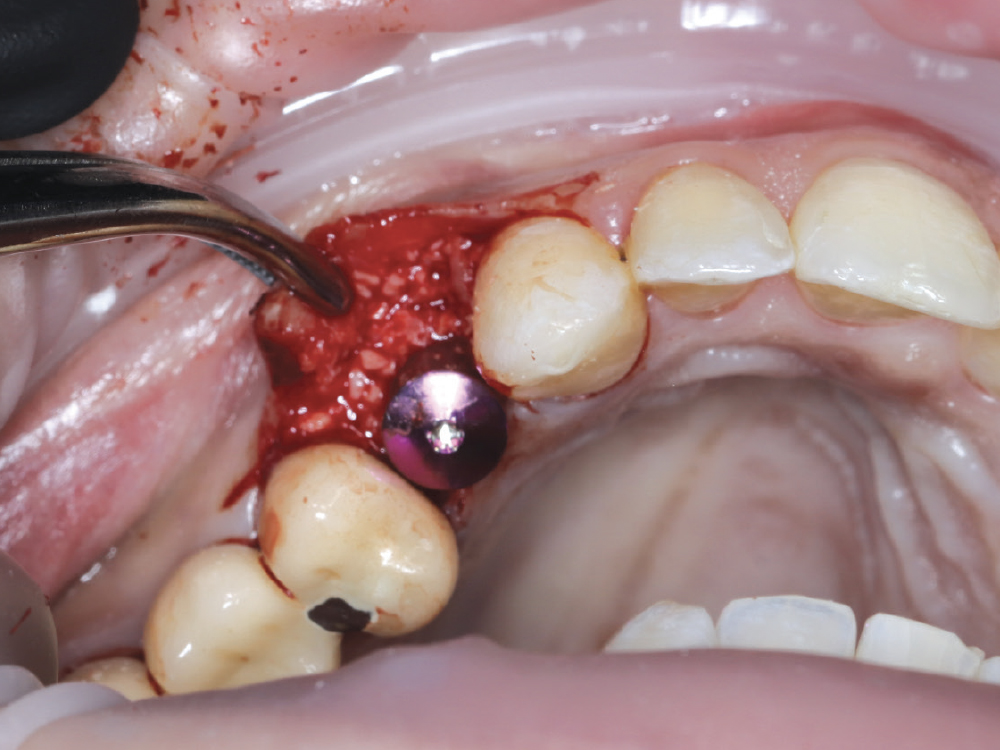

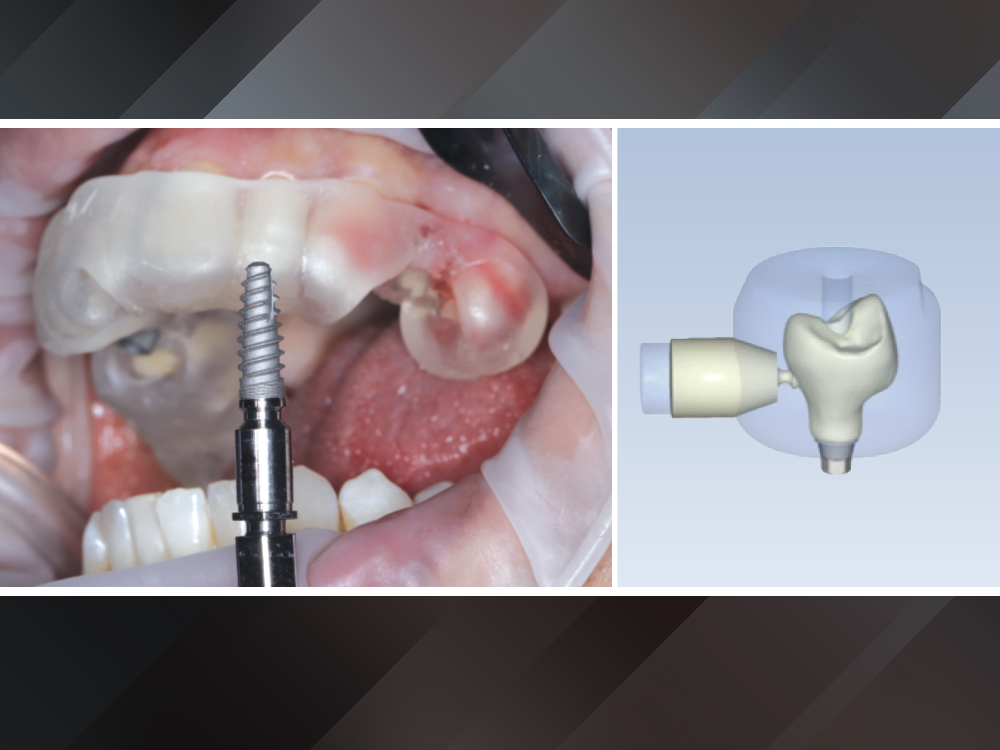

Traditionally, immediate implant cases require interim prostheses fabricated either from a 3D-printed template or from chairside acrylic using a surgical stent. While effective, these provisional restorations demand additional time and offer limited esthetics and strength. They also introduce biologic challenges: repeated connection and removal of temporary cylinders, exposure of healing tissues, and potential disruption of the developing soft-tissue seal. Delivering definitive zirconia restorations at the time of surgery eliminates these intermediate steps and their inherent risks. The peri-implant mucosa can adapt immediately to a stable emergence profile, reducing tissue remodeling and improving long-term esthetics.

