glidewell.io™ Users Share Their Favorite Restorative Materials

Clinicians from across the nation spoke with Chairside® magazine to discuss the optimized biomaterials that have become their go-to options for the fastmill.io™ In-Office Mill. Here are some of their stories.

Paresh B. Patel, DDS

Advanced Dentistry of Lenoir

Lenoir, North Carolina

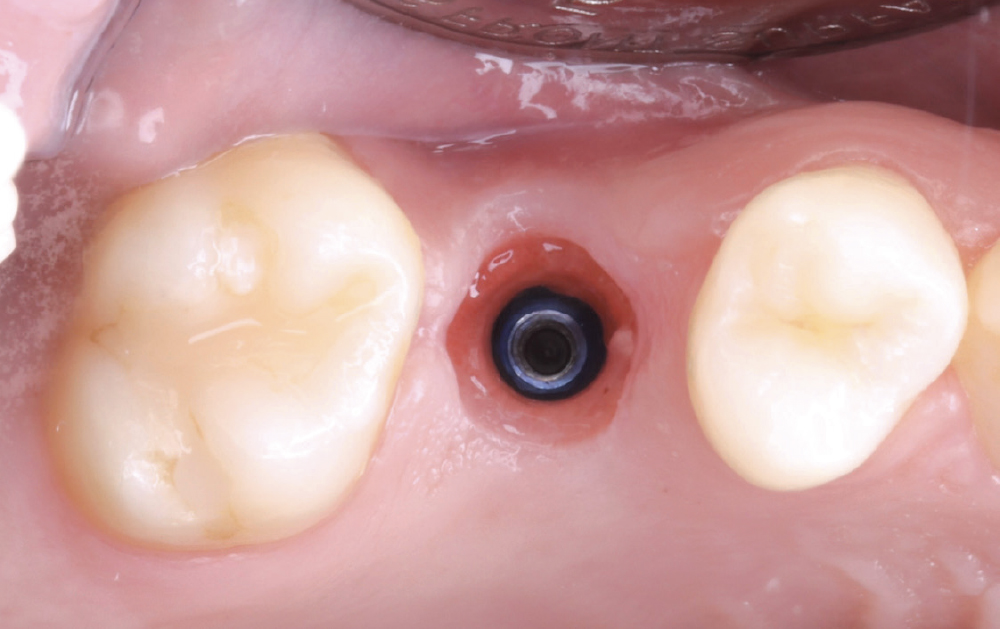

For Dr. Paresh Patel, the introduction of BruxZir® NOW SRC Milling Blocks has added the convenience of screw-retained implant restorations to his list of same-visit treatments. “I love the BruxZir NOW SRC Milling Blocks because the product is straightforward and predictable,” said Dr. Patel. “My assistant puts a scan body in, takes the X-ray, and I verify that the two components fit well together. She then scans it and sends it to the fastdesign.io™ Software and Design Station, and it aligns the scanner path with the implant axis, giving you an automatic proposal for the restoration.”

Dr. Patel was initially skeptical about the BruxZir NOW SRC milling times due to the block size but was quickly won over. “I assumed it would take over an hour to mill, but because there’s a screw-retained sleeve already built into it, the fastmill.io™ In-Office Mill only needs to shape the exterior,” he explained. “It was shocking how fast it milled. The turnaround time is similar to a standard BruxZir NOW Milling Block.”

He’s also found that cost is a major benefit. “Who doesn’t want to save money? We’re thrilled that we can do this affordably in-house.” His practice now regularly offers same-day screw-retained restorations, eliminating the traditional two-week wait. “We give patients options during milling: run an errand, sit in the chair, or go to the coffee shop. In around 40 minutes, their crown will be ready,” Dr. Patel said. “It’s truly game changing.”

Patients are impressed not just by the convenience but also by the technology. “We tell them we’ve invited the largest lab in the U.S. into our office. We even give them a tour and show them the mill at work,” he added.

Dr. Patel no longer glazes BruxZir crowns out of the mill. “We polish them and achieve a beautiful pearlescent esthetic that our patients appreciate. If we use the pink wheel, it almost has too much gloss, so we control how much we polish to meet our patient’s preference.”

The workflow has become so seamless that any posterior single- or two-unit case is milled the same day. “Patients love not getting numbed twice or returning for a second visit. It shows we respect their time — and they value that.” For Dr. Patel, delivering full-contour zirconia restorations with speed, savings, and precision has made BruxZir NOW SRC Milling Blocks an essential part of his practice.