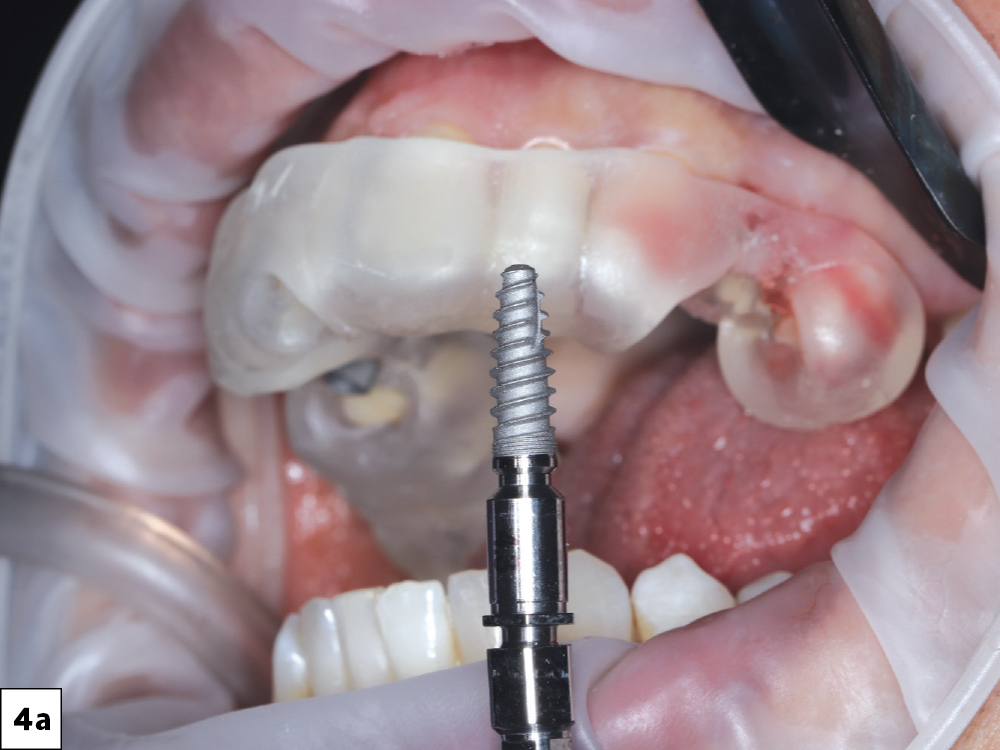

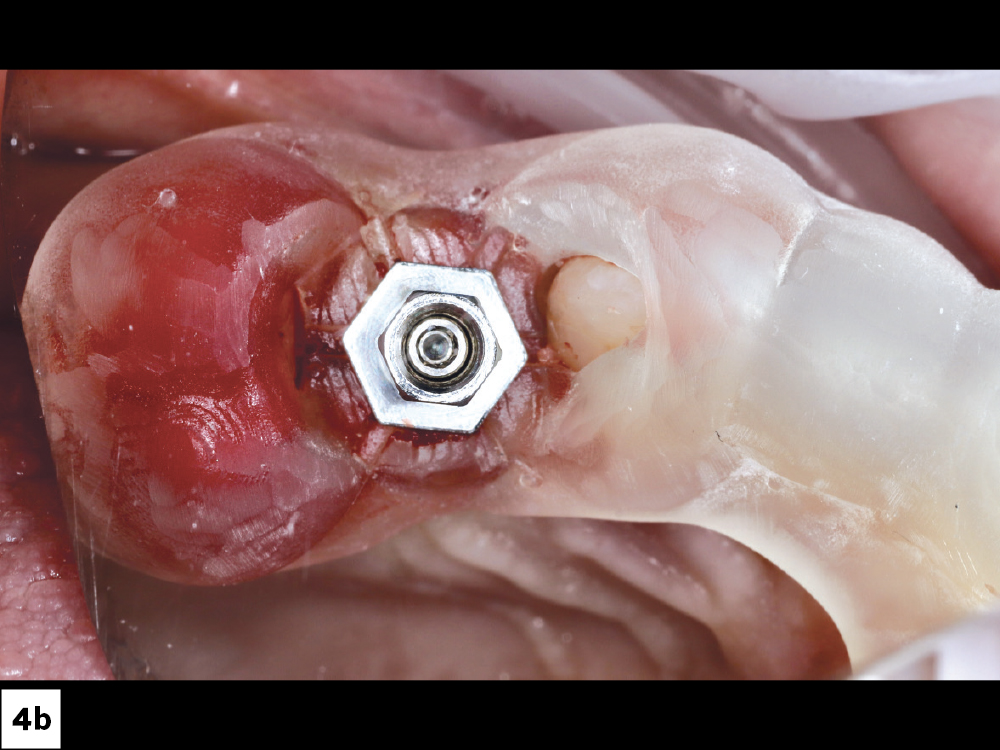

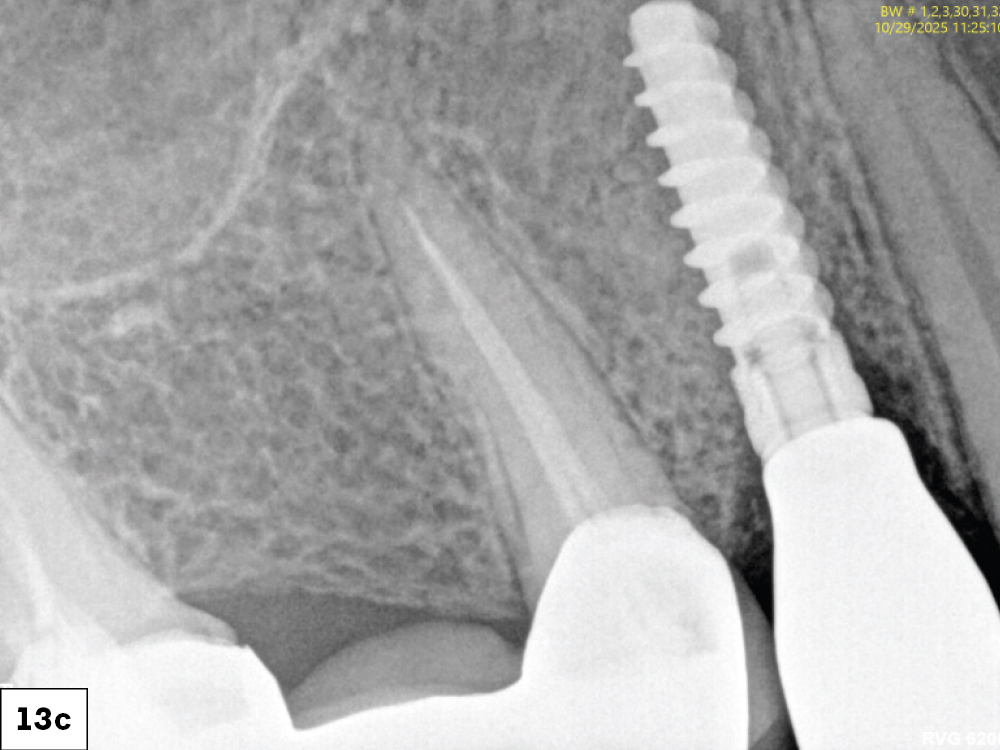

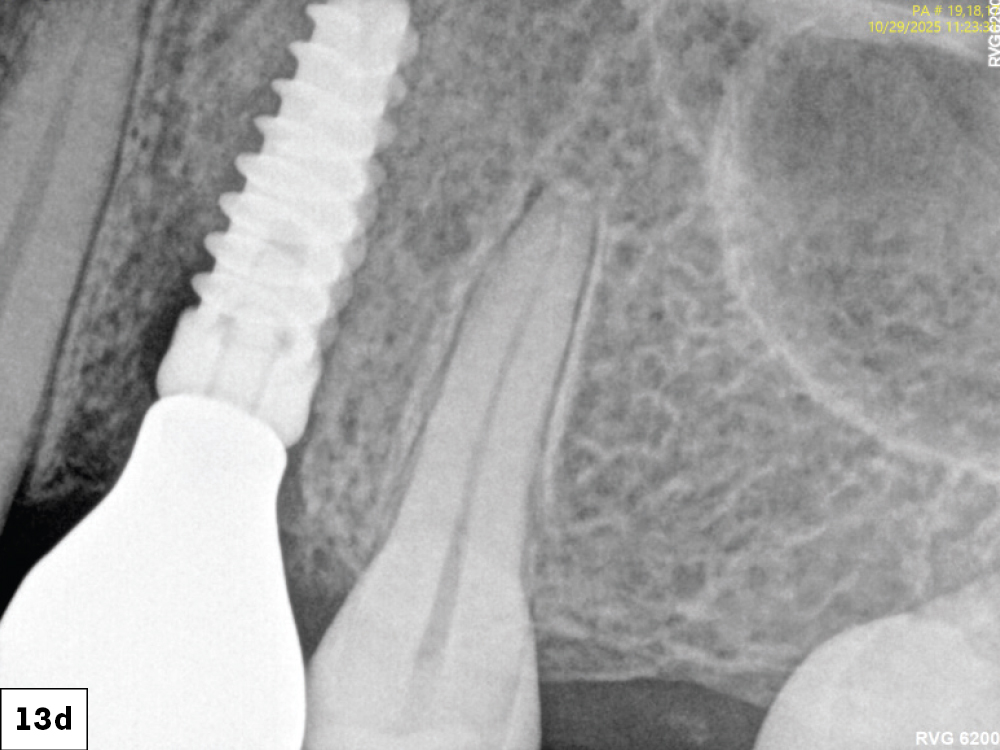

From a biologic perspective, same-day definitive loading under proper conditions supports tissue preservation. The implants in this case were placed with high primary stability, allowing for immediate functional loading within physiological limits. The zirconia crowns provided a rigid, stable interface that guided soft-tissue maturation from day one. By grafting at the thinner site, natural bone contours were maintained, reducing surgical morbidity and healing time. The tissue healed predictably around the definitive form without repeated trauma or remodeling.

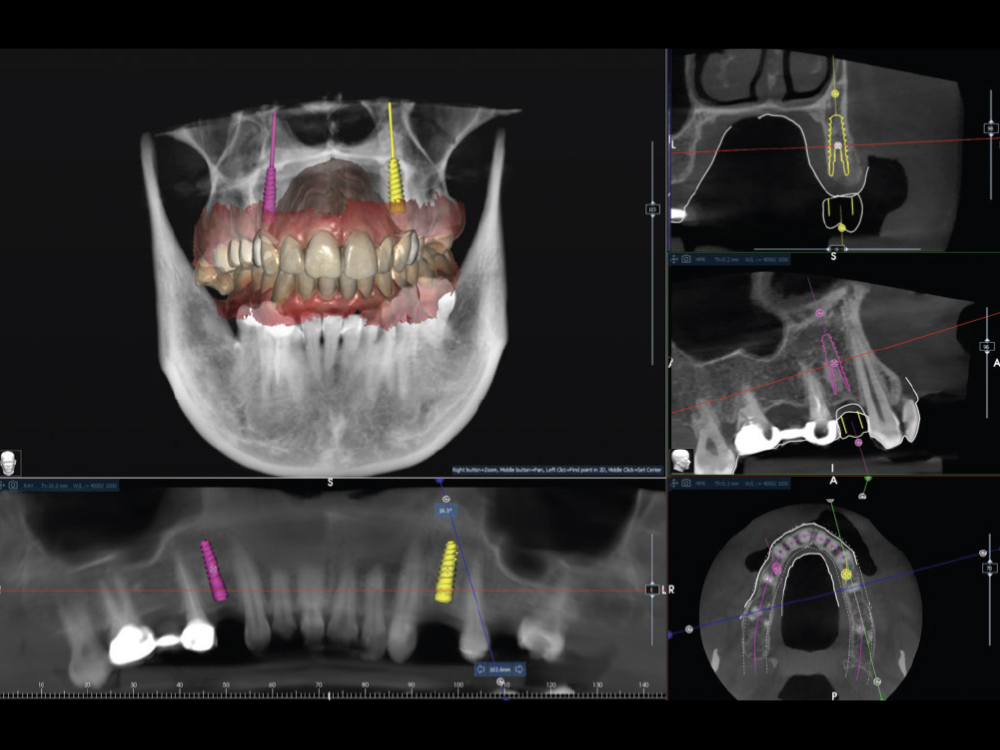

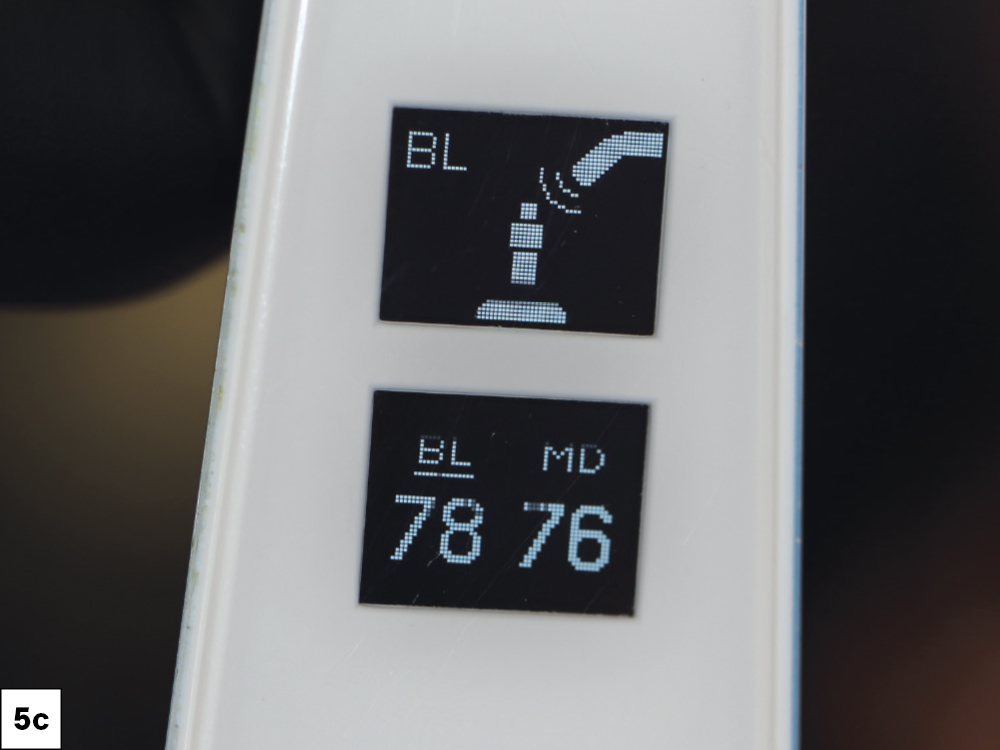

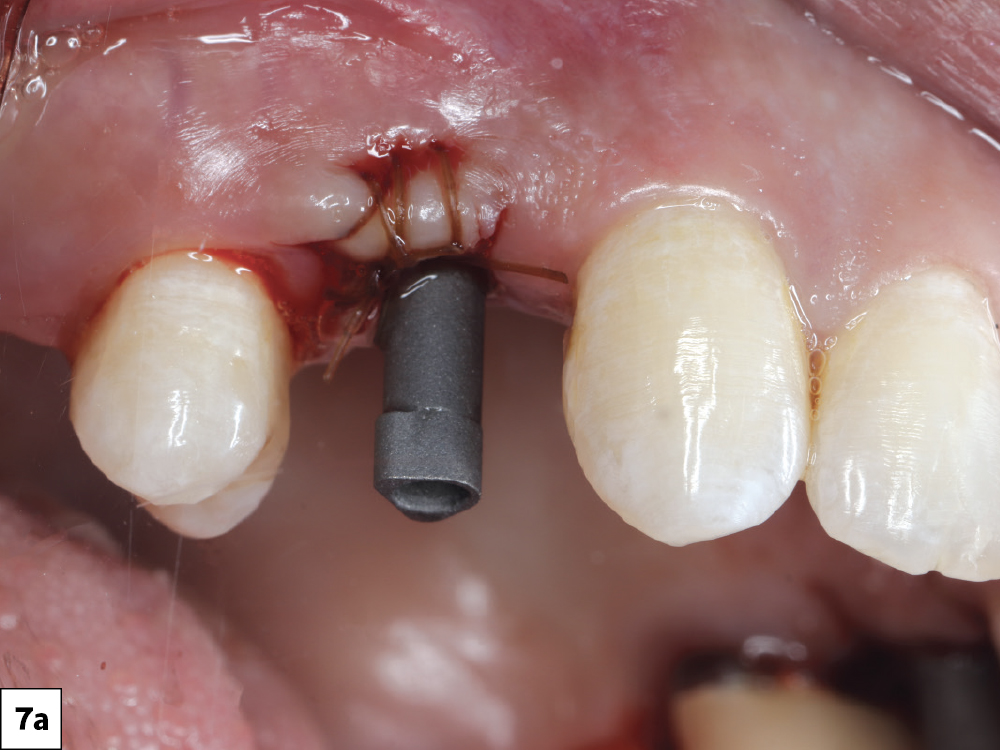

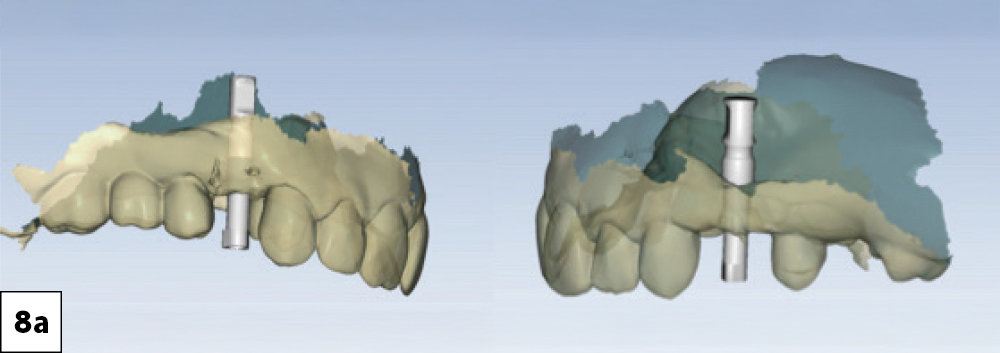

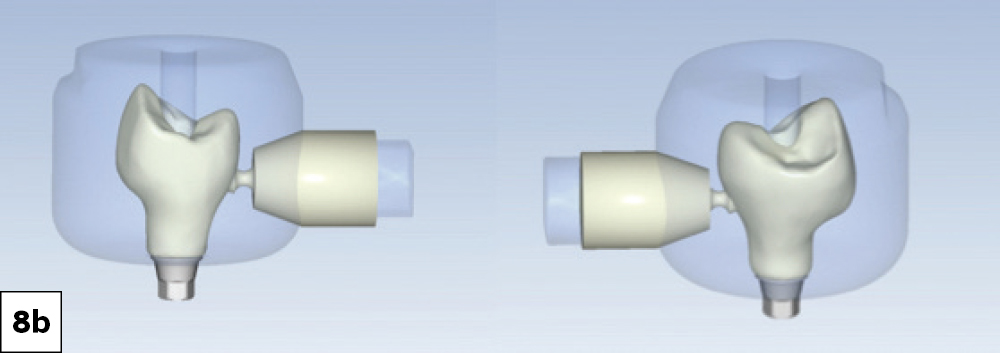

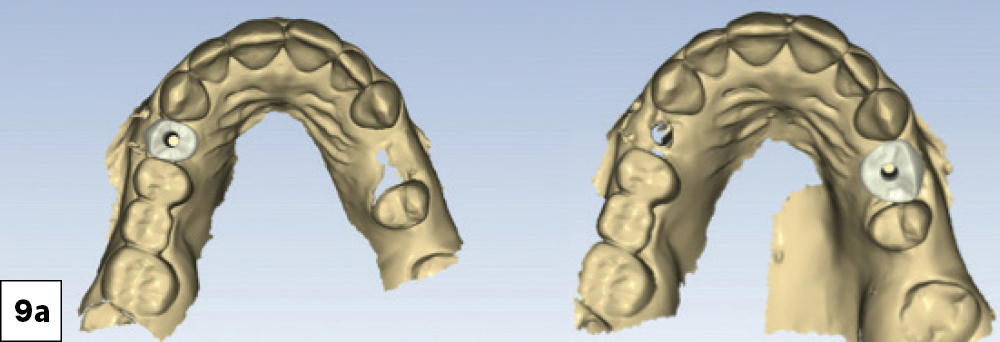

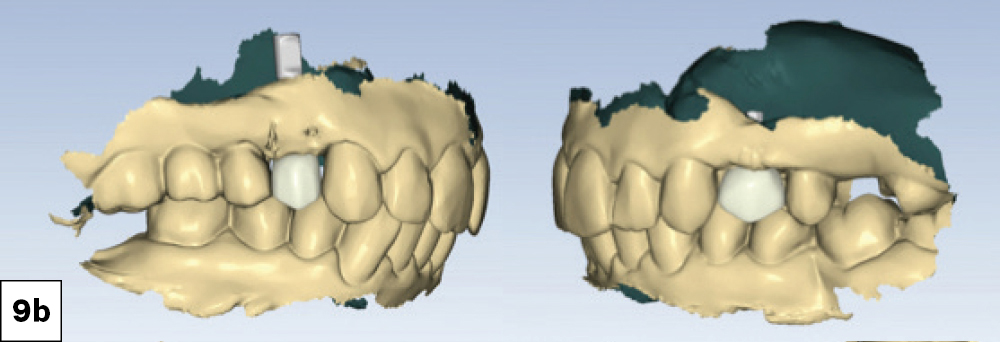

Digitally integrated workflows also enhance precision. Guided implant placement through Glidewell’s DTP department ensured the implants were aligned along the ideal restorative axis, facilitating screw-retained design and eliminating off-angle screw access. Intraoral scanning provided digital accuracy beyond what traditional impression materials could achieve, capturing the true position of the scan bodies without distortion. The fastdesign.io software translated that data directly into restorations that matched the virtual plan with negligible deviation. The combination of these systems, each digitally communicating within the same ecosystem, created a closed loop of accuracy from surgical plan to final restoration.