Debbie Lee, DMD

Debbie Lee, DMD

New York City, New York

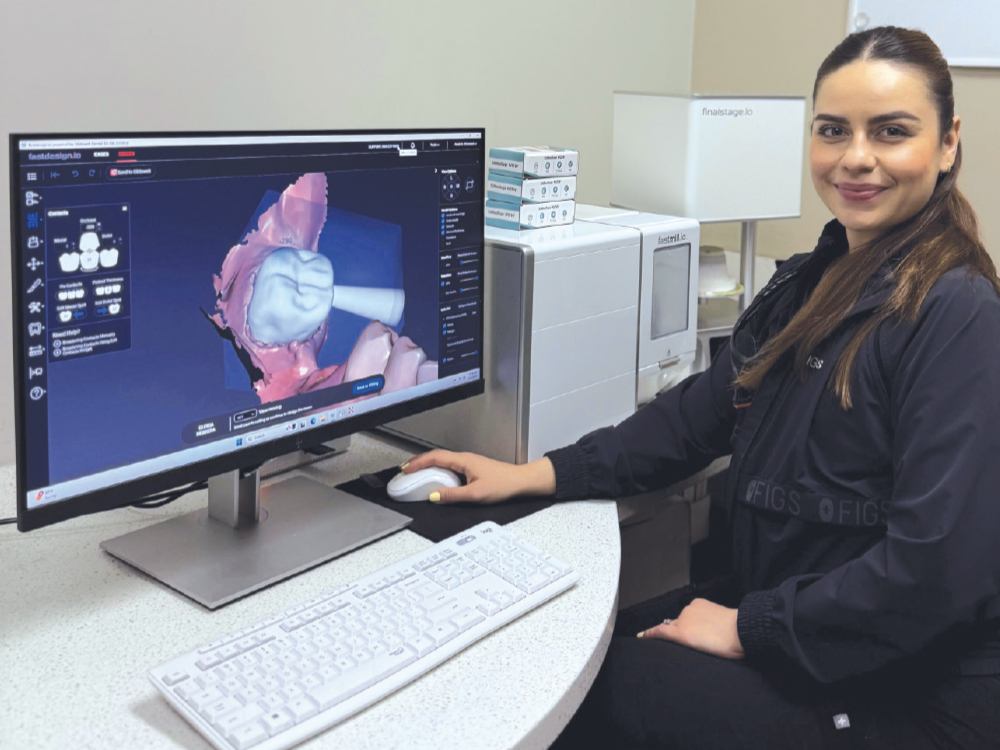

For Dr. Debbie Lee, a solo practitioner in New York City, integrating in-office milling with BruxZir® Esthetic NOW Posterior Milling Blocks has transformed her workflow, patient satisfaction, and profitability.

“My practice is cosmetic-driven, and patients are all about cosmetics nowadays,” Dr. Lee shared. “I love BruxZir Esthetic NOW Posterior Milling Blocks because I can either bond or cement them. The blocks have the strength of BruxZir Zirconia and the esthetics of an IPS e.max® crown.”

The monolithic zirconia material features a flexural strength of 870 MPa and emulates the lifelike properties of natural teeth, allowing Dr. Lee to efficiently deliver high-end cosmetic results. “It gives me more translucency, looks more like enamel, and it’s much more realistic and polished than other zirconia crowns on the market. Also, the shade range is very good because patients’ smiles come in all shades.”

In addition to strength and beauty, BruxZir Esthetic NOW Posterior Milling Blocks provide Dr. Lee with the additional benefit of speed. “I really appreciate the turnaround time of milling a crown in my office,” she explained. “I practice here in New York City where time is very valuable. I have patients who fly back and forth several times to see me — and now I can tell them they can save a trip or two because they’ll be done the same day or the next.”

The success of a dental practice today is intimately tied to the use of technology in supplying convenience, comfort, and high-quality work — and patients take notice. “When they see the mill, they love that it’s high tech. It’s a cool factor for them that I’m designing a computer-assisted crown for their mouth.”

With rising overhead in New York City, the financial impact has been significant. “The fact that I can reduce my lab costs is a game changer. My profits went up because I’m making more crowns myself, keeping the revenue in-house, and lowering my lab fees.”