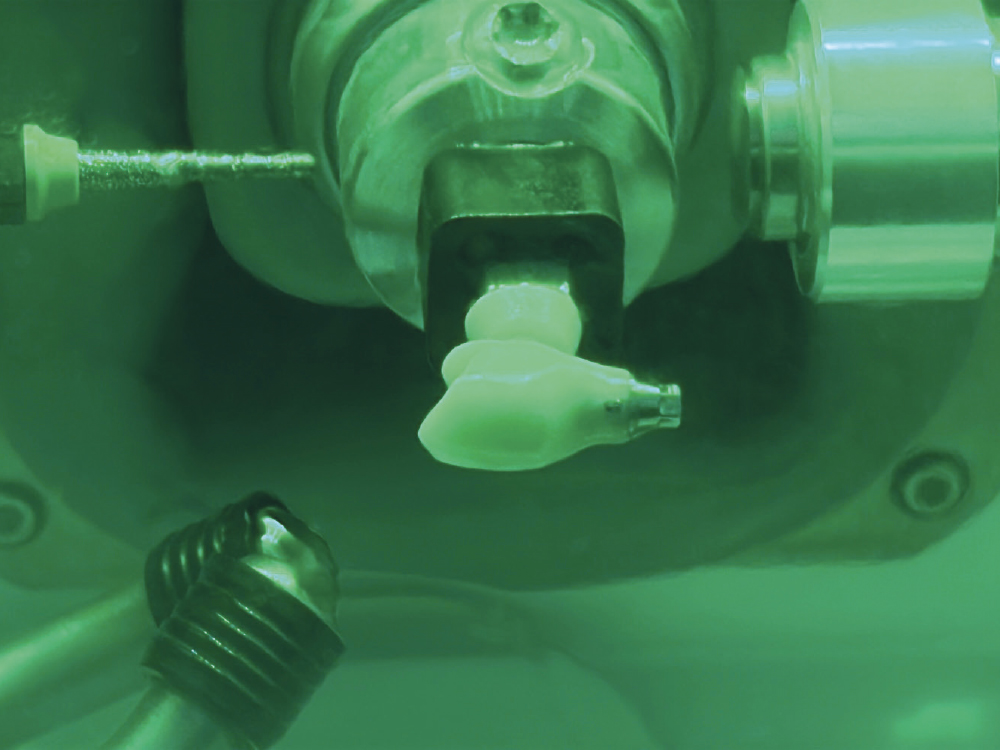

Efficiency is another defining benefit. Although the digital planning was completed a few days prior through Glidewell’s DTP department, the clinical execution from guide fabrication to surgery, design, and milling was accomplished in a single appointment. The guided plan was received digitally within a day, the sleeveless guide printed in twenty minutes, surgery completed in about an hour, design in 10 minutes, and milling finished within forty minutes. This level of integration and speed would have been unimaginable only a few years ago. Traditional workflows often require three to four visits and weeks of laboratory coordination.

The patient’s satisfaction reflected the clinical success. She left the office with definitive restorations, avoided the inconvenience of temporaries, and resumed normal activities the same day. Beyond function and esthetics, same-day treatment restored her confidence immediately and minimized postoperative discomfort.

For the clinician, integrating this digital workflow offers both precision and independence. The ability to scan, design, and mill screw-retained zirconia crowns in-office elevates quality control and eliminates delays tied to laboratory coordination. The process reduces variability, shortens turnaround time, and keeps the entire restorative sequence within the practice while freeing valuable chair time for additional cases.

This case illustrates the new standard for same-day implant rehabilitation. The combination of Glidewell HT Implants, a sleeveless surgical guide printed in-office, along with the fastmill.io and fastdesign.io systems, allows clinicians to produce definitive screw-retained zirconia restorations immediately after placement without sacrificing accuracy or durability. The pre-attached Ti-base design simplifies fabrication, and the integration of advanced glidewell.io scanning further enhances efficiency.

Ultimately, this workflow emphasizes tissue preservation through precision. The result is a streamlined, minimally invasive approach that delivers both biological integrity, superior esthetics and patient satisfaction.

For today’s clinician, the ability to provide screw-retained, fully sintered zirconia restorations within a single visit represents the culmination of digital evolution. The workflow is efficient, predictable, and transformative, turning what was once exceptional into the new standard of care.