Josh W. Davis, DDS

Reflection Ridge Dental

Wichita, Kansas

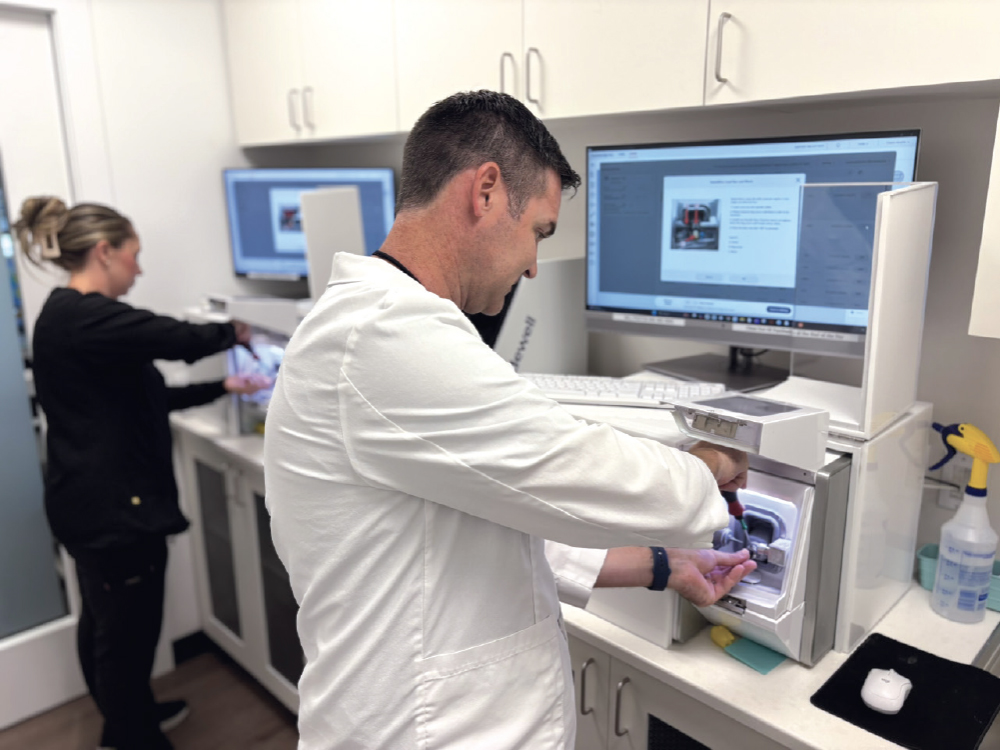

Dr. Josh Davis estimates that 90 to 95 percent of his crown & bridge cases are same-day, single-unit and two-unit crowns. With three fastmill.io™ In-Office Mills running consistently, his team can manage high demand without tying up production. “It’s probably the piece of equipment we use the most. We use them all day.”

“BioTemps® NOW Milling Blocks have become an indispensable material in my practice because of the product’s esthetics and process efficiency,” said Dr. Davis. Known for natural esthetics and precise fit, BioTemps NOW Milling Blocks help Dr. Davis manage tissue healing as well as patient expectations. “The provisionals come out smooth, and the soft tissue responds very well — there’s little redness or bleeding postoperatively. In fact, the esthetics are always good, and it mills fast,” he said.

In complex or anterior cases, Dr. Davis appreciates the ability to contour and shape pontics to guide tissue development. “If I have a healing socket, I can design the pontic exactly where I want the tissue to end up. That’s hard to do by hand, but with BioTemps NOW Milling Blocks, we can digitally design them.”

“I also use BioTemps NOW Milling Blocks in situations like cracked tooth syndrome or when the tooth is mildly symptomatic,” Dr. Davis explained. “We’ll place a temp, let the patient go about their life, and monitor how the tooth responds. That way, if we do have to send the patient to an endodontist, it’s easier to remove the temp and have good access to do the endo treatment, versus having them cut a hole in the patient’s brand-new crown.”

Having high-quality milling blocks like BioTemps NOW provisionals allows for flexibility and a smoother patient experience. “Even though I prefer not to temporize,” he said, “we use a lot of this material — for good reason.”

Gisela Wray, DDS

Wray & Khorsand Dental Group

El Centro, California

For Dr. Gisela Wray, CAMouflage® NOW Milling Blocks have become a go-to restorative material for both esthetics and efficiency. “We do a lot of endo in our practice, so we place a lot of endo crowns,” she explained. “With seven VITA shades to choose from, we’ve found that the CAMouflage NOW material blends beautifully with the natural dentition. I particularly like how fast it mills — it’s ready in under 10 minutes.”

That speed enables Dr. Wray to offer same-day solutions, even in more demanding cases. “It’s very easy to design, even on short teeth. I’ve even delivered same-day veneers using CAMouflage NOW Milling Blocks. We just tell the patient, ‘It’ll be a couple of hours — do you want to hang around?’ And they do. We have TVs in every room, so they relax and watch a show. They’re very, very happy.”

Same-day dentistry is central to Dr. Wray’s workflow. “Everything is same day unless it’s a multi-unit case, which we usually send to the lab. Patients love that they don’t have to come back, get numbed again, or schedule another appointment. They walk in with a broken tooth — and walk out with a new crown.”

Beyond convenience, CAMouflage NOW Milling Blocks have proven to be a productive and patient-pleasing solution. “It increased our efficiency and allowed us to treat more patients in less time,” she said. One patient even surprised her with a simple but powerful comment after receiving their restoration: “It feels like my tooth again.”

For Dr. Wray, that’s the ultimate confirmation that technology is doing what it’s meant to do — restore both smiles and confidence, seamlessly.

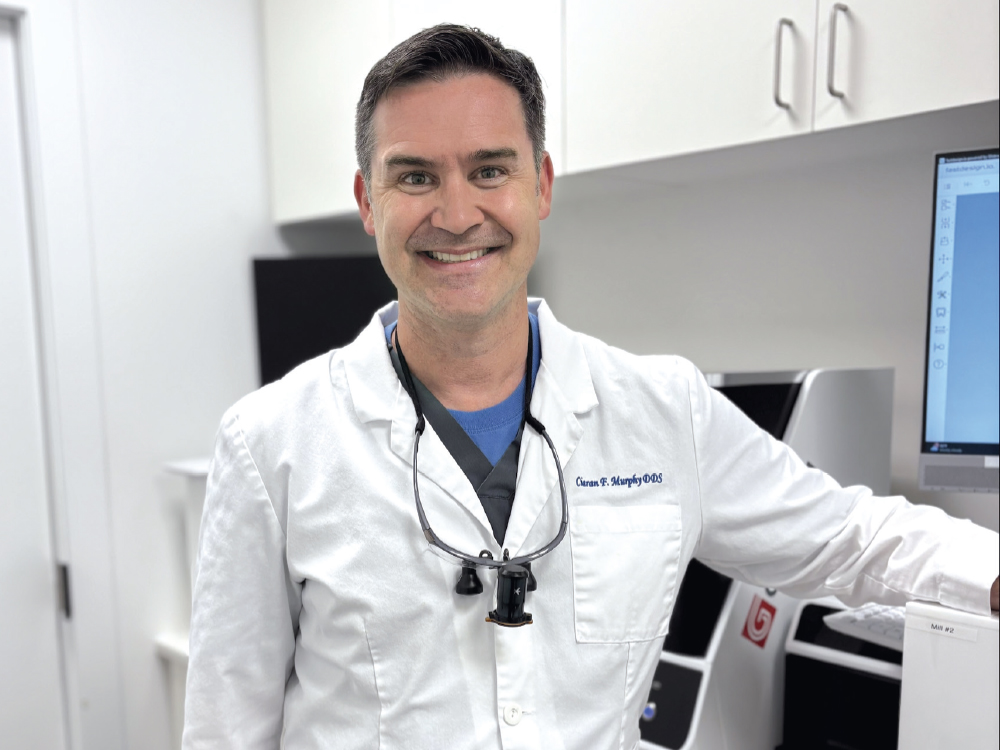

Ciaran F. Murphy, DDS

Harbor Dental

Fort Collins, Colorado

Dr. Ciaran Murphy appreciates the ability of Obsidian® NOW Milling Blocks to deliver lifelike translucency without oven time. “While it’s a great material for use from canine to canine, I also use it on premolars, especially in cases where the patient exhibits a large smile,” said Dr. Murphy. “It provides strength with a nice esthetic finish. And because you don’t need to fire it, you get a beautiful result quickly.”

Obsidian NOW has become a key material in Dr. Murphy’s same-day arsenal. “Once it is out of the mill, Obsidian NOW takes just 30 seconds of polishing for a fantastic shine,” said Dr. Murphy. “You don’t even need to glaze it.”

Efficiency and patient satisfaction are central to Dr. Murphy’s practice philosophy. “One major benefit of the glidewell.io™ system has been staff empowerment,” he said. “With in-office milling, assistants can scan, design, and mill crowns regardless of their certification level. It gives them a valuable skill, increases job satisfaction, and frees me up clinically.”

That operational flexibility has expanded over time. “Once you get a mill, you quickly realize how helpful it would be to have two. We now use both machines all day,” said Dr. Murphy.

From a marketing perspective, same-day service has become a key differentiator. “Patients call our office because they’ve been told they need a crown and are looking for same-day treatment,” explained Dr. Murphy. “It’s one of the top drivers of new patient intake.”

Ultimately, Dr. Murphy sees Obsidian NOW as a high-performance material that balances convenience, quality and esthetics. “It’s a fantastic material that fits the way we practice dentistry today,” he said.